Ceramic tile production equipment facilitating dust removal

A technology for production equipment and ceramic tiles, which is applied in the field of ceramic tile production equipment that is convenient for dust removal, can solve problems affecting production efficiency and losses, and achieve the effects of simple structure, dust suppression, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

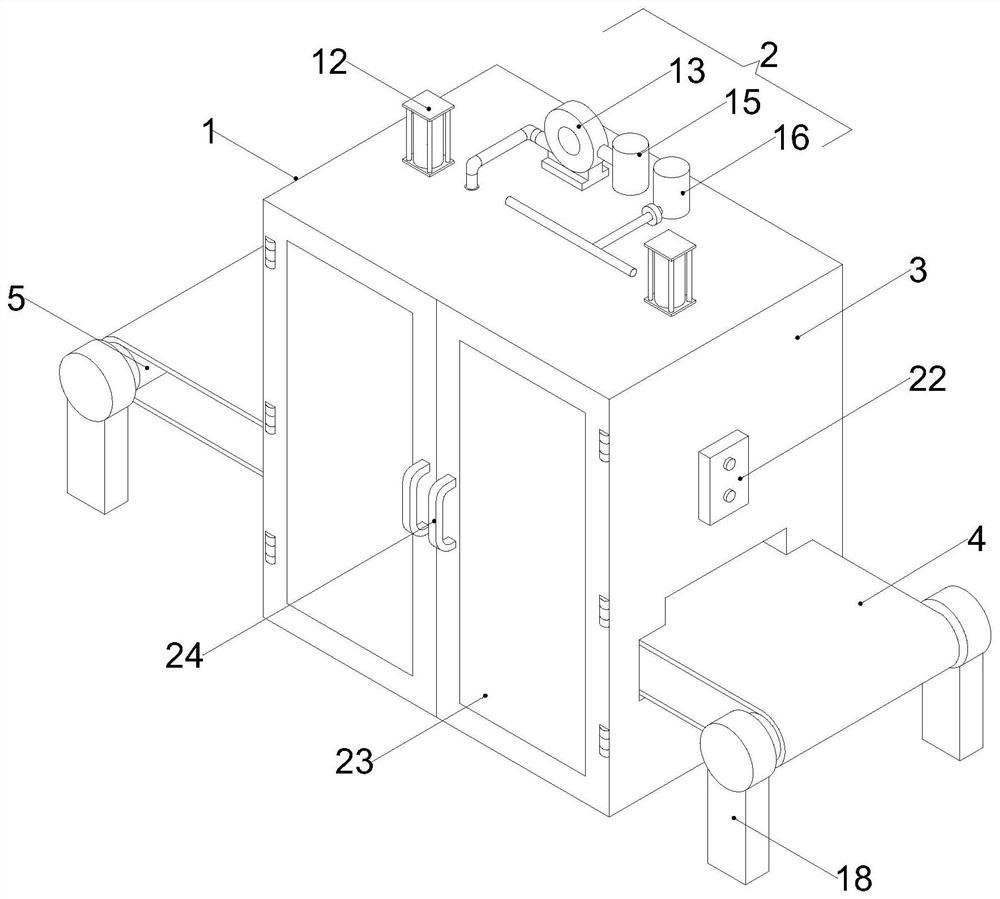

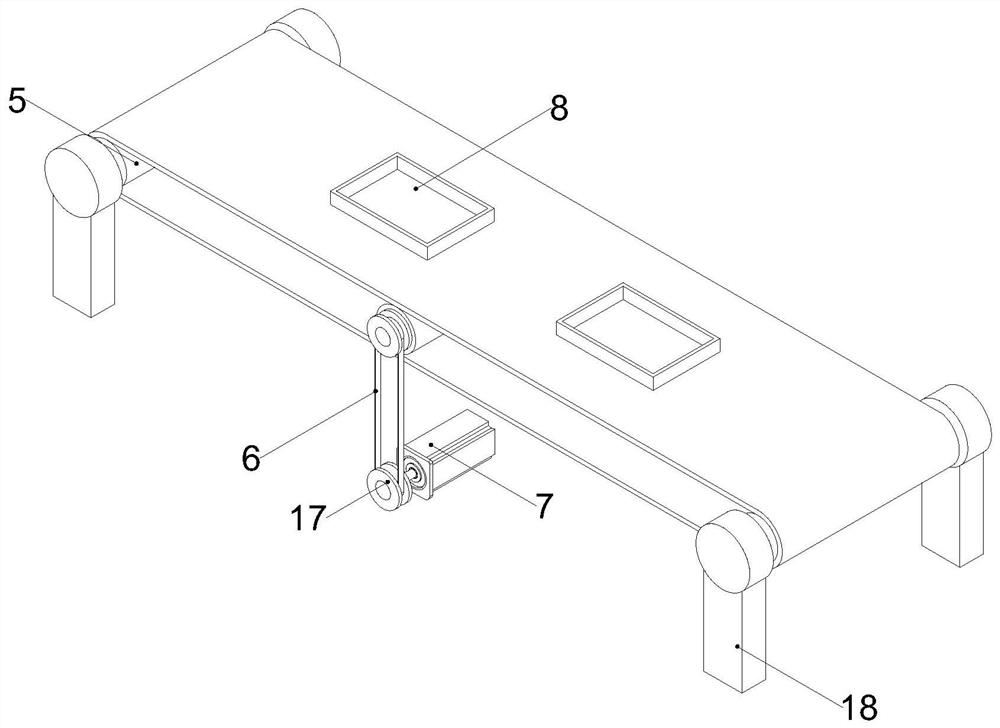

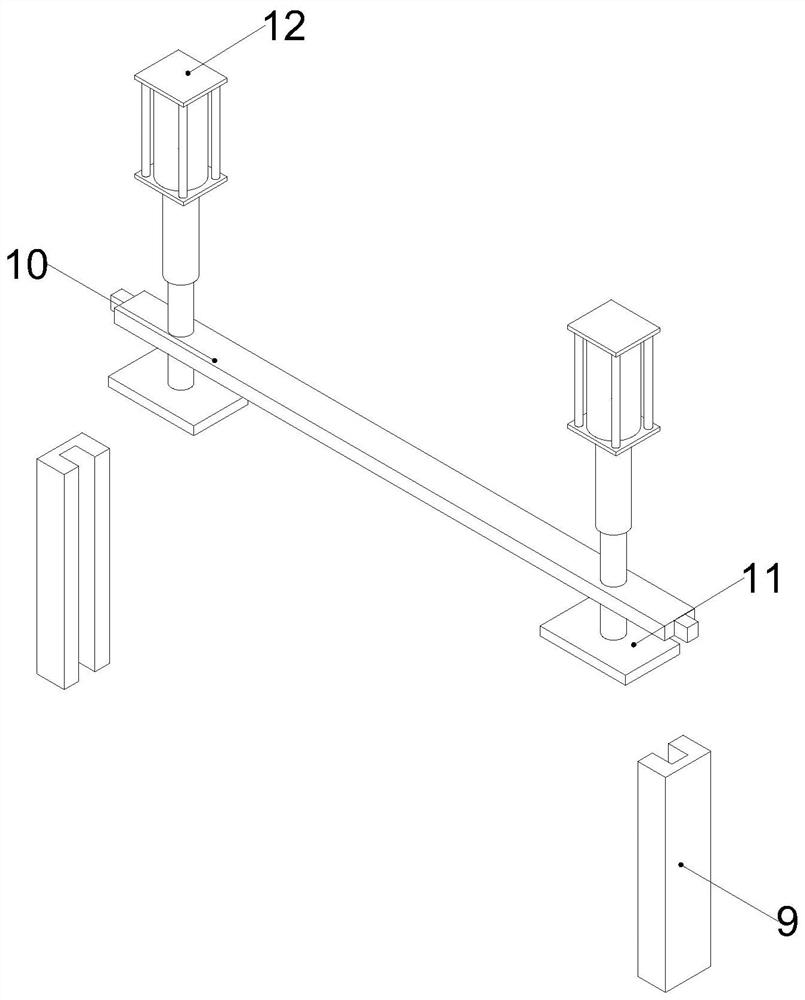

[0021] Example: such as Figure 1-Figure 4 As shown, the present invention is a kind of ceramic tile production equipment that is convenient for dust removal, including a production equipment body 1 and a dust removal mechanism 2. The production equipment body 1 includes a box body 3, a conveyor belt 4 is arranged inside the box body 3, and three conveyor belts are arranged inside the conveyor belt 4. A rotating shaft 5, one end of the rotating shaft 5 in the middle of the three rotating shafts 5 is provided with a rotating belt 6, one side of the bottom end of the rotating belt 6 is provided with a drive motor 7, the middle part of the conveyor belt 4 top is provided with a stamping groove 8, and the box body 3 Both sides of the interior are provided with chute 9, the interior of the two chute 9 is provided with a slide plate 10, both sides of the bottom of the slide plate 10 are provided with stamping blocks 11, both sides of the top of the box body 3 are provided with a push cy

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap