Elevator brake of novel structure

A technology of elevator brake and new structure, which is applied in hoisting devices and other directions, can solve the problems of increased process difficulty, increased processing difficulty, and high cost, and achieves the effects of easy manufacturing, low design and processing costs, and less material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

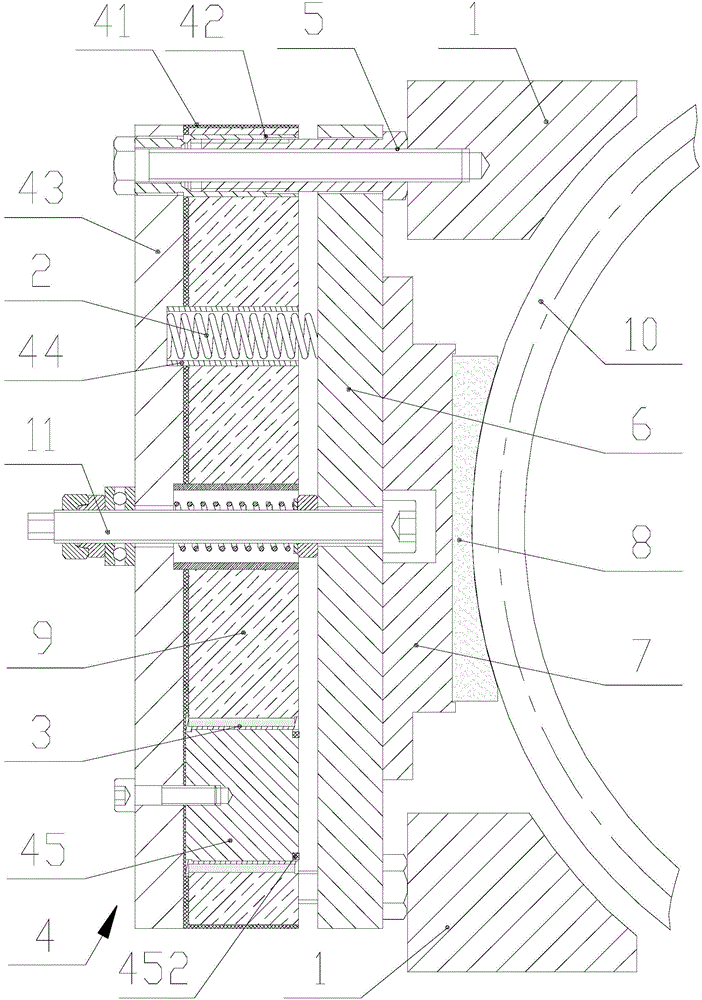

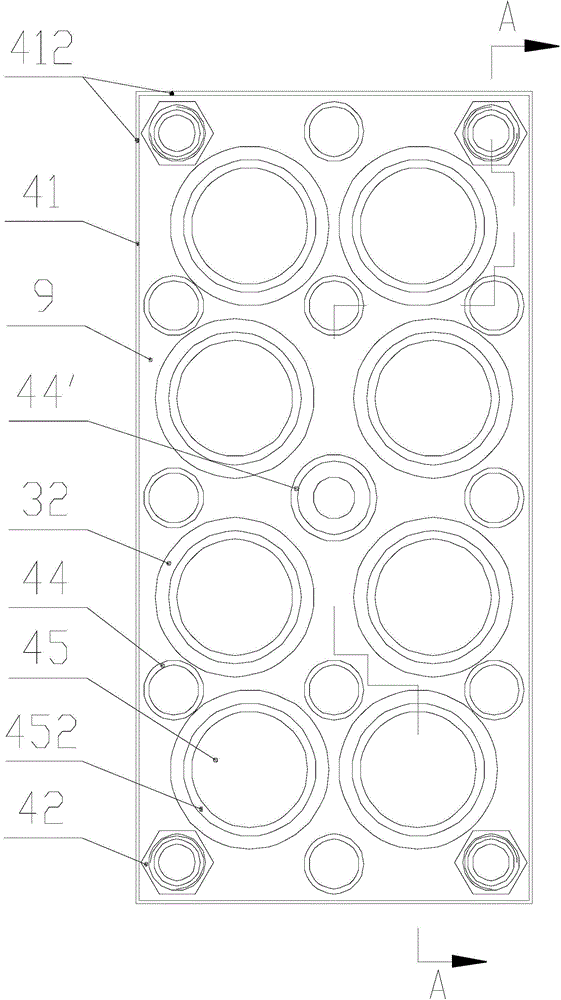

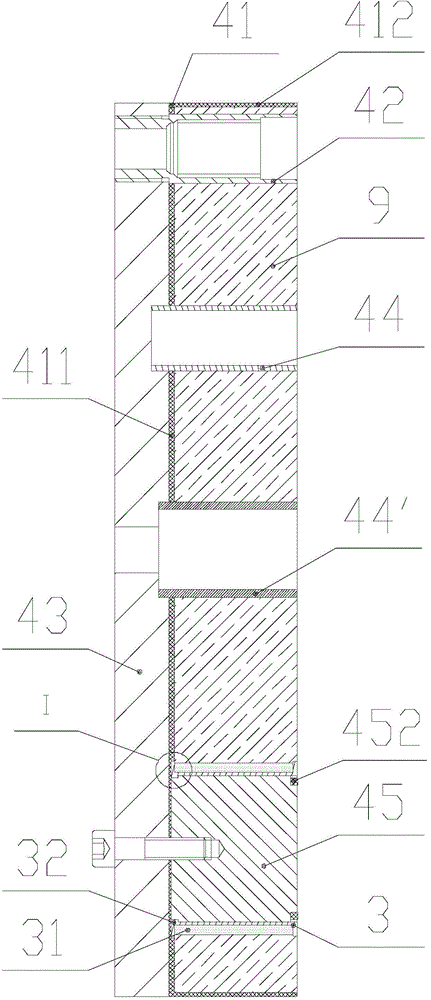

[0024] Such as figure 1 and figure 2 As shown, a new type of elevator brake includes a hub 1, a spring 2, a coil winding 3, a guide post 5, an armature 6, a tongue plate 7 and a friction plate 8 arranged on the tongue plate 7, and the armature 6 is installed On the guide post 5 and can move along the guide post 5, the tongue plate 7 is fixed on the armature 6, the brake also includes an assembly fixing seat 4, and the assembly fixing seat 4 includes a frame shell 41, a fixing plate 43, a spring fixing Cover 44 and iron core 45; the frame shell 41 and the spring fixing sleeve 44 are all arranged on the fixed plate 43; the iron core 45 is at least one, and the iron core 45 is arranged on the fixed plate 43 and is located in the frame shell 41; The coil winding 3 is arranged on the iron core 45, the two ends of the guide post 5 are respectively fixedly connected to the fixed p

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap