Automatic screw rod feeding device

An automatic feeding and screw technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of poor screw effect and poor versatility, and achieve the effects of reducing labor intensity, accurate and reliable material distribution, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0039] Embodiments of the present invention will be described in detail below in conjunction with specific drawings. For ease of description, the drawings only show relevant parts of the present application.

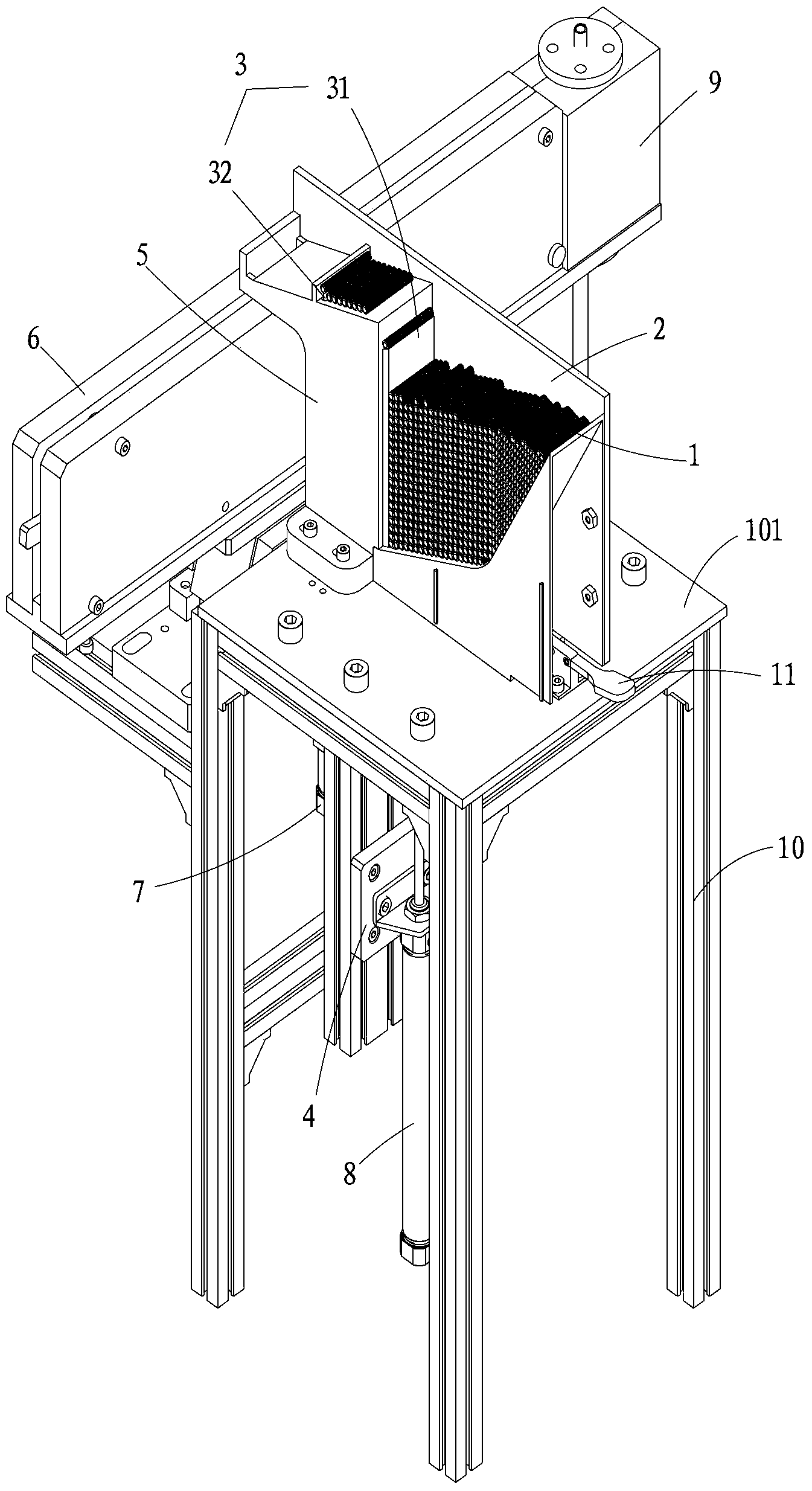

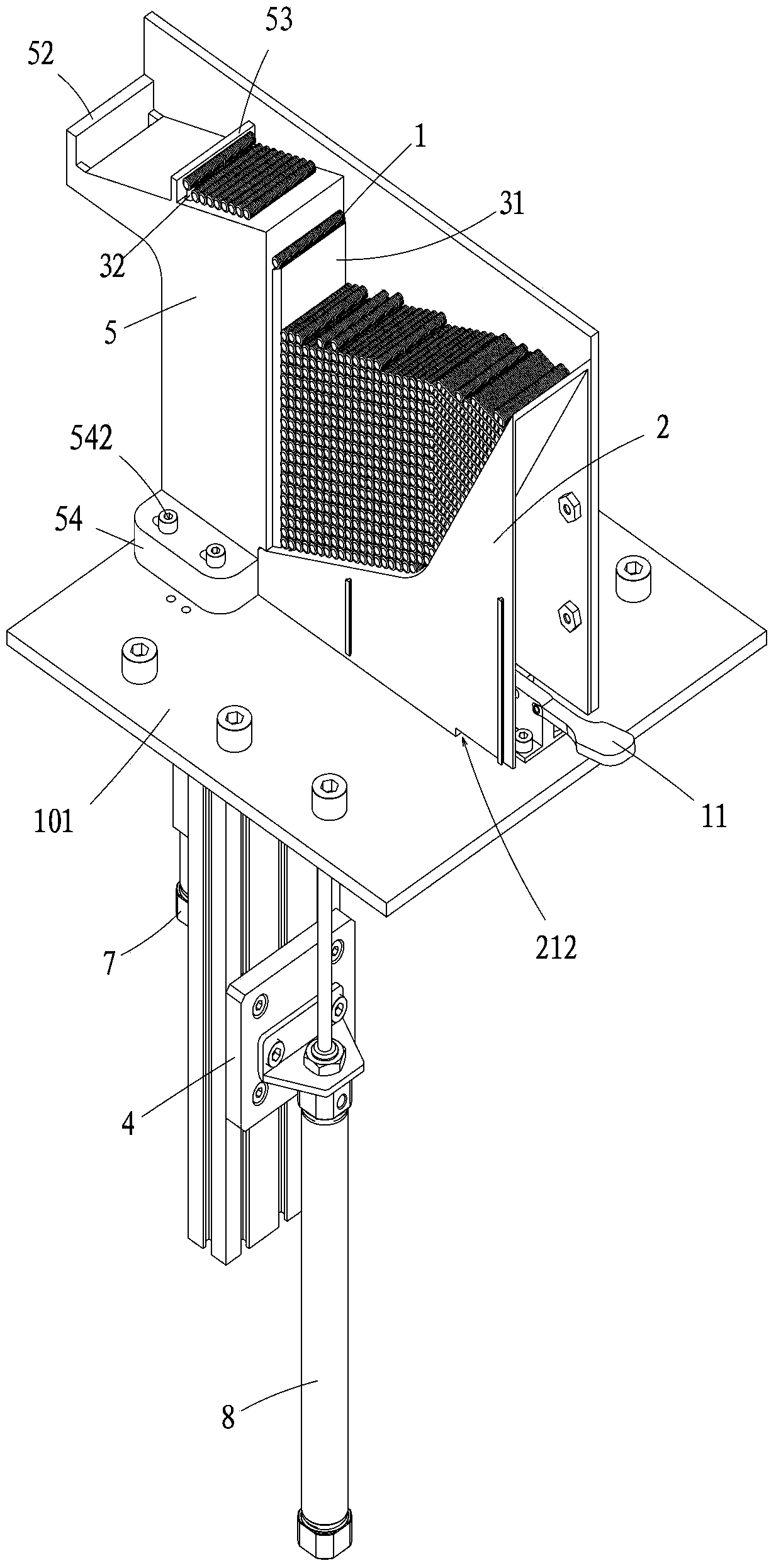

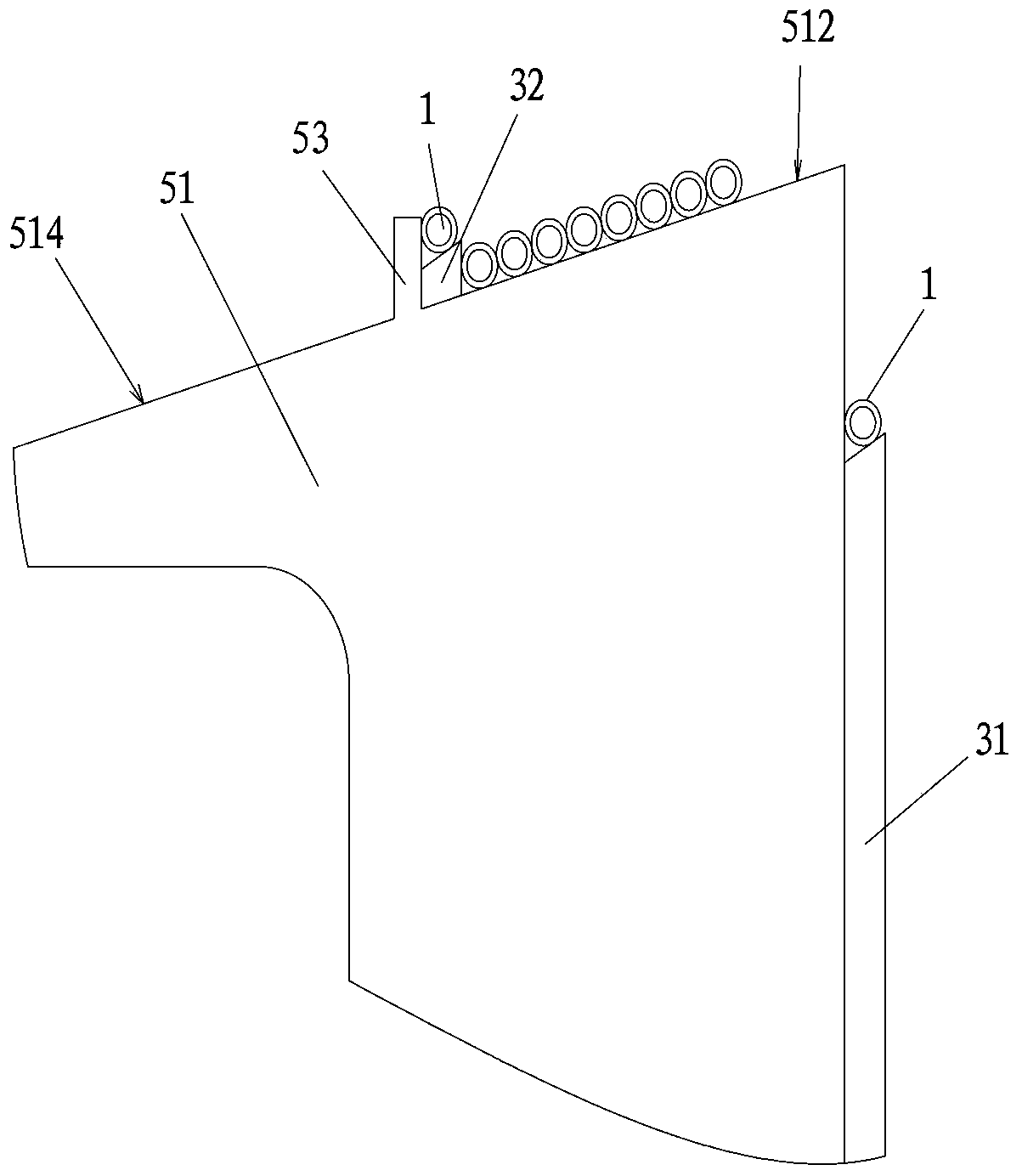

[0040] see Figure 1-9 , the invention provides an embodiment of a screw automatic feeding device, which includes:

[0041] Frame 10, as the carrier of each moving part and each connecting fixed part, it includes a frame body composed of four supporting feet 102 and a workbench 101 arranged horizontally on the top of the frame body;

[0042] At least one quick-change material box 2 is arrange

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap