Automatic overturning equipment

An automatic turning and equipment technology, which is applied to rotary conveyors, conveyor control devices, conveyors, etc., can solve problems such as complexity, complicated turning tables, and manual turning of turning tables that cannot meet the requirements, so as to improve productivity and reduce labor. strength, and the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

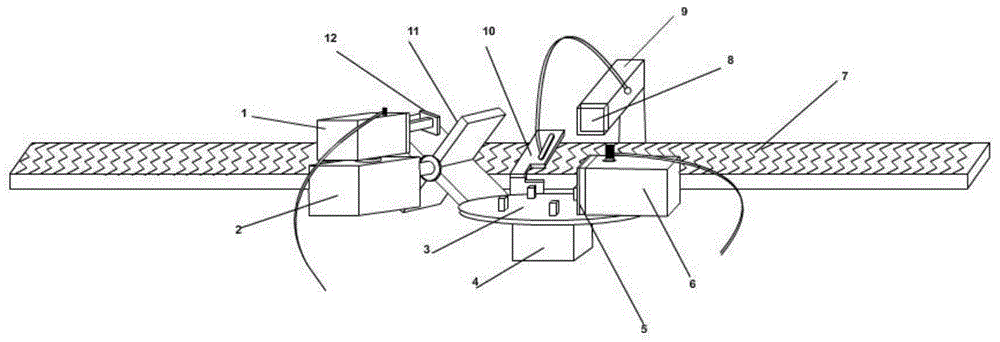

[0017] Such as figure 1 : hydraulic cylinder a1, motor a2, rotating disc 3, motor b4, push arm b5, hydraulic cylinder b6, conveyor belt 7, push arm c8, hydraulic cylinder c9, retainer 10, turning table 11, push arm a12.

[0018] An automatic overturning device, comprising: hydraulic cylinder a1, motor a2, rotating disk 3, motor b4, push arm b5, hydraulic cylinder b6, conveyor belt 7, push arm c8, hydraulic cylinder c9, blocking plate 10, turning table 11, push arm a12. Among them, the hydraulic cylinder a1 is set on the motor a2, the push arm a12 is connected to the hydraulic cylinder a1, the turning table 11 is connected to the motor a2, the surface of the rotating disk 3 is at the same level as the axis of the motor a2, the rotating disk 3 is ar

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap