High-thermal-conductivity polyimide film prepared from core-shell structure heat-conducting filler and preparation method of film

A polyimide film and thermally conductive filler technology, applied in the field of polyimide film, can solve the problems of no effective heat conduction channel, complex process cost, high cost, etc., to reduce interface scattering, reduce heat conduction loss, and reduce production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

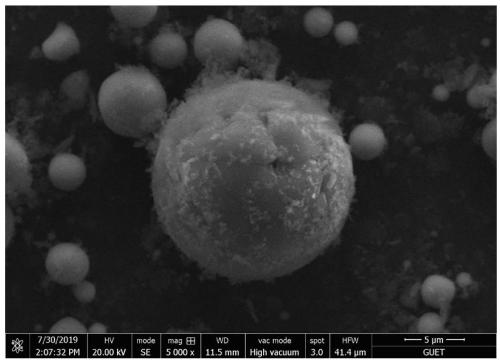

[0033] The core-shell thermal conductive filler is prepared, and the preparation method includes the following steps:

[0034] (1) Preparation of KH550 modified alumina: prepare 500ml of dispersion with anhydrous ethanol and deionized water in a volume ratio of 1:5, add glacial acetic acid dropwise to adjust the pH of the dispersion to 5, slowly add dropwise to the dispersion 4.3g KH550, mechanically stirred for 2h to hydrolyze KH550, then add 20g alumina, heat in a water bath at 60℃ for 2h, centrifuge and dry after reaction to obtain KH550 modified alumina;

[0035] (2) Preparation of modified boron nitride: Weigh 20g of boron nitride into the muffle furnace, set the temperature program, and calcinate in an air atmosphere at 900°C for 2h. Use deionized water as a dispersion to treat the calcined boron nitride After 2 hours of sonication, centrifugal drying, the modified boron nitride is prepared;

[0036] (3) Preparation of alumina coated with boron nitride: Weigh the modified boron n

Embodiment 1

[0038] A method for preparing a high thermal conductivity polyimide film includes the following steps:

[0039] (1) Add 3.15g of boron nitride to 82g of DMAC dispersion and ultrasonic for 2 hours, then add 8.615g of ODA, mechanically stir to dissolve the boron nitride, and prepare a reaction solvent containing boron nitride after ultrasonic stripping;

[0040] (2) Divide 9.385g PMDA into 50%, 20%, 20%, and 8% into the reaction solvent obtained in step (1) four times at 0.5h intervals. The remaining 2% PDMA adjusts the system viscosity to make The viscosity of the system reaches 50000 MPa·s, and a polyamic acid solution containing boron nitride is prepared;

[0041] (3) Add 3.15 g of thermally conductive filler of boron nitride coated alumina to the polyamic acid solution containing boron nitride prepared in the step, mechanically stir for about 3 hours, put it in a vacuum oven, and perform defoaming treatment at -1Mpa;

[0042] (4) Lay the film with the defoamed polyamic acid solution, p

Embodiment 2

[0045] A method for preparing a high thermal conductivity polyimide film includes the following steps:

[0046] (1) Add 4.2g of boron nitride to 82g of DMAC dispersion and ultrasonic for 2 hours, then add 8.615g of ODA, mechanically stir to dissolve the boron nitride, and prepare a reaction solvent containing boron nitride after ultrasonic stripping;

[0047] (2) Divide 9.385g PMDA into 50%, 20%, 20%, and 8% into the reaction solvent obtained in step (1) four times at 0.5h intervals. The remaining 2% PDMA adjusts the system viscosity to make The viscosity of the system reaches 50000 MPa·s, and a polyamic acid solution containing boron nitride is prepared;

[0048] (3) Add 2.1 g of the thermally conductive filler of boron nitride coated alumina to the polyamic acid solution containing boron nitride prepared in the step, mechanically stir for about 3 hours, put it in a vacuum oven, and perform defoaming treatment at -1Mpa;

[0049] (4) Lay the film with the defoamed polyamic acid solution,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap