Superfine modified aluminum hydroxide flame retardant, preparation method and preparation equipment

An aluminum hydroxide flame retardant, aluminum hydroxide technology, applied in chemical instruments and methods, fibrous fillers, dyeing physical treatment, etc., can solve the problem of poor polyester reaction effect, poor flame retardancy of polyester, occupation Site space and other issues, to achieve the effect of ensuring fineness, improving the response effect, and reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

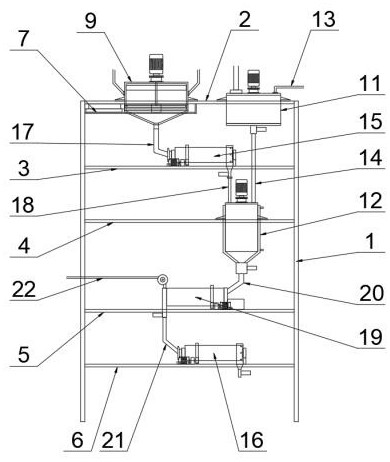

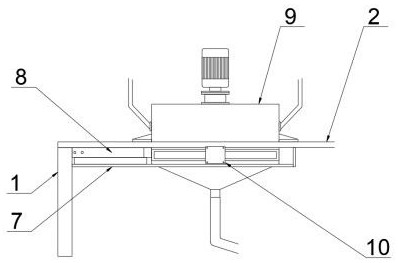

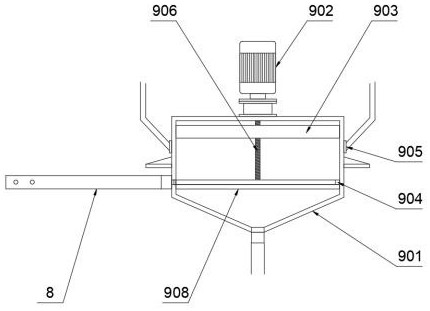

[0038] Method for preparing modified ultrafine aluminum hydroxide flame retardant, comprising the steps of:

[0039] Step 1: The surface modifier and dispersing agent are added to water, respectively, and stirring, resulting in a mixed solution;

[0040] Step 2: Put the aluminum hydroxide fine powder and trioxide fine powder into the rolling apparatus for rolling to obtain a crude mixture;

[0041]Step 3: Introducing the crude mixture into a coarse ball mill for ball milling, when the particle size is less than 4 μm, the mixed powder is introduced into the mixer;

[0042] Step 4: The mixed solution is then introduced into the mixer, and the temperature is provided to 75 to 85 ° C, and mixed with the mixed powder to obtain a mixture;

[0043] Step 5: The mixture was introduced into the dryer for drying, and then the dried mixed material was introduced into the fine ball mill for ball milling, until the particle size was less than 1 μm to obtain ultrafine modified aluminum hydroxide fl

Example Embodiment

[0046] Example 1:

[0047] Ultrafine aluminum-modified flame retardants, parts by mass of the material prepared from: 16 parts aluminum hydroxide powder, 1 part of a surface modifying agent, 4 parts of antimony trioxide powder, 1 part of a dispersant.

[0048] Prepared according to the present embodiment, comprising the steps of:

[0049] Step 1: The surface modifier and dispersing agent are added to water, respectively, and stirring, resulting in a mixed solution;

[0050] Step 2: Put the aluminum hydroxide fine powder and trioxide fine powder into the rolling apparatus for rolling to obtain a crude mixture;

[0051] Step 3: Introducing the crude mixture into a coarse ball mill for ball milling, when the particle size is less than 4 μm, the mixed powder is introduced into the mixer;

[0052] Step Four: The mixed solution was then introduced into the mixer, the temperature was set to 75 ℃, stirred and mixed with a mixed powder to obtain a mixed material;

[0053] Step 5: The mixture

Example Embodiment

[0054] Example 2:

[0055] Ultrafine aluminum-modified flame retardants, parts by mass of the material prepared from: 18 parts aluminum hydroxide powder, surface modifiers 2, 6 antimony trioxide powder, a dispersing agent.

[0056] Prepared according to the present embodiment, comprising the steps of:

[0057] Step 1: The surface modifier and dispersing agent are added to water, respectively, and stirring, resulting in a mixed solution;

[0058] Step 2: Put the aluminum hydroxide fine powder and trioxide fine powder into the rolling apparatus for rolling to obtain a crude mixture;

[0059] Step 3: Introducing the crude mixture into a coarse ball mill for ball milling, when the particle size is less than 4 μm, the mixed powder is introduced into the mixer;

[0060] Step Four: The mixed solution was then introduced into the mixer, the temperature was set to 80 the mixed powder were mixed and stirred to obtain a mixed material;

[0061] Step 5: The mixture was introduced into the dryer

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap