Nickel-carbon nanotube composite material and preparation method thereof

A composite material, carbon nanotube technology, applied in nickel compounds, nanotechnology, carbon compounds, etc., can solve the problems of limited application, curved carbon nanotubes, unsatisfactory quality, etc., to achieve high application value, saturation magnetization High and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] (2) Preparation method of nickel-carbon nanotube composite material

[0064] The invention provides a method for preparing a nickel-carbon nanotube composite material, which is characterized in that a mixed gas of hydrogen and an inert gas is used as a carrier gas, flower-shaped nickel-aluminum hydrotalcite is used as a catalyst precursor, and heavy oil is used as a carbon source , preparing the composite material by vapor deposition method.

[0065] According to the present invention, the preparation method of the composite material further comprises:

[0066] (1) The flower-shaped nickel-aluminum hydrotalcite and the heavy oil are respectively placed in the high-temperature zone and the low-temperature zone of the vapor deposition furnace; (2) the carrier gas is blown from the low-temperature zone where the heavy oil is placed to the high-temperature zone where the flower-shaped nickel-aluminum hydrotalcite is placed. Perform vapor deposition in the high temperature zon

Embodiment 1

[0082] (1) Preparation of flower-shaped nickel-aluminum hydrotalcite

[0083] Take Ni(NO 3 ) 2 ·6H 2 O (0.17448g), Al (NO 3 ) 3 9H 2 O (0.075026g), hexamethylenetetramine (0.14019g) and NH 4 F (0.029632g) was added to a polytetrafluoroethylene reactor, and 40mL of deionized water was added, placed in an oven, and subjected to a hydrothermal reaction at 100°C for 12 hours. After the reaction, the solution taken out was centrifuged in a centrifuge at 9000 rpm, washed, Finally, take the precipitate in the centrifuge tube, dry it in an oven at 50°C, and grind it to obtain the product.

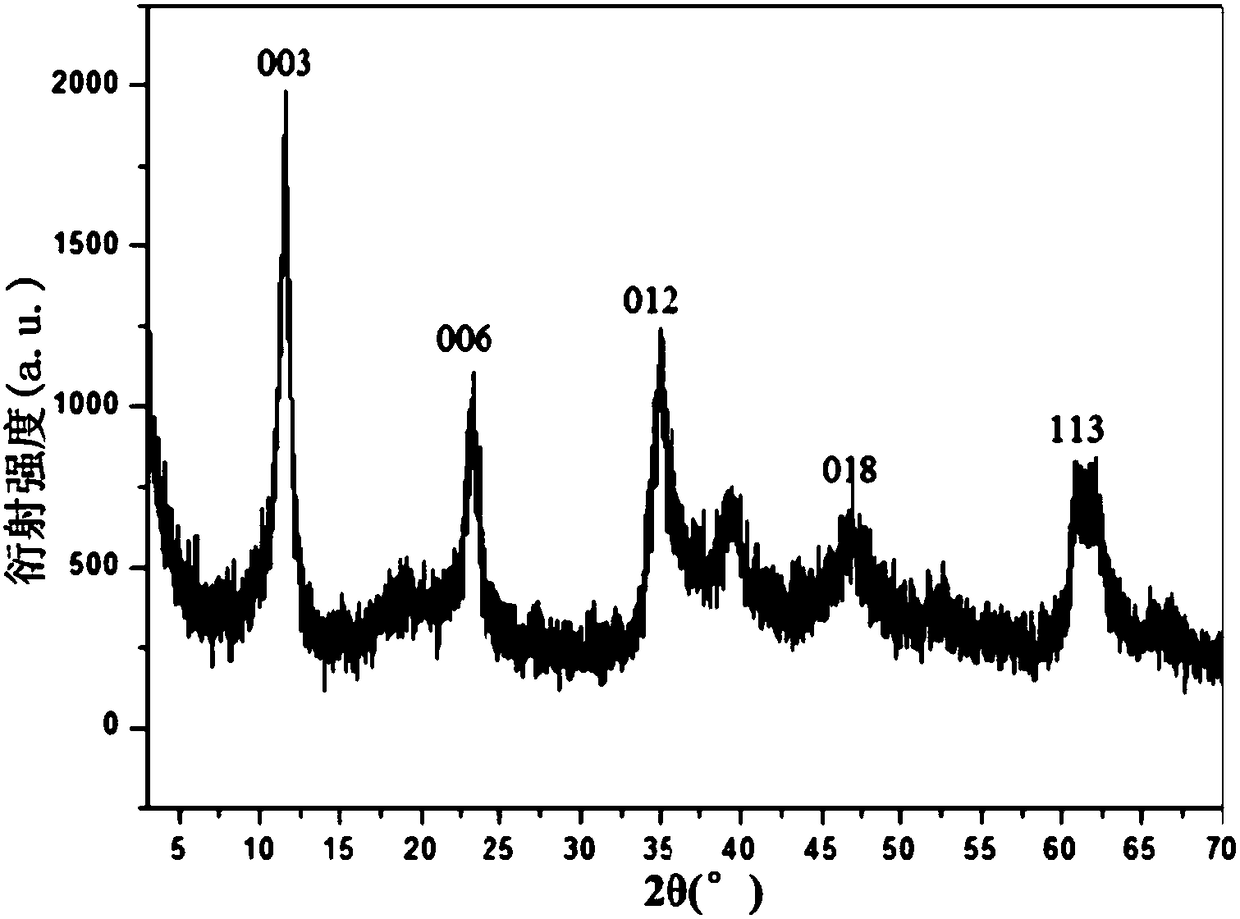

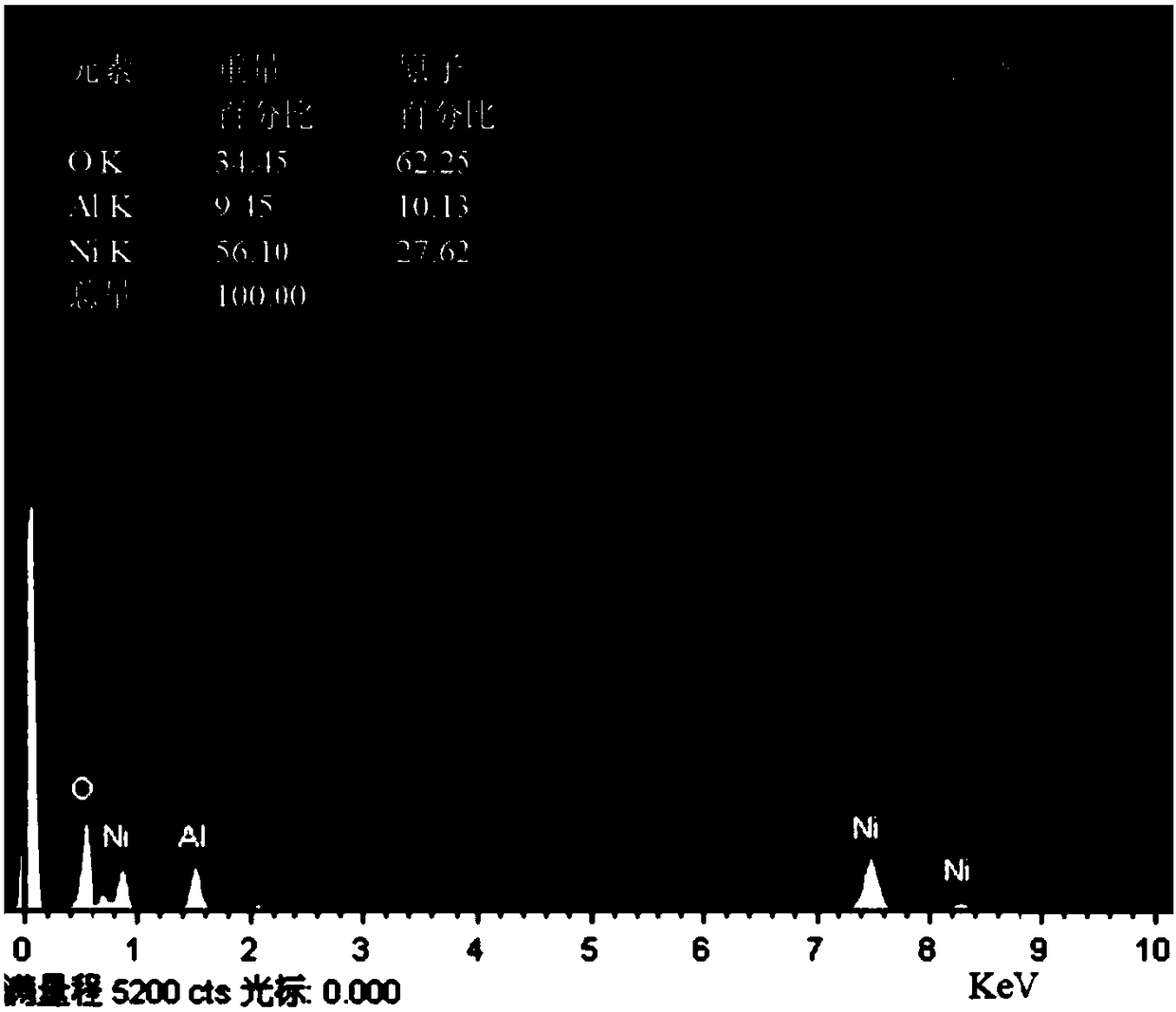

[0084] figure 1 It can be seen that the product obtained in (1) is flower-like dispersed globules, the thickness of each nanosheet is about 10nm, and there is non-stacking growth between sheets. figure 2 Visible, the product obtained in (1) has the standard diffraction peak of hydrotalcite, and does not have impurity to exist. image 3 It can be seen that the product obtained in (1) contains

Embodiment 2

[0097] (1) Preparation of flower-shaped nickel-aluminum hydrotalcite

[0098] Take Ni(NO 3 ) 2 ·6H 2 O(0.23264g), Al(NO 3 ) 3 9H 2 O (0.12004g), hexamethylenetetramine (0.194736g) and NH 4 F (0.04148g) was added to a polytetrafluoroethylene reactor, and 37mL of deionized water was added, placed in an oven, and subjected to a hydrothermal reaction at 105°C for 10 hours. After the reaction, the solution taken out was centrifuged in a centrifuge at 8000 rpm, and washed. Finally, take the precipitate in the centrifuge tube, dry it in an oven at 60°C, and grind it to obtain the product.

[0099] (2) Preparation of nickel-carbon nanotube composites

[0100] With hydrogen-argon mixed gas as carrier gas, wherein the volume ratio of hydrogen and argon is 1:9, with the flower-shaped hydrotalcite obtained in (1) as catalyst precursor, heavy oil as carbon source, nickel-aluminum hydrotalcite (30mg ) and heavy oil (Kuwait vacuum residue 0.5g, properties see Table 1) are loaded into a

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap