End conveying device for transfer film

A technology of conveying device and transfer film, which is applied in the directions of transportation and packaging, sending objects, winding strips, etc., can solve the problems of increased cost, many leftover materials, and the transfer film cannot be fully utilized, and achieves the effect of high utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

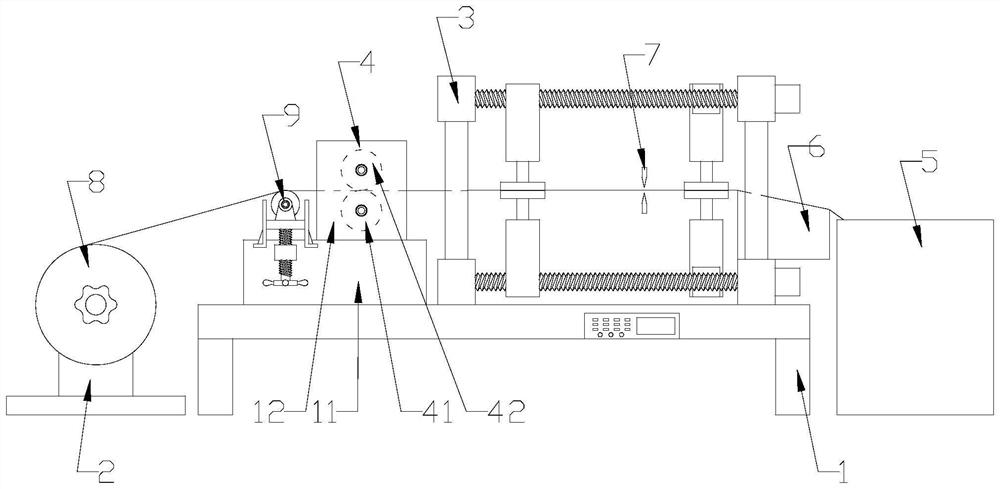

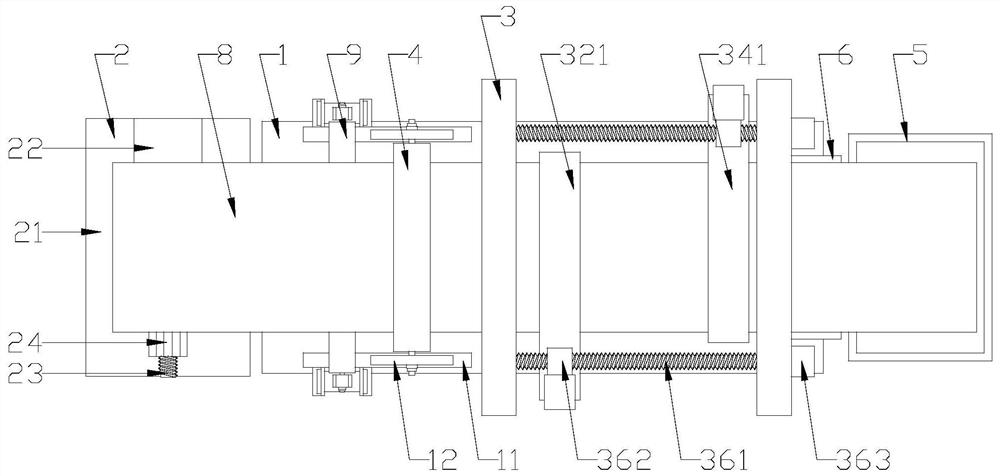

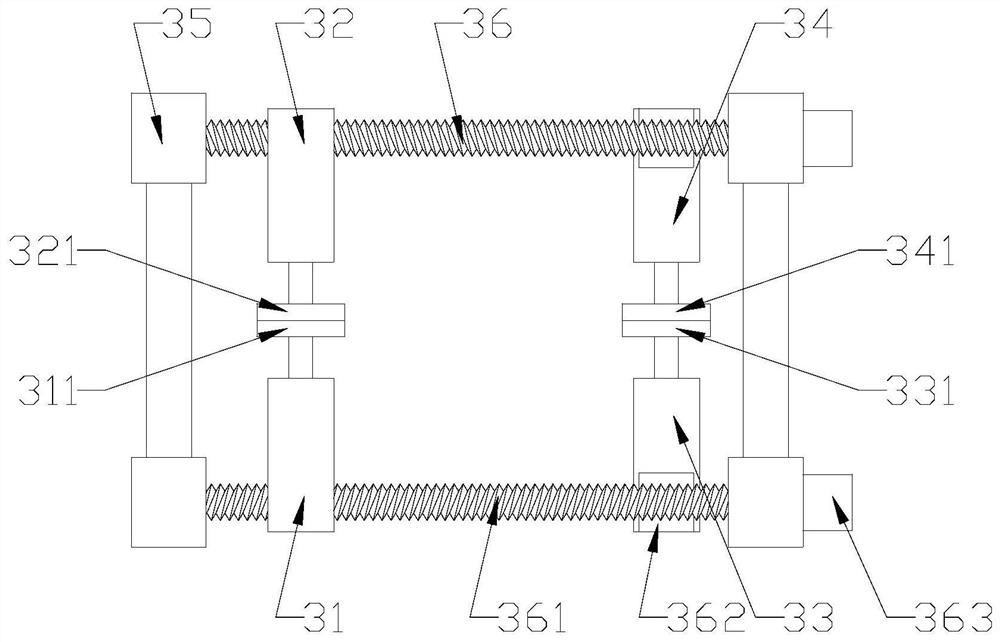

[0018] refer to Figure 1 to Figure 4 , a transfer film end conveying device according to the present invention, comprising a frame 1, a coil rack 2, a conveyor 3, a guide roller set 4, a receiving box 5 and a controller, the coil rack 2 and the receiving Material box 5 is respectively positioned at the left and right sides of frame 1, and described conveyer 3 comprises first air cylinder 31, second air cylinder 32, the 3rd air cylinder 33, the 4th air cylinder 34, conveying frame 35 and conveying driver 36, described The guide roller group 4 and the conveying frame 35 are respectively fixed on the left and right sides of the top surface of the frame 1, and the first cylinder 31 and the third cylinder 33 are respectively fixed on the front and rear sides of the bottom of the conveying frame 35. On the delivery driver 36, the second cylinder 32 and the fourth cylinder 34 are respectively fixed on the delivery driver 36 positioned at the front and rear sides of the top of the deliv

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap