Dedusting equipment and using method thereof

A technology of dust removal equipment and dust removal chamber, which is applied in the field of dust removal equipment and foundry dust removal equipment, can solve the problems of reduced work efficiency of dust collectors, forgetting to turn off dust collectors, useless power of dust collectors, etc., and achieves simple improvement, simplified operation, and reduced energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate understanding of the present invention, the present invention will be more fully described below in conjunction with specific embodiments and with reference to related drawings. Preferred embodiments of the invention are shown in the accompanying drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein. On the contrary, the purpose of providing these embodiments is to make the disclosure of the present invention more thorough and comprehensive.

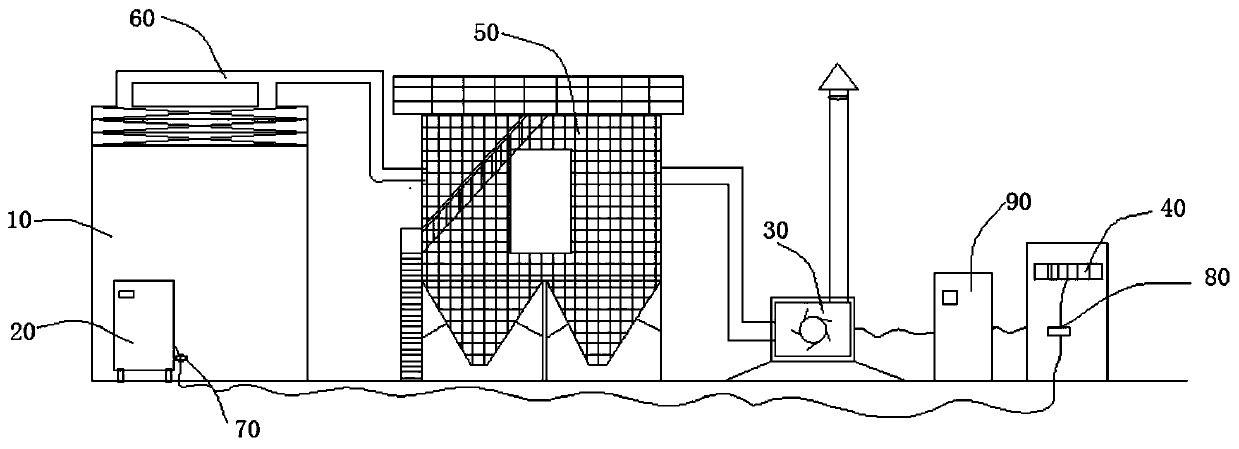

[0023] A kind of dust removal equipment, please refer to the attached figure 1 As shown, it includes a dust removal chamber 10, a gouging machine 20, a dust removal fan 30, a PLC control system 40, a dust remover 50, and a dust removal pipeline 60; The dust remover 50 communicates with the dust remover 50 through the dust removal pipeline 60, and the dust remover fan 30 communicates with the dust remover 50; , the current trans

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap