Preparation method and application of water-soluble carbon fiber sizing agent

A carbon fiber and water-soluble technology, which is applied in the field of preparation of water-soluble carbon fiber sizing agent, can solve the problems of unsatisfactory hydrophilicity and dispersibility of carbon fiber, unfavorable dispersibility of carbon fiber, and low surface energy of carbon fiber, so as to facilitate the preparation of sizing and sizing , Improve the effect of hydrophilicity and good smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

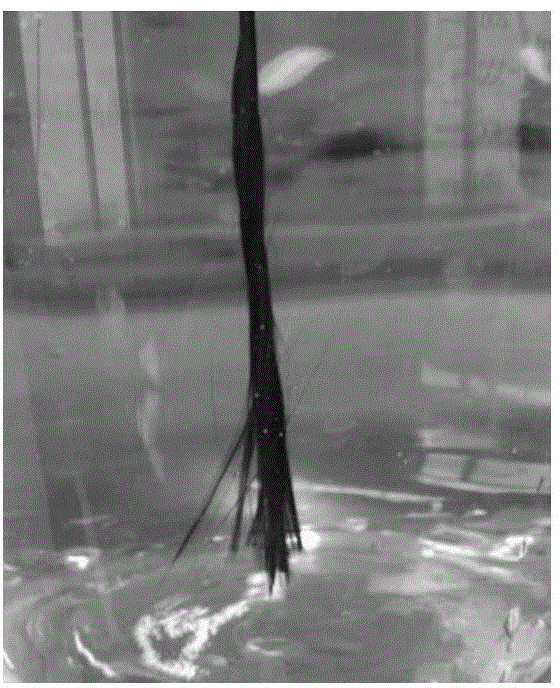

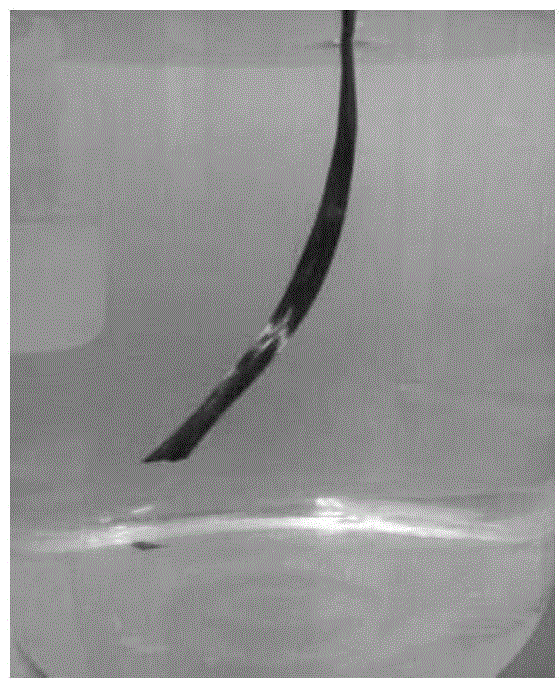

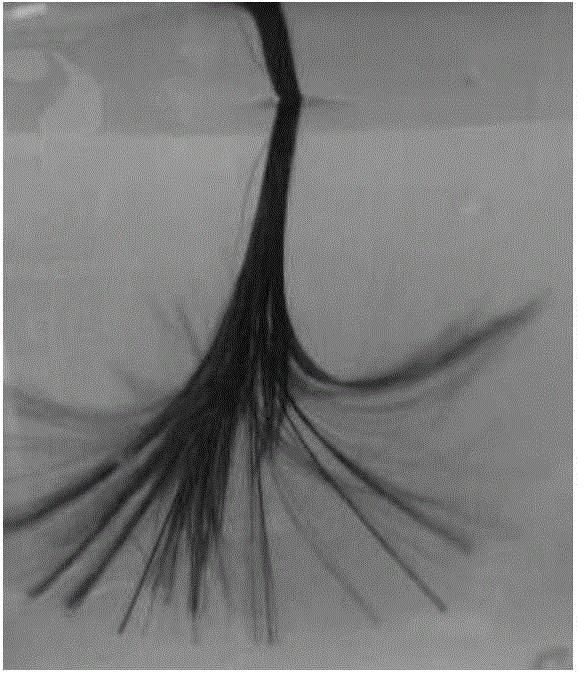

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: a kind of carbon fiber sizing agent, it is made by the mixture of polyvinyl alcohol and polyquaternium salt, carboxymethyl cellulose, emulsifier of A-110 specification and ethanol aqueous solution, and the weight ratio is 8:0.7 :0.6:90. When making, first add the mixture of 8 parts of polyvinyl alcohol and polyquaternary ammonium salt to 40 parts of ethanol aqueous solution at 60-70 °C, stir to dissolve it completely, then add 50 parts of remaining ethanol aqueous solution, and adjust the temperature to 30-30 °C. 50°C; Add 0.7 parts of carboxymethyl cellulose and 0.6 parts of A-110 emulsifier to the above solution, stir and dissolve to form an integrated solution, and obtain a water-soluble carbon fiber sizing agent.

[0020] The weight fraction of the carbon fiber after sizing with this sizing agent is 1.9%; through the contact angle test, the contact angle between the carbon fiber and water after sizing is reduced by 21% compared with that before

specific Embodiment approach 2

[0021] Specific embodiment two: a kind of carbon fiber sizing agent, it is made by the mixture of polyvinylpyrrolidone and polyacrylic acid and polymaleic anhydride, the emulsifier of hydroxyethyl cellulose, A-110 specification and A-115 specification, aqueous ethanol system into, the weight ratio is 5:0.1:0.2:95. When making it, add 5 parts of polyvinylpyrrolidone, polyacrylic acid and polymaleic anhydride to 45 parts of ethanol aqueous solution at 70-80°C, stir to dissolve it completely, then add 50 parts of remaining ethanol aqueous solution to adjust temperature to 30-50°C; then add 0.1 part of hydroxyethyl cellulose and 0.2 parts of emulsifiers of A-110 and A-115 specifications to the above solution, stir and dissolve to form a unified solution, and obtain a water-soluble Permanent carbon fiber sizing agent.

[0022] The weight fraction of the carbon fiber after sizing with this sizing agent is 1.5%; through the contact angle test, the contact angle between the carbon fiber

specific Embodiment approach 3

[0023] Specific embodiment three: a kind of carbon fiber sizing agent, it is made of the mixture of polyvinylpyrrolidone and polyvinyl alcohol, the mixture of methyl cellulose and sodium polyacrylate, the emulsifier of A-105 specification and A-115 specification, deionized Made of water, the weight ratio is 7:0.1:0.2:90. When making it, first add the mixture of 7 parts of polyvinylpyrrolidone and polyvinyl alcohol to 90 parts of deionized water at 80-100 ° C, stir to dissolve it completely, and then add 0.1 parts of methyl cellulose and The mixture of sodium polyacrylate and 0.2 parts of emulsifiers of A-105 and A-115 specifications are added to the above solution, stirred and dissolved to form an integrated solution, and a water-soluble carbon fiber sizing agent is obtained.

[0024] The weight fraction of the carbon fiber after sizing with this sizing agent is 1.77%; through the contact angle test, the contact angle between the carbon fiber and water after sizing is reduced by

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap