Films and articles with reversible opacity change upon stretching, and methods of making and using same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

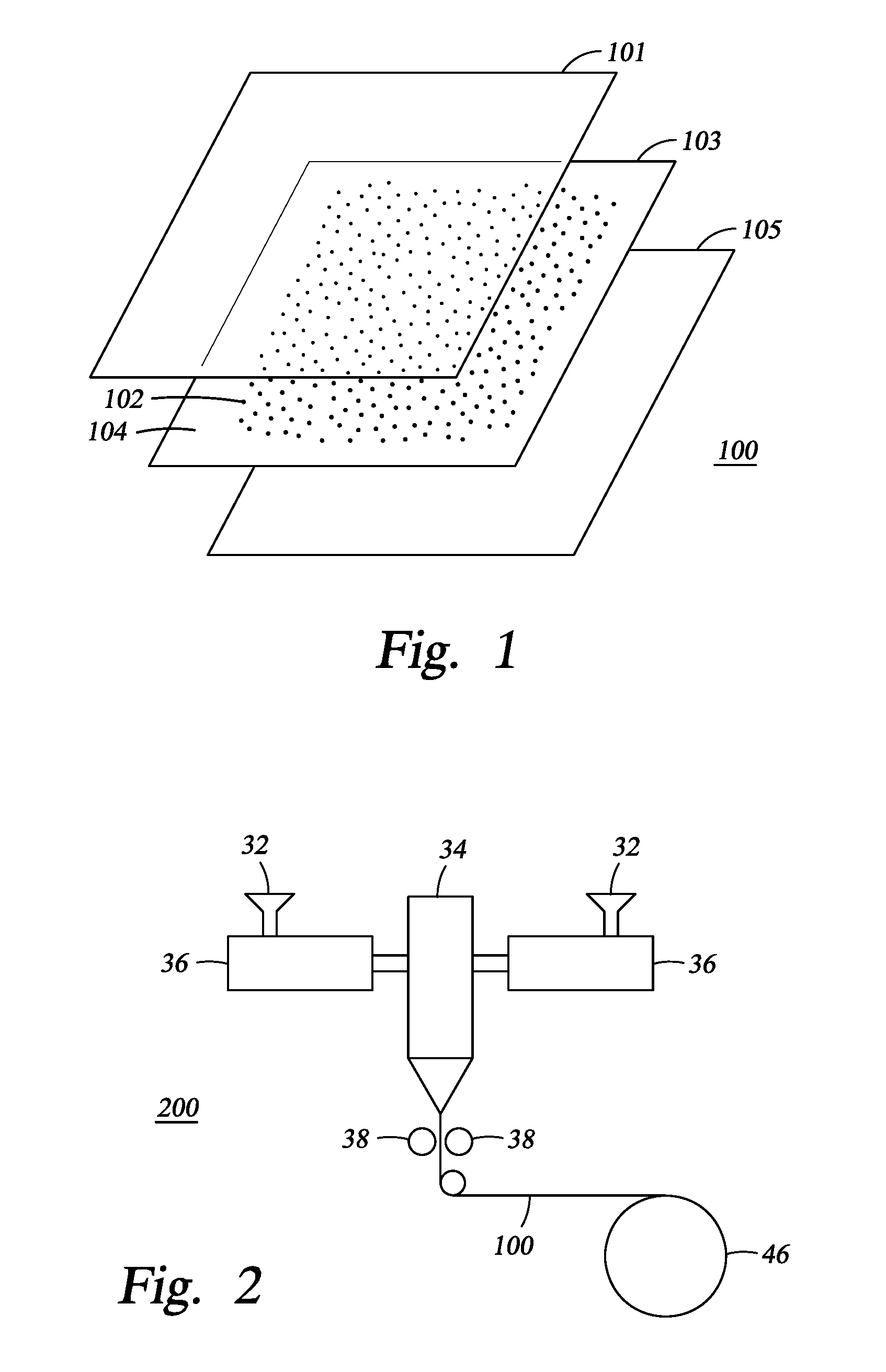

[0062]In one embodiment of the invention a film was synthesized as described in relation to FIG. 2. The following resins were combined in a hopper and extruded at about 400° F. through a standard film die at a through speed of about 51 feet / min onto a casting roll maintained at about 70° F.:[0063]Low crystallinity transparent elastomer: Exact 5361, about 86 wt %,[0064]Medium crystallinity elastomer: Vistamaxx 1100, about 10 wt %, and[0065]Crystallite: PP 3155, about 4 wt %.

[0066]Exact 5361, Vistamaxx 1100, and PP 3155 are polymer resins manufactured by ExxonMobil Chemical. Exact 5361 is an ethylene octene copolymer with a melt index of 3 g / 10 min at 190° C. and a melt flow rate of 5.6 g / 10 min at 230° C. and a polymer density of 0.86 g / cm3. Vistamaxx 1100 is an olefin elastomer with a melt index of 3 g / 10 min at 190° and a polymer density of 0.86 g / cm3 which exhibits propylene type of crystallinity. 3155 PP is a fiber grade polypropylene with a melt flow rate of 35 g / 10 m

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Crystallinity | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap