Positive electrode material and preparation method and application thereof

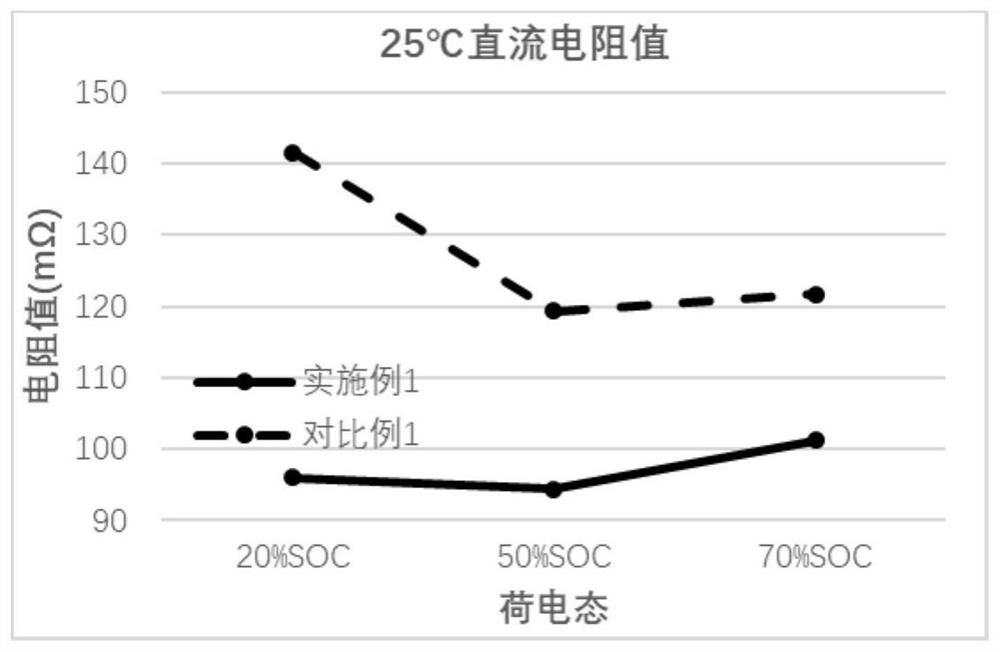

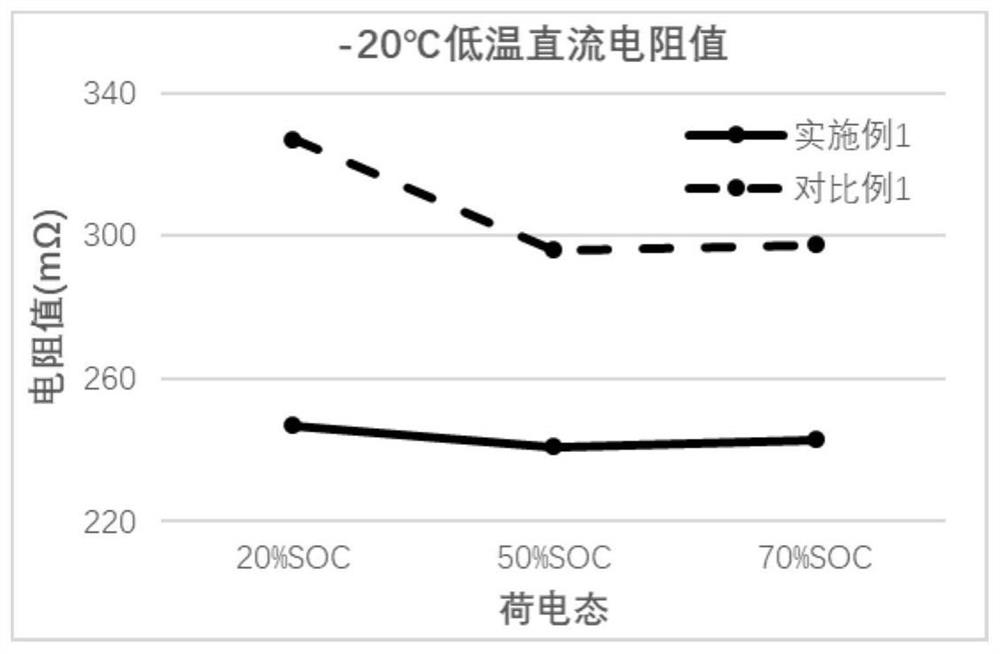

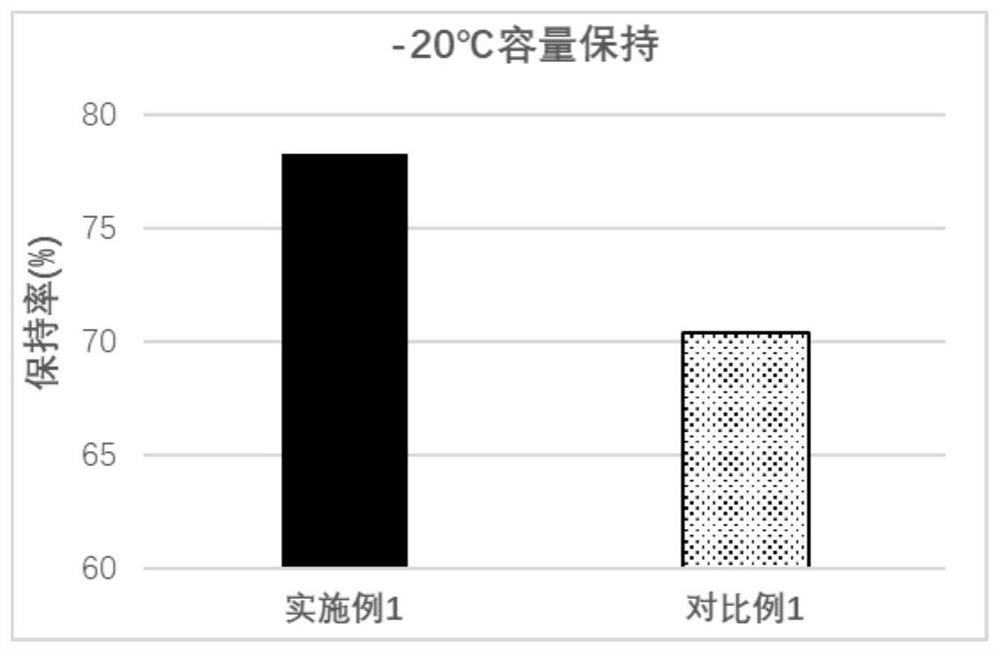

A positive electrode material and positive electrode sheet technology, applied in the field of positive electrode materials and their preparation, can solve the problems of low ionic and electronic conductivity of materials, limit the development of lithium-ion batteries, and poor conductivity of the coating layer, and achieve good electrochemical performance, Improve the interface bonding effect and reduce the effect of battery internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] Yet another embodiment provides a method for preparing the positive electrode material, the preparation method comprising:

[0065] mixing the positive electrode material core with the first cobalt source, and performing the first sintering; and

[0066] The first sintered product is mixed with the second cobalt source, and the second sintering is carried out to obtain the positive electrode material.

[0067] In some embodiments, the ratio of the total mass of the first cobalt source and the second cobalt source to the mass of the positive electrode material core is m:(100-m), wherein m is 0.01 to 2, preferably 1.4 to 1.6.

[0068] In some embodiments, the mass ratio of the first cobalt source and the second cobalt source is n:(100-n), wherein n is 10-30, preferably 24-26.

[0069] In some embodiments, the first cobalt source includes CoOOH, CoCO 3 , Co(NO 3 ) 2 and Co(NO 3 ) 4 Any one or a combination of at least two, preferably CoOOH.

[0070] In some embodiment

Embodiment 1

[0077] This embodiment provides a positive electrode material, the positive electrode material includes single crystal LiNi 0.53 co 0.11 mn 0.36 o 2 Inner core, coated with single crystal LiNi in planar form 0.53 co 0.11 mn 0.36 o 2The first cladding layer on the surface of the inner core and the second cladding layer coated on the surface of the first cladding layer in the form of dots, the first cladding layer includes amorphous cobalt oxide, and the second cladding layer The layer includes crystalline cobalt oxide, the ratio of the mass of the core of the positive electrode material in the positive electrode material to the total mass of the first cladding layer and the second cladding layer is 98.54:1.46, and the first cladding layer and the second cladding layer The mass ratio of the cladding is 21:79.

[0078] This embodiment also provides a preparation method for the above positive electrode material, the preparation method comprising the following steps:

[0079]

Embodiment 2

[0083] This embodiment provides a positive electrode material, which includes secondary spherical LiNi 0.53 co 0.11 mn 0.36 o 2 Inner core, covered in quadratic spherical LiNi in planar form 0.53 co 0.11 mn 0.36 o 2 The first cladding layer on the surface of the inner core and the second cladding layer coated on the surface of the first cladding layer in the form of dots, the first cladding layer includes amorphous cobalt oxide, and the second cladding layer The layer includes crystalline cobalt oxide, the ratio of the mass of the core of the positive electrode material in the positive electrode material to the total mass of the first cladding layer and the second cladding layer is 99.25:0.75, and the first cladding layer and the second cladding layer The mass ratio of the coating is 12.6:87.4.

[0084] This embodiment also provides a preparation method for the above positive electrode material, the preparation method comprising the following steps:

[0085] (1) CoCO 3 a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap