Finished product cutter of plastic uptake forming machine

A blister molding machine and blister molding technology, applied in the field of machinery, can solve the problems of high investment in equipment, long production cycle, and many processing procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

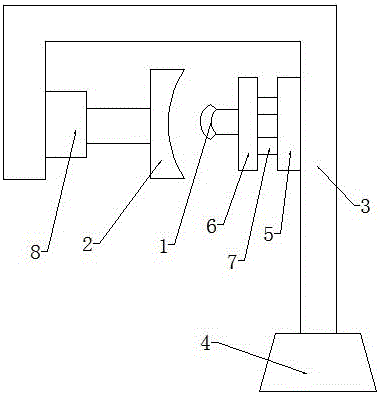

[0016] The finished product cutter of the blister forming machine includes: a stamping assembly placed on one side of the finished product exit of the blister forming machine, a knife 1 placed on the stamping assembly, and a stamping base placed on the other side of the finished product exit of the blister forming machine The table 2, the connecting rod 3 for fixing the punching assembly and the punching base 2, is fixed on the fixing seat 4 of the connecting rod 3.

[0017] The stamping assembly consists of: a stamping motor, a buffer plate 5 placed on one side of the stamping motor, and a limit plate 6 placed on the side of the buffer plate 5 and fixing the tool 1 . In order to enable the tool 1 and the limiting plate 6 to automatically reset, a return spring 7 is provided between the limiting plate 6 and the buffer plate 5 .

[0018] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap