Drum screen

The technology of trommel screen and sieve barrel is applied to trommel screen. It can solve the problem of reducing the power consumption of the trommel screen, and achieve the effect of reducing power consumption and preventing slippage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

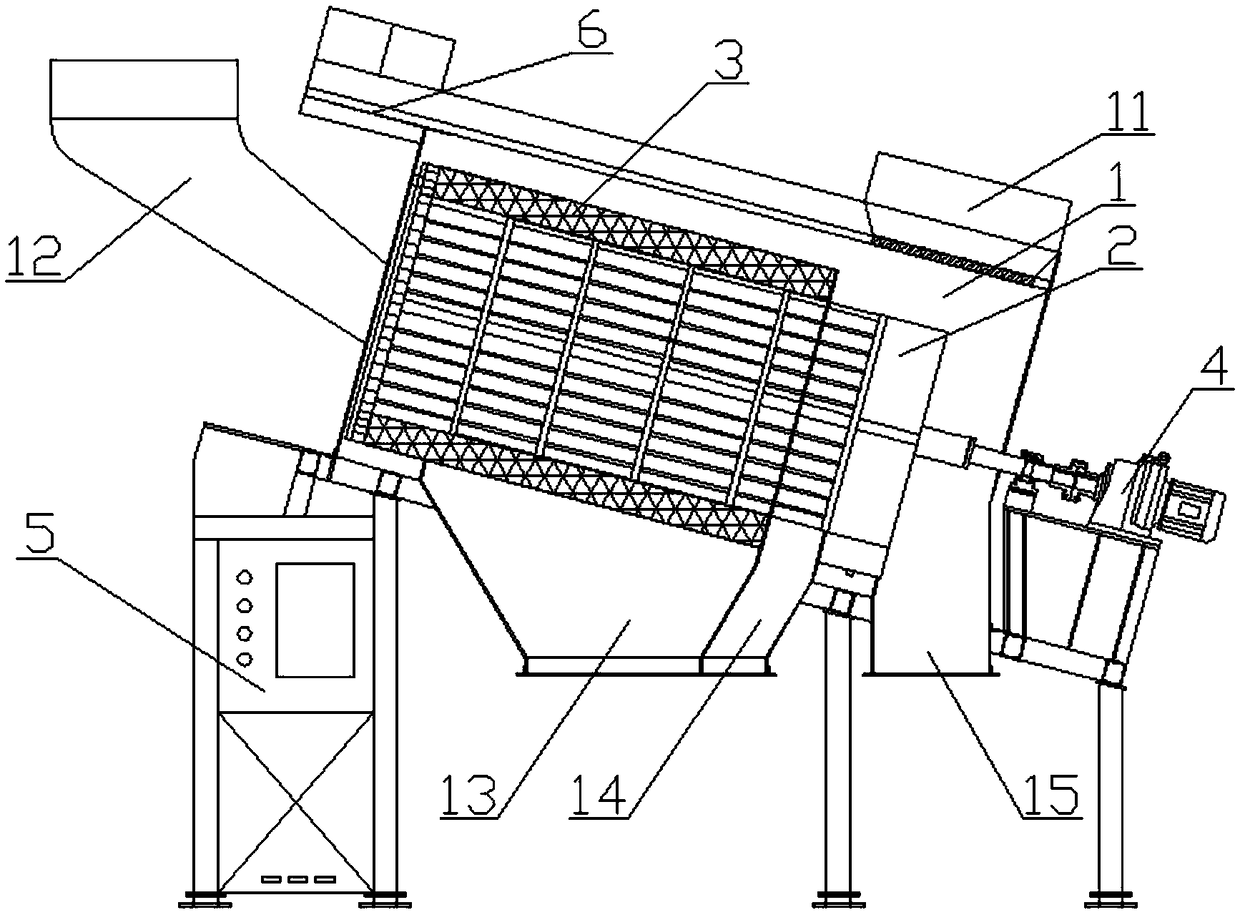

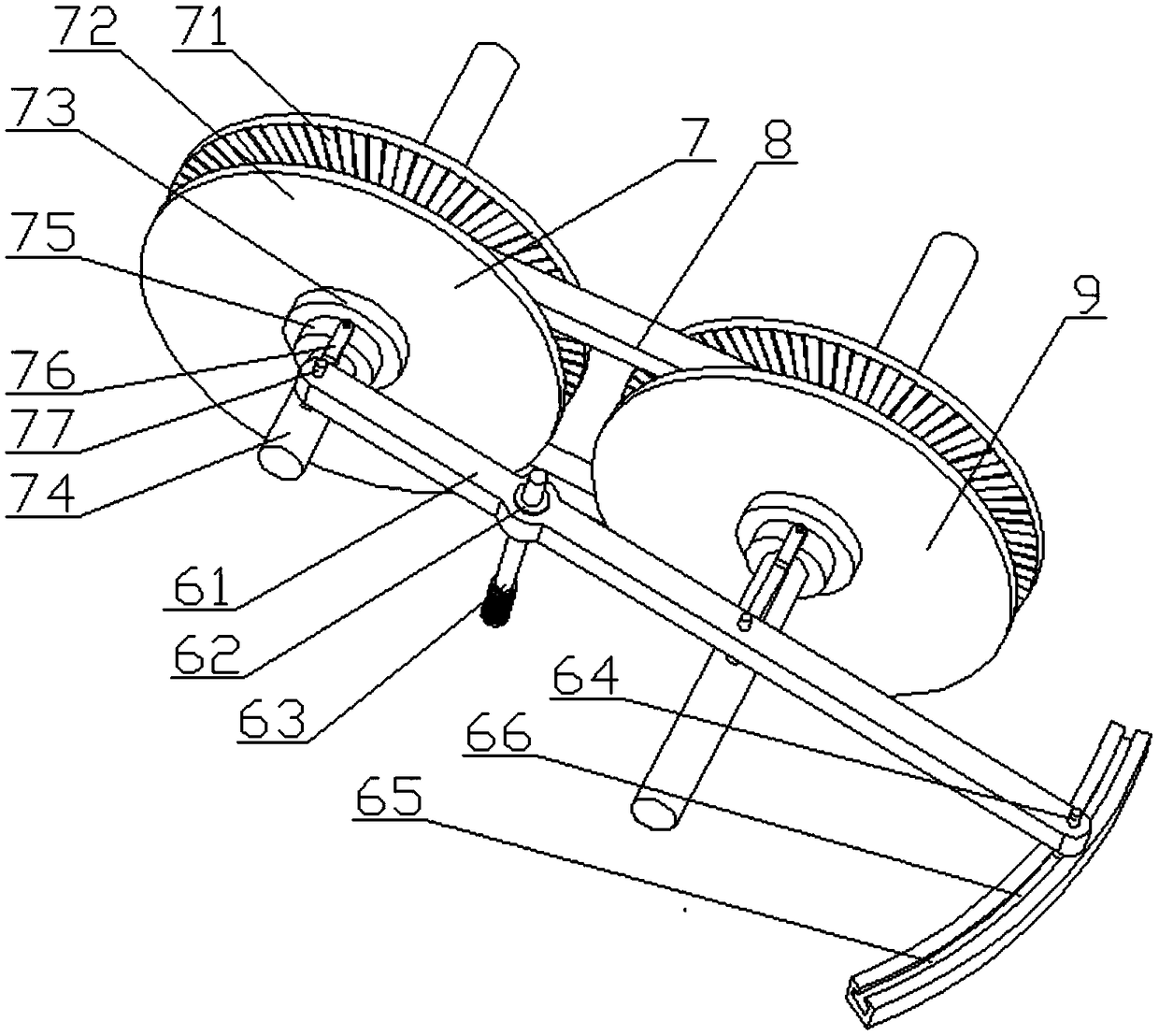

[0025] Such as Figure 1 to Figure 5 Shown; A drum sieve, including a shell 1 and a base, the bottom of the shell 1 is provided with a fine material outlet 13, a medium material outlet 14 and a coarse material outlet 15, and the top of the shell 1 is provided with a dust suction device 11 and A power switching mechanism 6, the two ends of the housing 1 are respectively connected with a power device 4 and a feed hopper 12, the housing 1 and the power device 4 are fixed on the base, and the side wall of the housing 1 is provided with a heating device; The casing 1 is provided with a coarse sieve barrel 2, a support bearing 31 and a side support bearing 22, the coarse sieve barrel 2 is provided with a fine sieve barrel 3, and the fine sieve barrel 3 is connected with the casing 1 through a support bearing 31, so The inner side of the fine screen barrel 3 away from the feed hopper 12 is provided with a side support bearing 22 connected to the coarse screen barrel 2, the inner side of

Embodiment 2

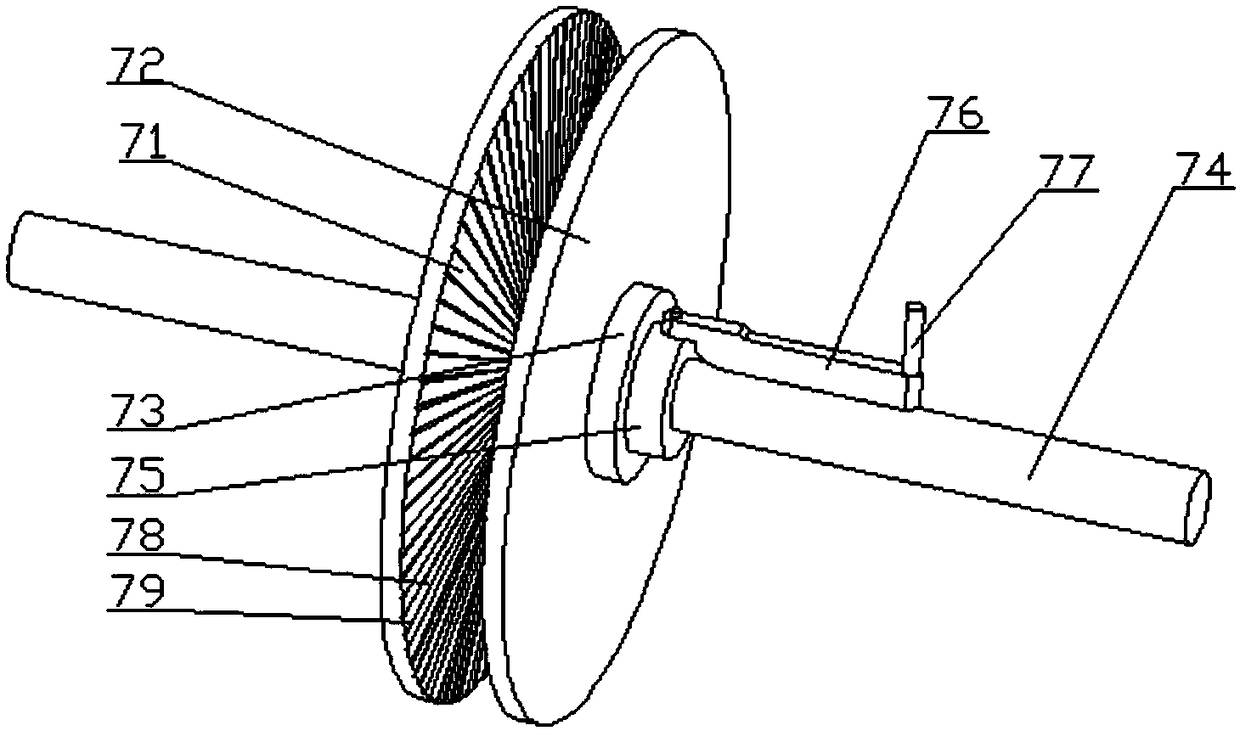

[0028]On the basis of embodiment 1, the adjustment slope 78 is provided with an anti-skid groove 79; the depth of the anti-skid groove 79 is at least 3mm; 78 forms an included angle A, the degree of the included angle A is 10 degrees to 35 degrees, and the degree of the included angle A is 20 degrees; it also includes an adjustment bearing 62, and the adjustment rod 61 is connected to the fixed rod through the adjustment bearing 62 63, the adjustment speed bar 65 is an oil cylinder, and also includes a controller 5, and the controller 5 is electrically connected to the oil cylinder, the heating device 4 and the dust collection device 11.

[0029] By adjusting the anti-skid groove 79 on the inclined surface 78, it is possible to prevent the transmission belt 8 from slipping, and the depth of the anti-skid groove 79 is set to be at least 3 mm deep, so that the frictional heat of the transmission belt 8 can be dissipated quickly when the transmission belt 8 is working, and the phenom

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap