Energy-saving environment-friendly low-noise desulfurization, denitrification and dust removal device and treatment method

A desulfurization and denitrification, energy saving and environmental protection technology, applied in the field of flue gas treatment, can solve environmental pollution and other problems, achieve the effect of improving reaction effect and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

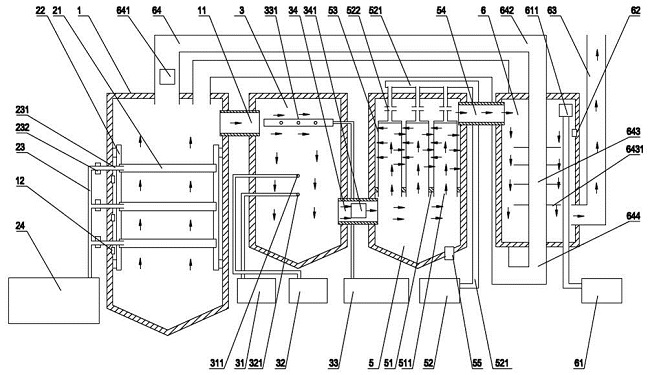

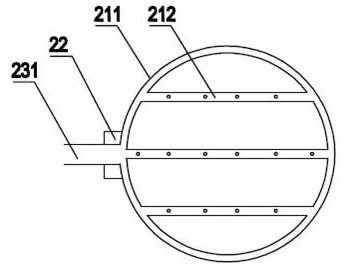

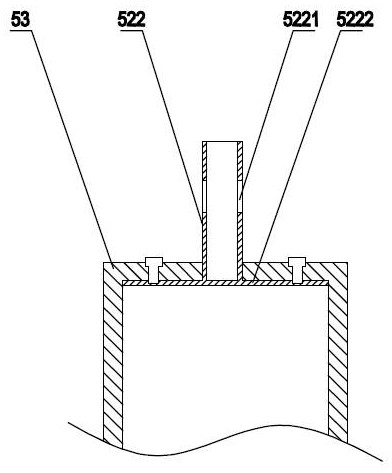

[0028] Such as Figure 1 to Figure 3As shown, according to the present embodiment 1, an energy-saving and environment-friendly low noise desulfurization, denitrification and dust removal device comprises a furnace body 1, a desulfurization tower 3, a dust removal tower 5 and an SCR reaction tower 6, and the furnace body 1 is fixedly connected with The fixed frame 22, the upper part of the right side wall is provided with the first connecting pipe 11, the top is connected with the flue gas drainage pipe 64 and the return pipe 644, and the outside is provided with the urea solution injector 24, and the fixed frame 22 is connected with multiple groups of injection An annular body 21, the injection annular body 21 includes a hollow outer annular ring 211 and a plurality of transverse tubes 212 transversely connected in the outer annular ring 211, the transverse tubes 212 are provided with multiple groups of injection holes, The urea solution injector 24 is connected with multiple gro

Embodiment 2

[0040] According to the treatment method of an energy-saving and environment-friendly low-noise desulfurization, denitrification and dust removal device in Example 2, the energy-saving and environment-friendly low-noise desulfurization, denitration and dust removal device is applied, and the treatment method includes the following steps:

[0041] The flue gas generated by fuel combustion at the bottom of the furnace body 1 reacts with the urea solution sprayed by the injection ring 21 in the furnace body 1, and the nitrogen oxides in the flue gas are reduced to nitrogen and water, and then flow into the first connecting pipe 11 to remove In the sulfur tower 3, the lime slurry solution sprayed by the lime slurry injection pipe 331 reacts to generate salt and water and cools down, and then reacts with the sodium hydroxide and activated carbon powder sprayed from the injection head 1 311 and the injection head 2 321 to reduce the temperature of the smoke. The sulfur oxides and heavy

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap