Textile gum application line

A kind of adhesive and textile technology, which is applied in the directions of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of cumbersome procedures, low production efficiency, increase production costs, etc., and achieve the effect of reducing production costs and saving processing procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

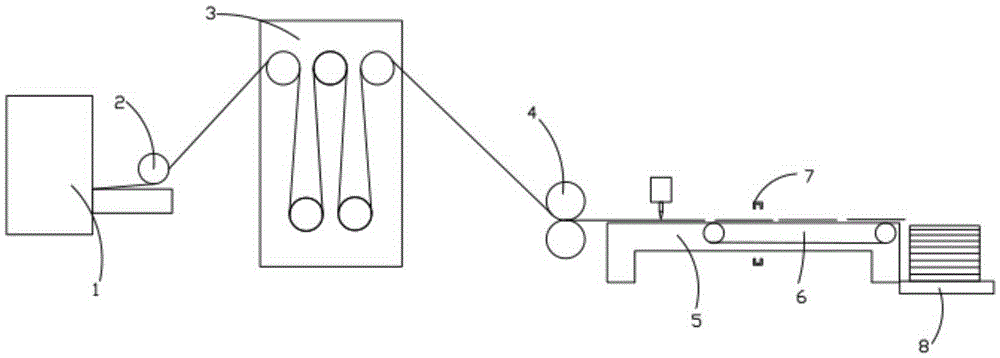

[0010] Such as figure 1 As shown, the present invention discloses a textile adhesive thread, comprising an oven 1 for heat-setting the glue on the textile cloth, a guide wheel 2 that is rotated at the outlet of the oven 1, and a storage for storing the cloth. Cloth rack 3, a pair of feed rollers 4 for leading out the cloth on the cloth storage rack 3, a cutting device 5 for cutting the cloth to length, and a conveying curtain for conveying the cut cloth pieces 6. The cloth tray 8 for receiving the cut cloth, the cloth storage rack 3 includes a frame body, a row of upper cloth storage rollers rotatably arranged on the upper part of the frame body, and a row of cloth storage rollers rotatably arranged on the frame body A row of lower cloth storage rollers at the lower part of the body, the upper cloth storage rollers are arranged staggered relative

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap