Aerated shelf-stable dairy-based ready-to-drink beverage

a shelf-stable, ready-to-drink beverage technology, applied in milk preparation, other dairy technologies, cocoa, etc., can solve the problems of not satisfying watery beverages, thick beverages are not perceived as refreshing, and beverages have a very watery mouth-feel or thick texture, etc., to achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0126]Several coffee beverages were prepared by mixing liquid or powder milk or water, with sugar and other flavour ingredients, the other dairy based ingredients, the texture / stabilizer components (high acyl gellan gum, and / or pectin, locust bean gum, guar gum) and a buffering agent. The mixes had a pH of about 6.7. The mix was then pre-heated to 75° C., then sterilised at 143° C. during 5 seconds, then cooled to 75° C. prior to homogenisation under 150 / 50 bars. Then the liquid beverage was cooled to about 10° C., then aseptically filled into bottles. The bottles have a total volume of 8 oz (236 mL), and they are filled with 180 mL of coffee beverage. This leaves a headspace of about 60 mL, which corresponds to about 24 vol. %. The manufacture of the liquid coffee beverage was done under aseptic conditions, at atmospheric pressure.

example 2

1

[0127]A beverage was prepared by mixing 90 kg milk, 5 kg sugar, 0.5 kg of microcrystalline cellulose co-processed with carboxymethyl cellulose and carrageenan, 0.01 kg high acyl gellan gum under high agitation. Then 1 kg soluble coffee were added to the above slurry under agitation. Further, 0.1 kg of sodium hydroxide and remain water to obtain 100 kg total weight was added to the tank under agitation. The mixture was then pre-heated to about 75° C., sterilized at 143° C. for 5 seconds and then flash cooled to 75° C., homogenized using two step homogenization at 150 / 50 bars. The liquid beverage was cooled below 15° C., and then aseptically filled into 8 oz (about 236 mL) bottles having 30% headspace.

example 3

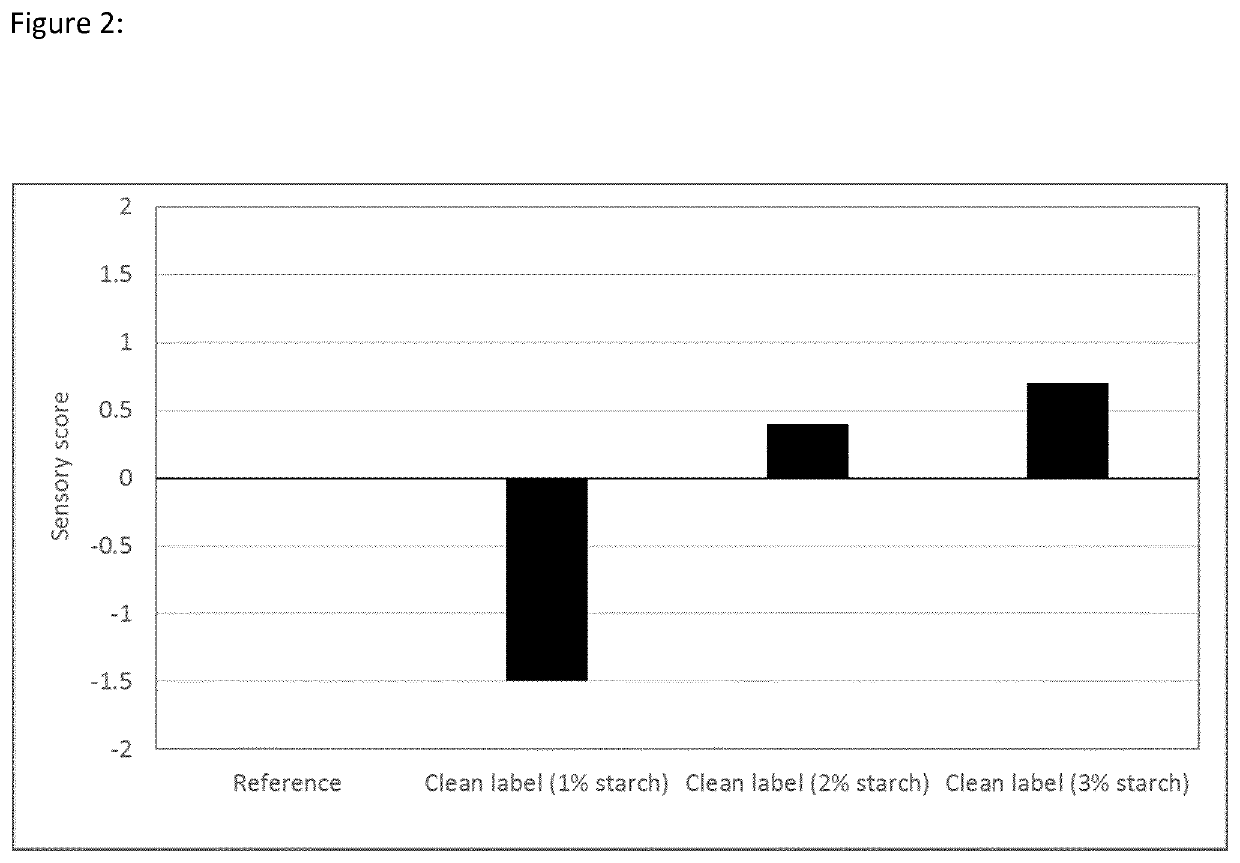

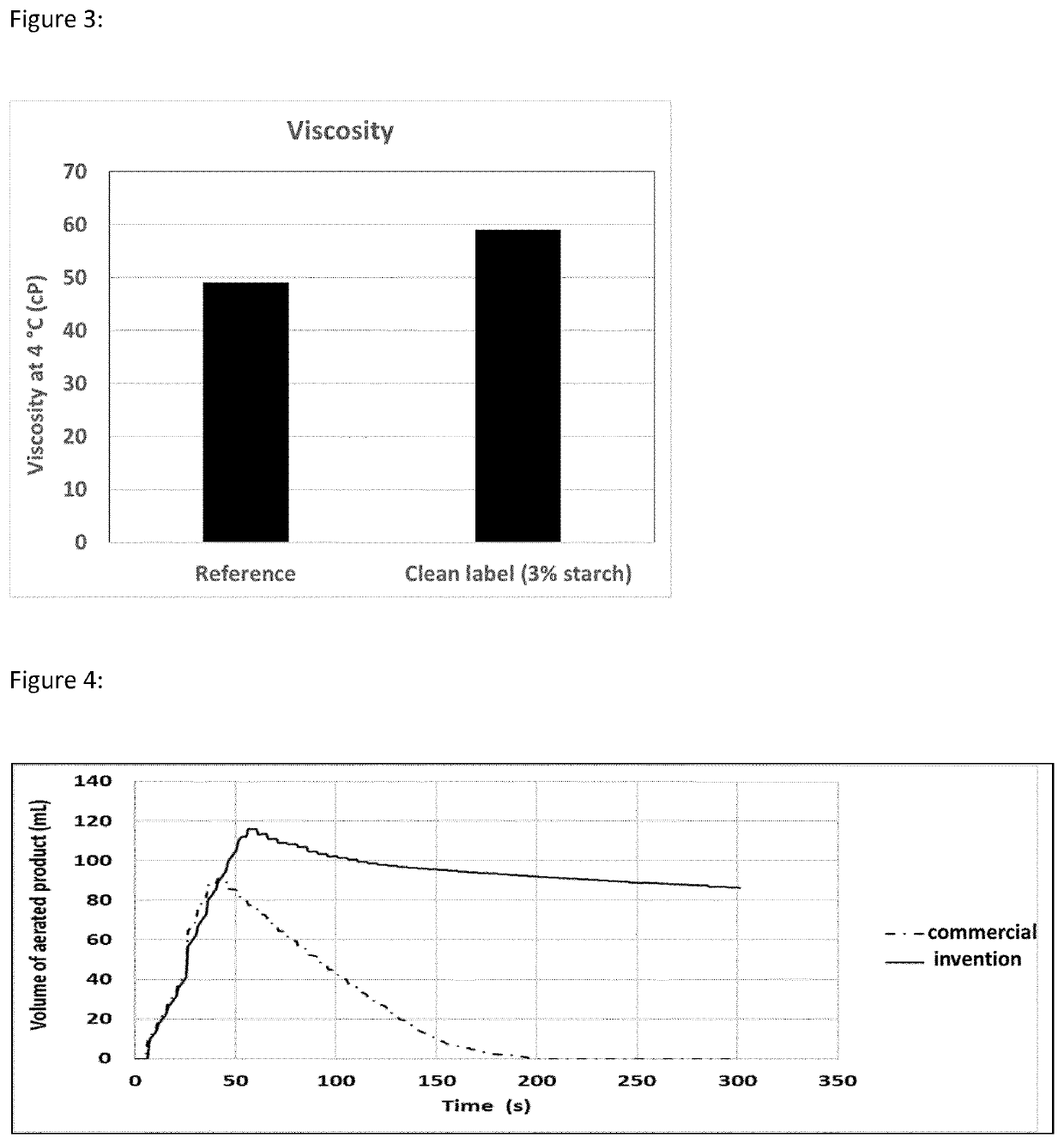

[0128]A beverage was prepared by mixing 90 kg milk, 5 kg sugar, 0.03 kg high acyl gellan gum under high agitation. Then 2 kg starch and 0.8 kg soluble coffee were added to the above slurry under agitation. Further, 0.08 kg of sodium bicarbonate and remain water to obtain 100 kg total weight was added to the tank under agitation. The mixture was then pre-heated to about 75° C., sterilized at 143° C. for 5 seconds and then flash cooled to 75° C., homogenized using two step homogenization at 150 / 50 bars. The liquid beverage was cooled below 15° C., and then aseptically filled into 8 oz (about 236 mL) bottles having 30% headspace.

[0129]Further, the product showed a good shelf life physical stability with no phase separation, sedimentation, or syneresis.

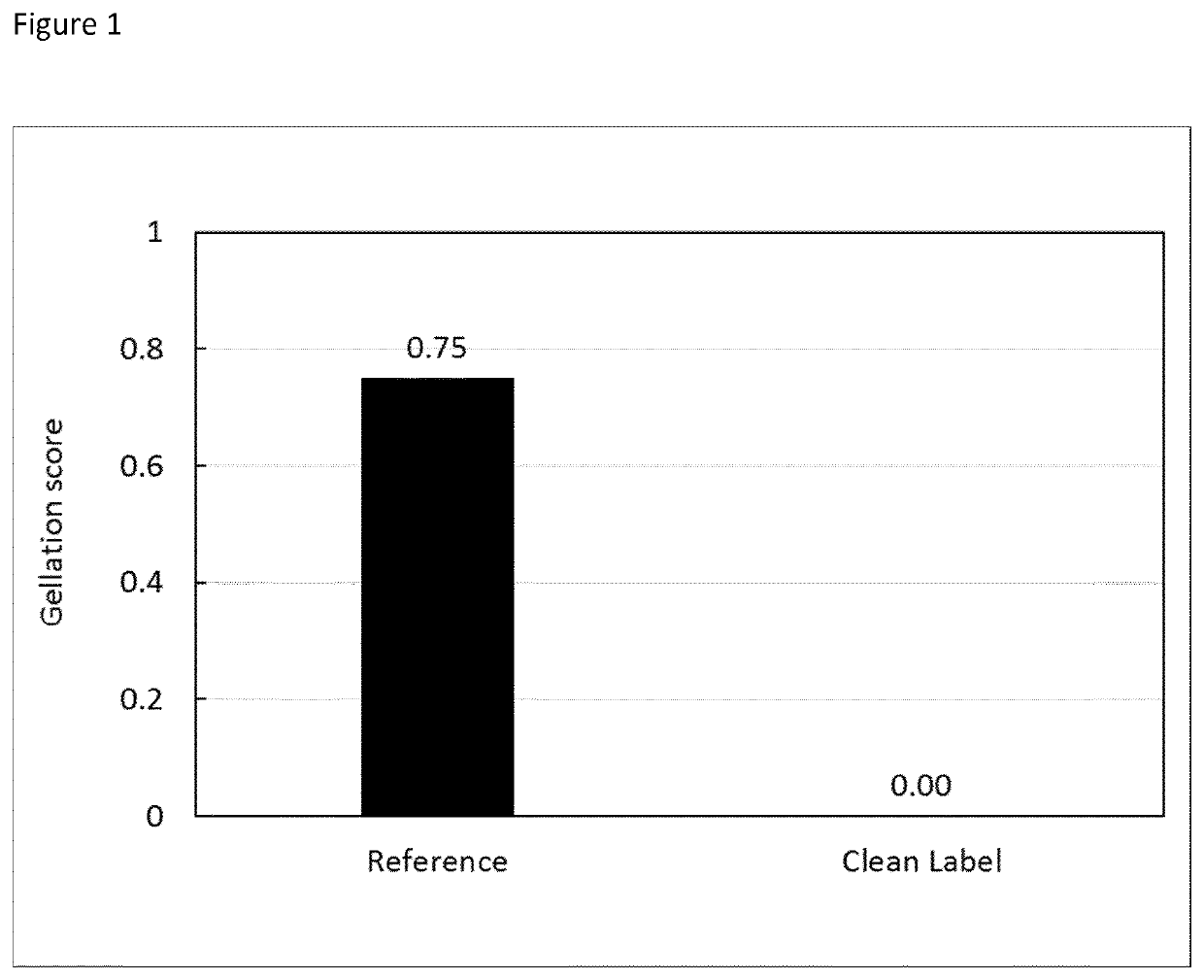

[0130]Unique indulgent, creamy texture / mouthfeel was obtained after product shaking. Product performance after shaking was compared with the reference and improvement in foamy mouthfeel and body / thickness was found.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap