Efficient film pasting device

A film sticking device and high-efficiency technology, applied in the directions of transportation and packaging, object supply, sending objects, etc., can solve the problems of low yield rate, low efficiency, poor position accuracy, etc., and achieve cost savings, high efficiency, and improved position accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

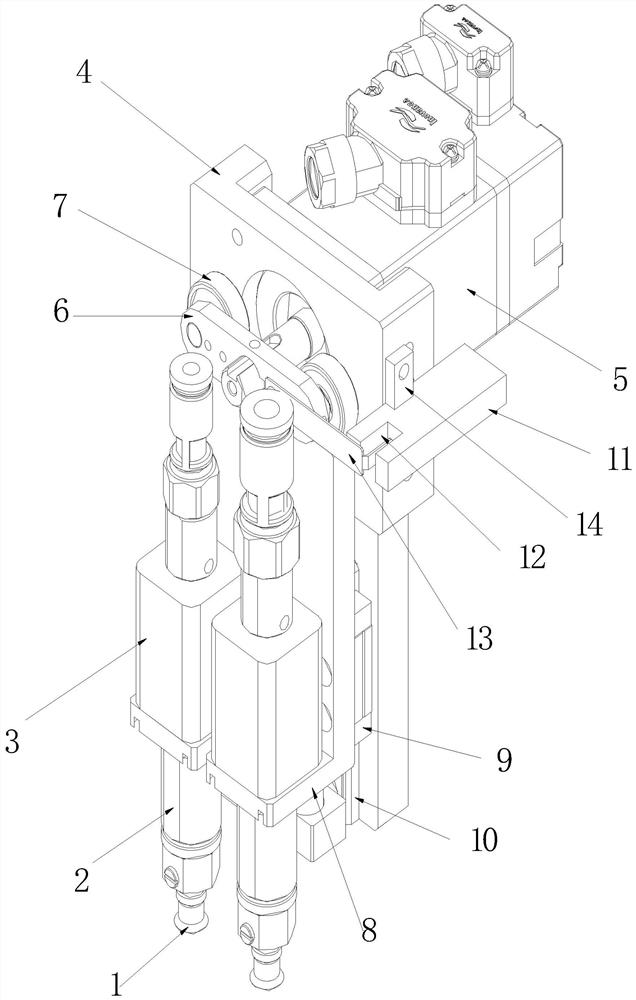

[0015] Such as figure 1 A high-efficiency film sticking device shown includes a suction head 1 for sucking the membrane, and the suction head 1 is provided with two groups, and a connecting rod 2 is arranged above the suction head 1, and the suction head 1 is connected to the The rod 2 is fixedly connected, the outer surface of the middle position of the connecting rod 2 is covered with a first motor 3 for driving the connecting rod 2 to adjust the angle, the connecting rod 2 is fixedly connected with the first motor 3, and the first One side of the motor 3 is provided with a fixed frame 4, the fixed frame 4 is provided with a moving mechanism for driving the suction head 1 to move up and down, and also includes a control assembly for controlling the high-efficiency film sticking device, the first motor 3 and the mobile The mechanisms are respect

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap