Adhesive tape cutting machine

A cutting machine and tape technology, which is applied in the directions of sending objects, thin material handling, transportation and packaging, etc., can solve the problems of difficult tape extraction and short tape extension length, and achieve good use effect, improve efficiency and improve practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

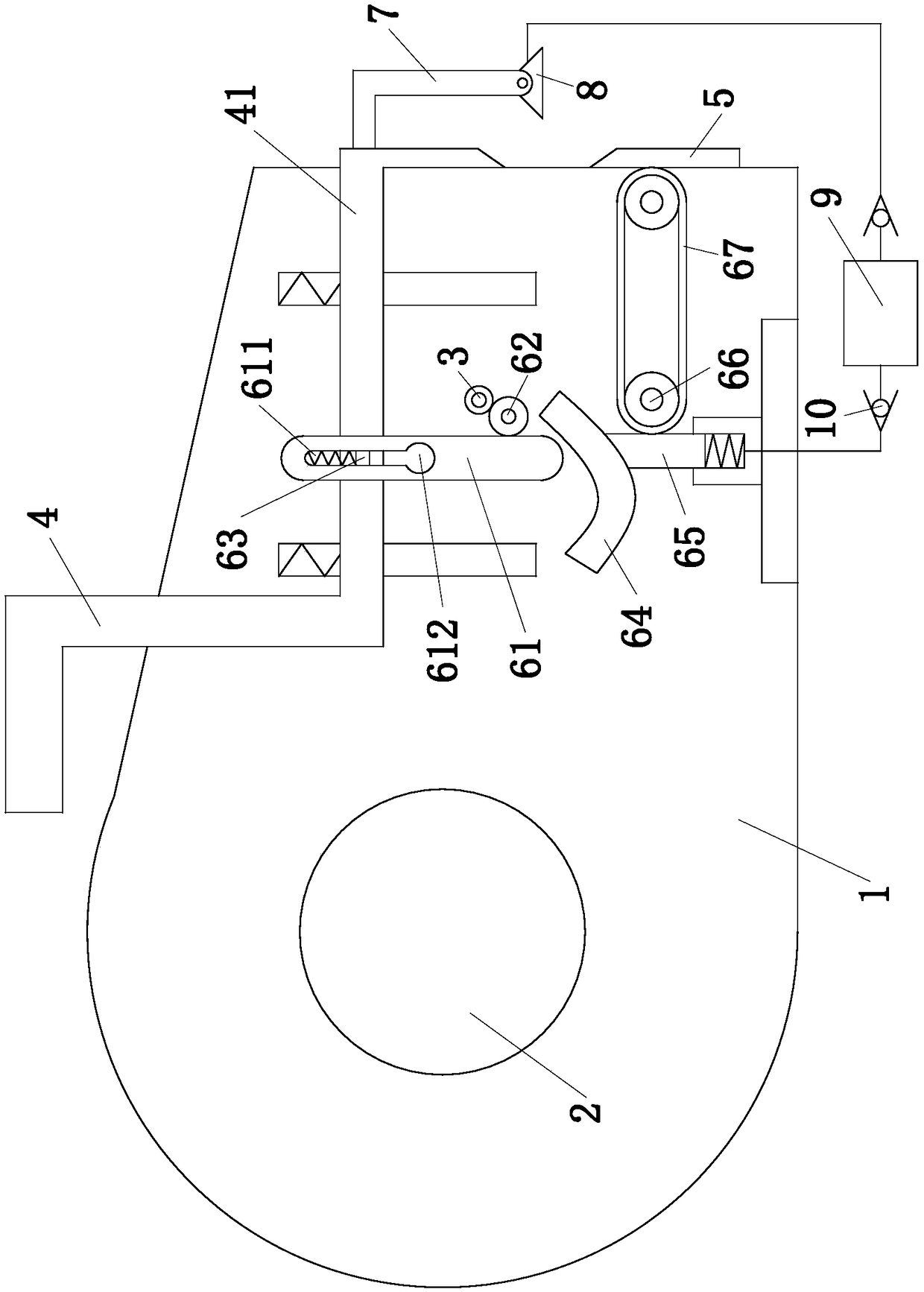

[0018] use figure 1 A tape cutter according to one embodiment of the present invention will be described below.

[0019] Such as figure 1 As shown, a tape cutting machine according to the present invention includes a support plate 1, a tape reel 2, a roller 3, a pressing member 4 and a cutter 5, the number of the support plates 1 is two, and the two support plates 1 are placed in parallel , the positions near the right end on the two support plates 1 are each vertically provided with two chutes; Reel 2 is close to the left end of support plate 1, and adhesive tape reel 2 is used for placing adhesive tape; Described cylinder 3 quantity is two, and cylinder 3 two ends are rotated and installed on two support plates 1, and cylinder 3 is near the right end of support plate 1, two The rollers 3 are arranged up and down, and the adhesive tape on the tape reel 2 passes through between the two rollers 3 and passes out from the right end of the support plate 1; the pressing member 4 inc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap