Ground-connected movable molten iron casting ladle dust collection device

A vacuum device, mobile technology, applied in the direction of metal processing equipment, casting equipment, manufacturing tools, etc., can solve the problems of unsafe equipment or staff, environmental pollution, capture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and given embodiments, but is not limited thereto.

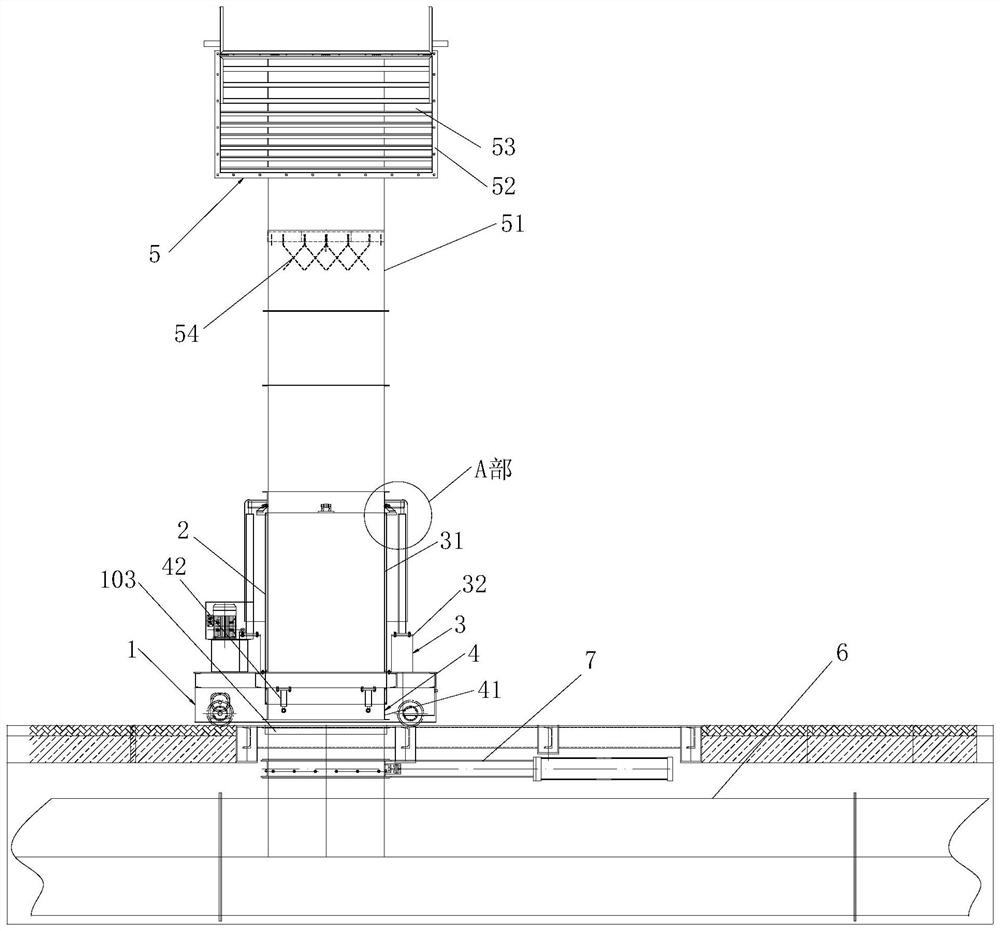

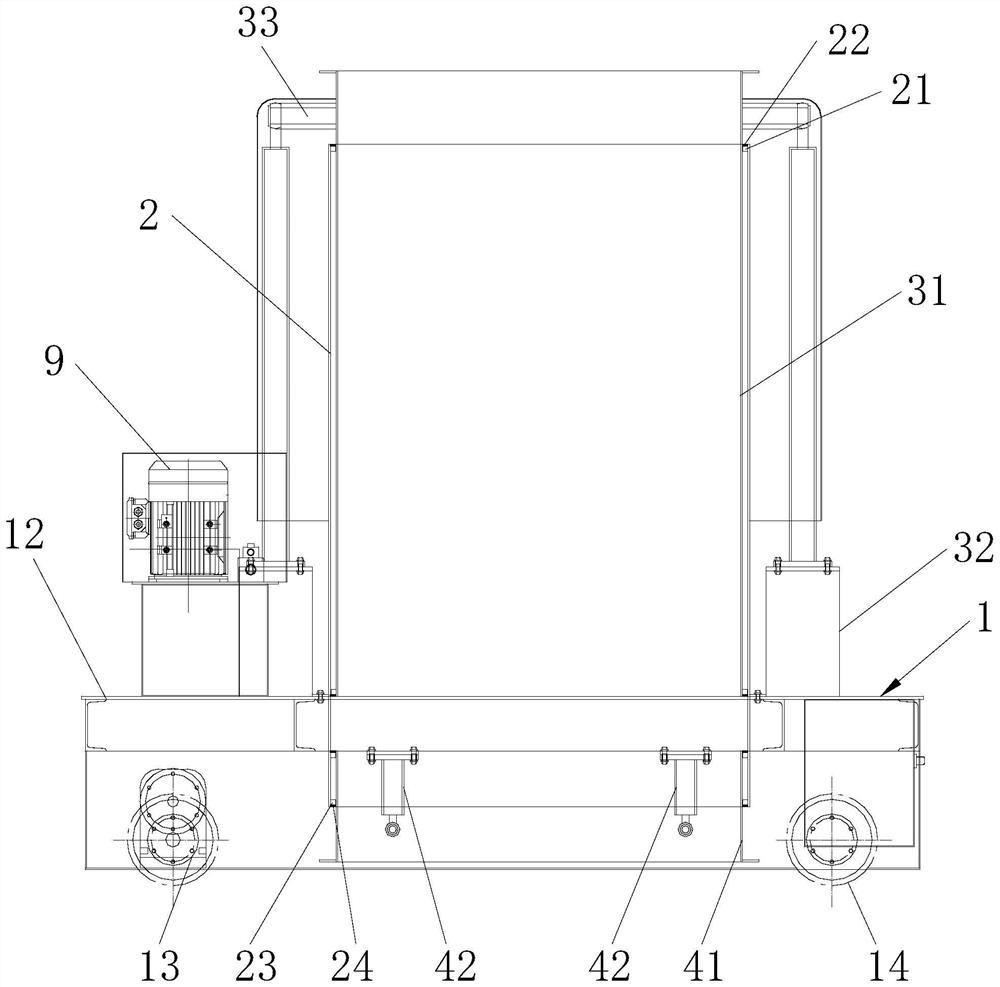

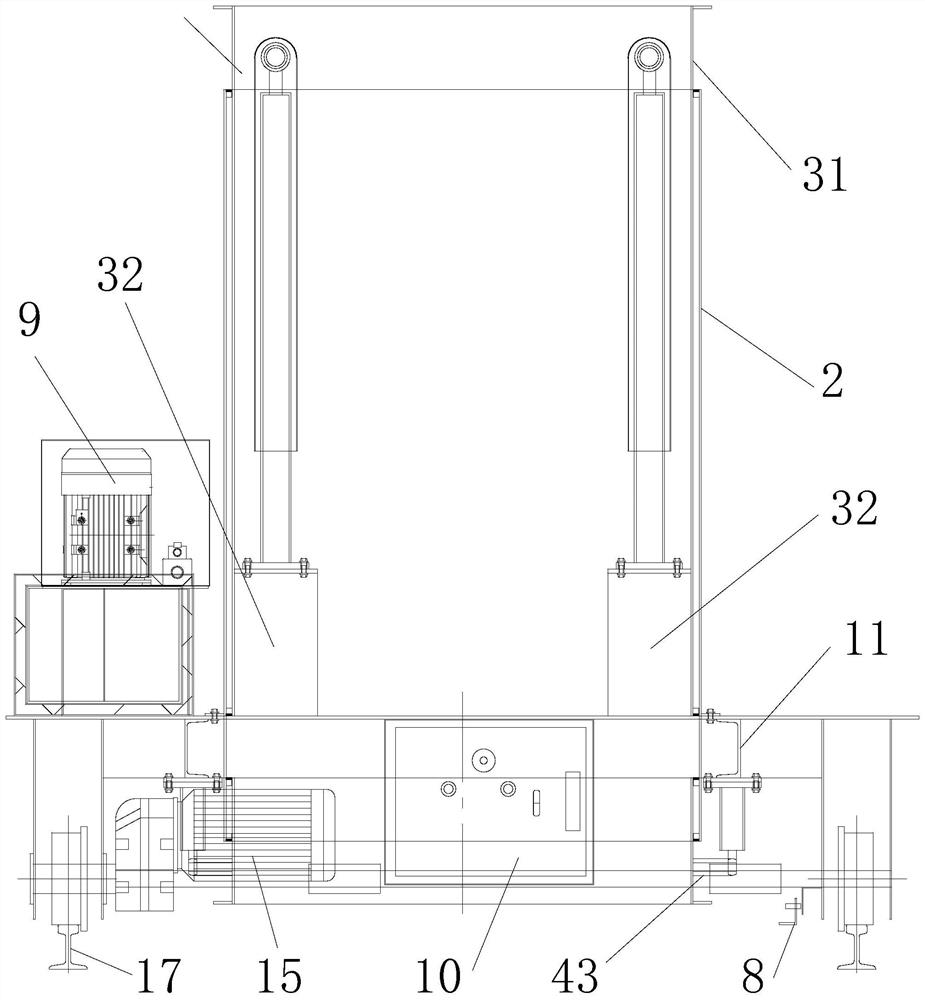

[0028] Such as figure 1 , 2 , 3, 4, 5, 6, and 7, a ground-connected mobile molten iron ladle vacuum device, including a mobile trolley 1, a sleeve 2, an upper sleeve telescopic mechanism 3, a lower sleeve telescopic mechanism 4 and suction The dust cover 5, and the smoke exhaust main pipe 6 pre-buried under the ground and connected to the dust removal equipment, the sleeve 2, the upper end sleeve telescopic mechanism 3 and the lower end sleeve telescopic mechanism 4 are all arranged on the mobile trolley 1, The dust collection cover 5 communicates with the telescoping mechanism 3 of the upper end sleeve,

[0029] The upper end sleeve telescopic mechanism 3 includes an upper end telescopic sleeve 31 and an upper lifting hydraulic cylinder 32, the sleeve 2 is fixed on the mobile trolley 1, and the upper part of the sleeve

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap