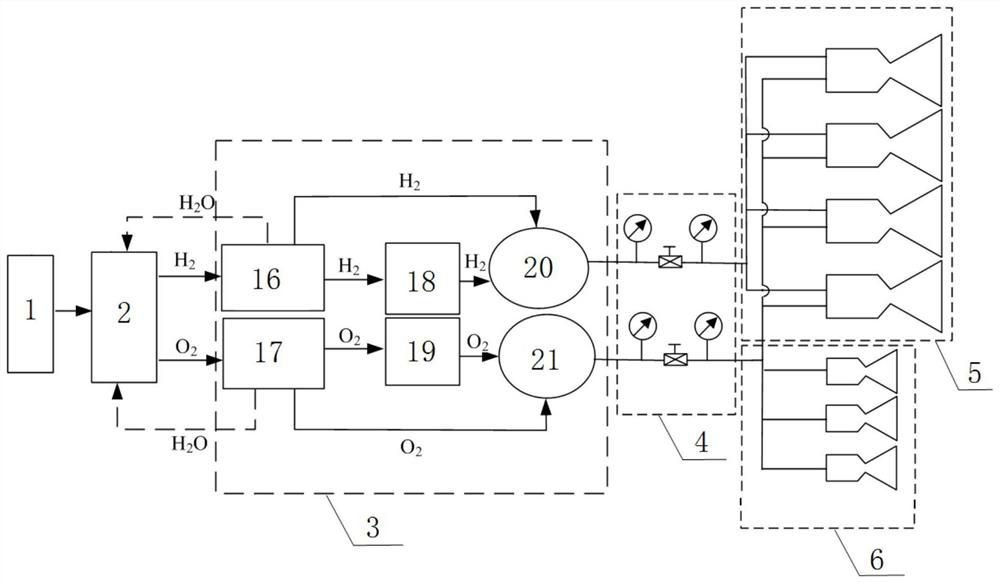

Space hybrid propulsion system based on technology of photocatalytic water splitting for hydrogen production

A technology of photo-splitting water for hydrogen production and space mixing, which is applied in jet propulsion, electrolysis process, electrolysis components, etc., can solve the problems of large size of solar panels, complex structure of propulsion system, and high power loss, etc., to simplify the system. Good structure, good stability, and the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

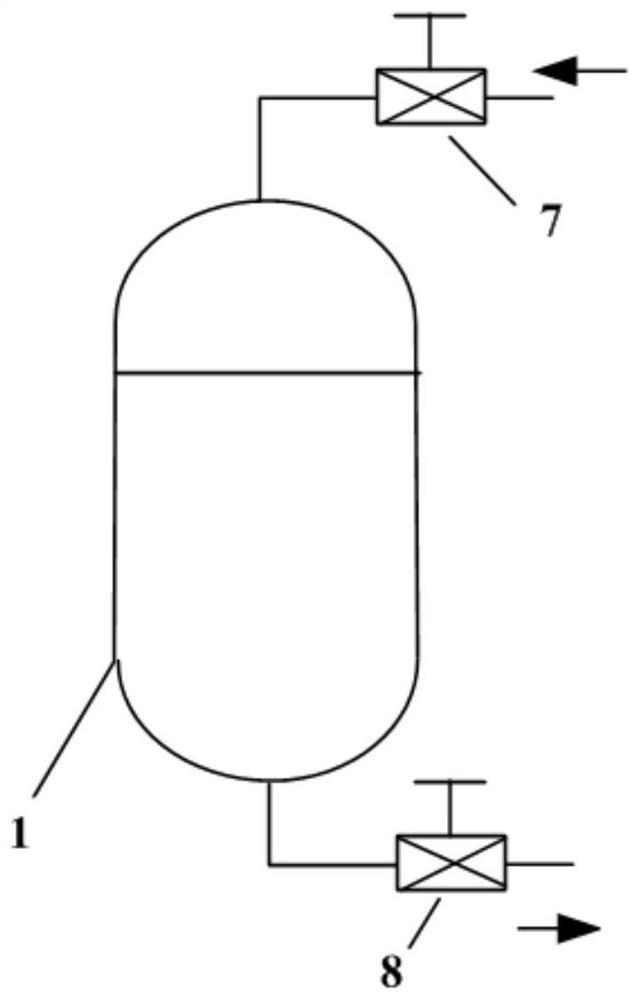

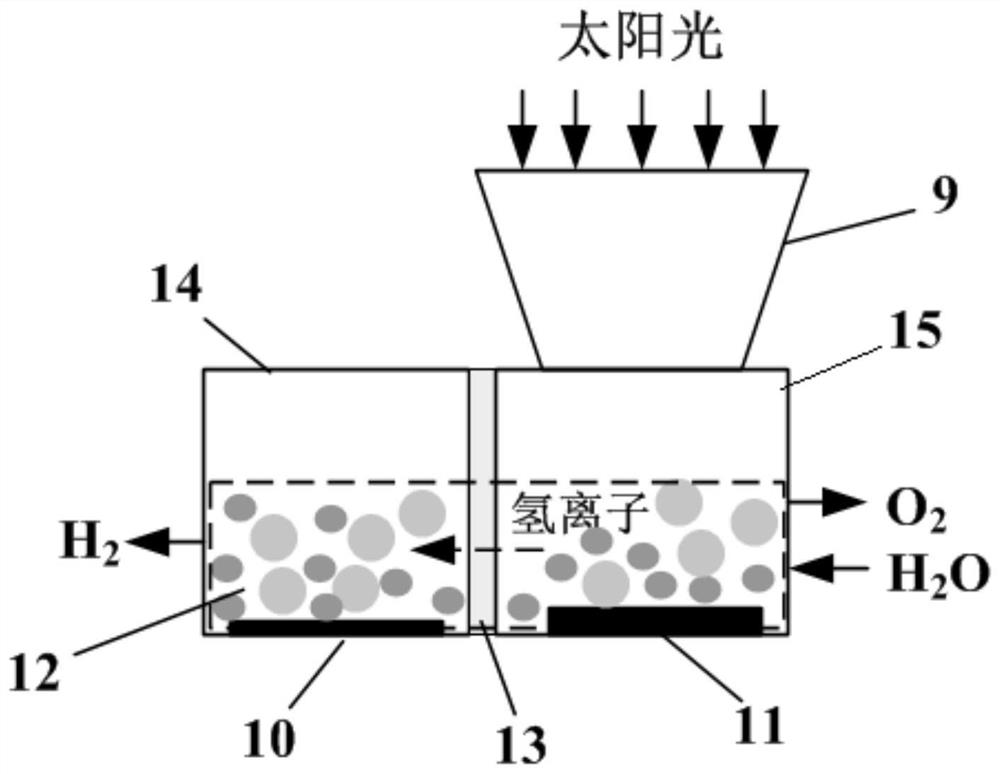

[0038]In order to make the objects, advantages and features of the present invention, the spatial hybrid propulsion system proposed by the present invention will be further described in detail below with reference to the accompanying drawings and the specific embodiments.

[0039]Photo hydrogen hydrogen hydrogen hydrogen production uses photocatalytic materials and solar energy to solve water into hydrogen and oxygen to solve a chemical technique of green production of solar storage and hydrogen production, mainly photocatalytic and photoelectric catalysis. The optoelectronic catalysis is advantageous with respect to photocatalysis, which can effectively separate and collect hydrogen and oxygen. In such a manner, the photoelectric catalysis is employed, and the catalyst is deposited on the conductive substrate, and the photode electrode is formed into a two-electrode system, and the two optic electrodes are immersed in the electrode. In the electrolyte, oxygen and hydrogen gas, hydrogen,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap