Dandelion beverage and preparation method thereof

A technology of dandelion and dandelion extract is applied in the directions of food ingredients containing natural extracts, food ingredients as taste improvers, food ingredients as odor improvers, etc., which can solve problems such as unfavorable processing, low stability, poor taste, etc. The effect of excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

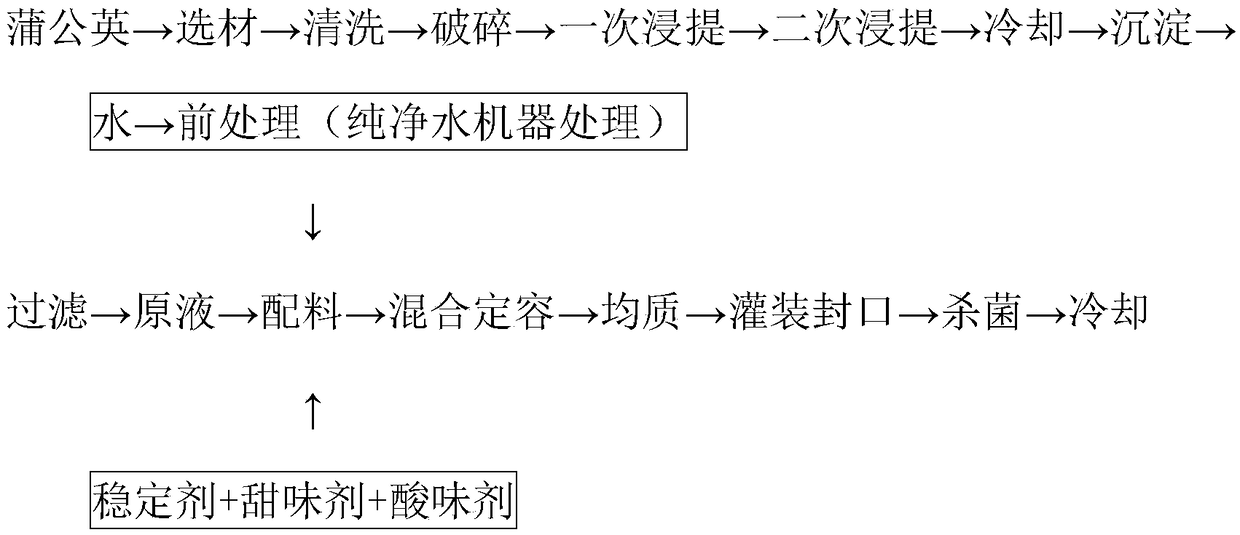

Method used

Image

Examples

Example Embodiment

[0043] Example 1: Preparation of dandelion beverage

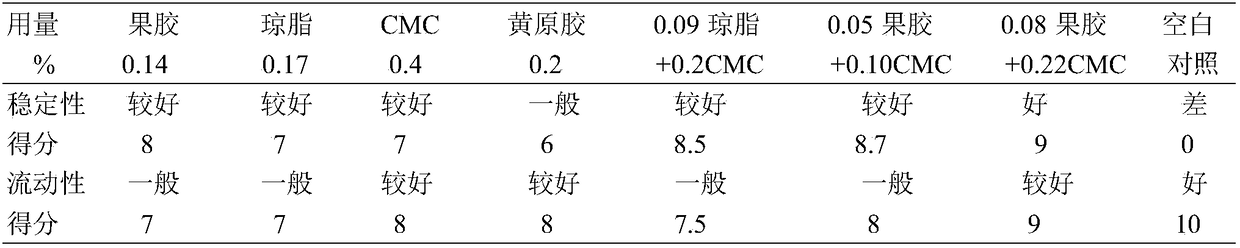

[0044] Take 12Kg of dandelion stems and leaves and 18Kg of dandelion root mixed raw materials, wash, break, add 30Kg of water, and extract at 100°C for 40 minutes by percolation method to obtain 50Kg of dandelion extract mixture. Take 1Kg of carboxymethyl cellulose and 500g of pectin and mix; then take 80Kg of sucrose and 2Kg of honey and mix; use the 1.5Kg of beverage stabilizer mixture obtained above at a temperature of 68℃ and a stirring speed of 1200r / min. The 82Kg sweetener is microencapsulated until the microcapsules have a particle size of 0.5μm, and they are sieved twice with 200 mesh. Take the dandelion extract mixture and stabilizer sugar solution obtained above, add 1.7Kg of citric acid, 0.3Kg of sodium citrate, and mix, add 864.5Kg of purified water, stir and mix.

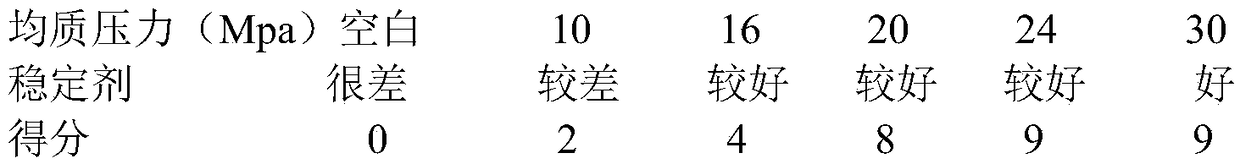

[0045] The mixed liquid obtained above was allowed to stand for 24 hours under a pressure of 20Mpa to obtain a homogeneous mixed liquid. Sterilize at 10

Example Embodiment

[0046] Example 2: Preparation of dandelion beverage

[0047] Take 50Kg of dandelion stems and leaves and 60Kg of dandelion root mixed raw materials, wash, crush, add 110Kg of water, and extract at 95°C for 60 minutes by percolation method to obtain 200Kg of dandelion extract mixture. Take 1Kg of carboxymethyl cellulose and 500g of pectin and mix; then take 80Kg of sucrose and 2Kg of honey and mix; use the 1.5Kg of beverage stabilizer mixture obtained above at a temperature of 68℃ and a stirring speed of 1200r / min. The 82Kg sweetener is microencapsulated until the microcapsules have a particle size of 0.5μm, and they are sieved twice with 200 mesh. Take the dandelion extract mixture and stabilizer sugar solution obtained above, add 1.7Kg of citric acid, 0.3Kg of sodium citrate, and mix, add 854.5Kg of purified water, stir and mix.

[0048] The mixed liquid obtained above was allowed to stand for 24 hours under a pressure of 20Mpa to obtain a homogeneous mixed liquid. Sterilize at 9

Example Embodiment

[0049] Example 3: Preparation of dandelion beverage

[0050] Take 12Kg of dandelion stems and leaves and 18Kg of dandelion root mixed raw materials, wash, break, add 30Kg of water, and extract at 100°C for 40 minutes by percolation method to obtain 50Kg of dandelion extract mixture. Take 1Kg of carboxymethyl cellulose and 500g of pectin and mix; then take 80Kg of sucrose and 2Kg of honey and mix; use the 1.5Kg of beverage stabilizer mixture obtained above at a temperature of 68℃ and a stirring speed of 1200r / min. The 82Kg sweetener is microencapsulated until the microcapsules have a particle size of 0.5μm, and they are sieved twice with 200 mesh. Take the dandelion extract mixture and stabilizer sugar solution obtained above, add 1.7Kg of citric acid, 0.3Kg of sodium citrate, and mix, add 714.5Kg of purified water, stir and mix.

[0051] The mixed liquid obtained above was allowed to stand for 24 hours under a pressure of 20Mpa to obtain a homogeneous mixed liquid. Sterilize at 10

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap