Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Tuyere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tuyere or tuyère ([tɥijɛʁ]; English: /twiːˈjɛər/) is a tube, nozzle or pipe through which air is blown into a furnace or hearth. Air or oxygen is injected into a hearth under pressure from bellows or a blowing engine or other devices. This causes the fire to be hotter in front of the blast than it would otherwise have been, enabling metals to be smelted or melted or made hot enough to be worked in a forge, though these are blown only with air. This applies to any process where a blast is delivered under pressure to make a fire hotter.

Acquisition system for collecting particles of different particle size discharged by fire coal

InactiveCN103323292AEasy to carryGood effectWithdrawing sample devicesPreparing sample for investigationParticulatesCombustion

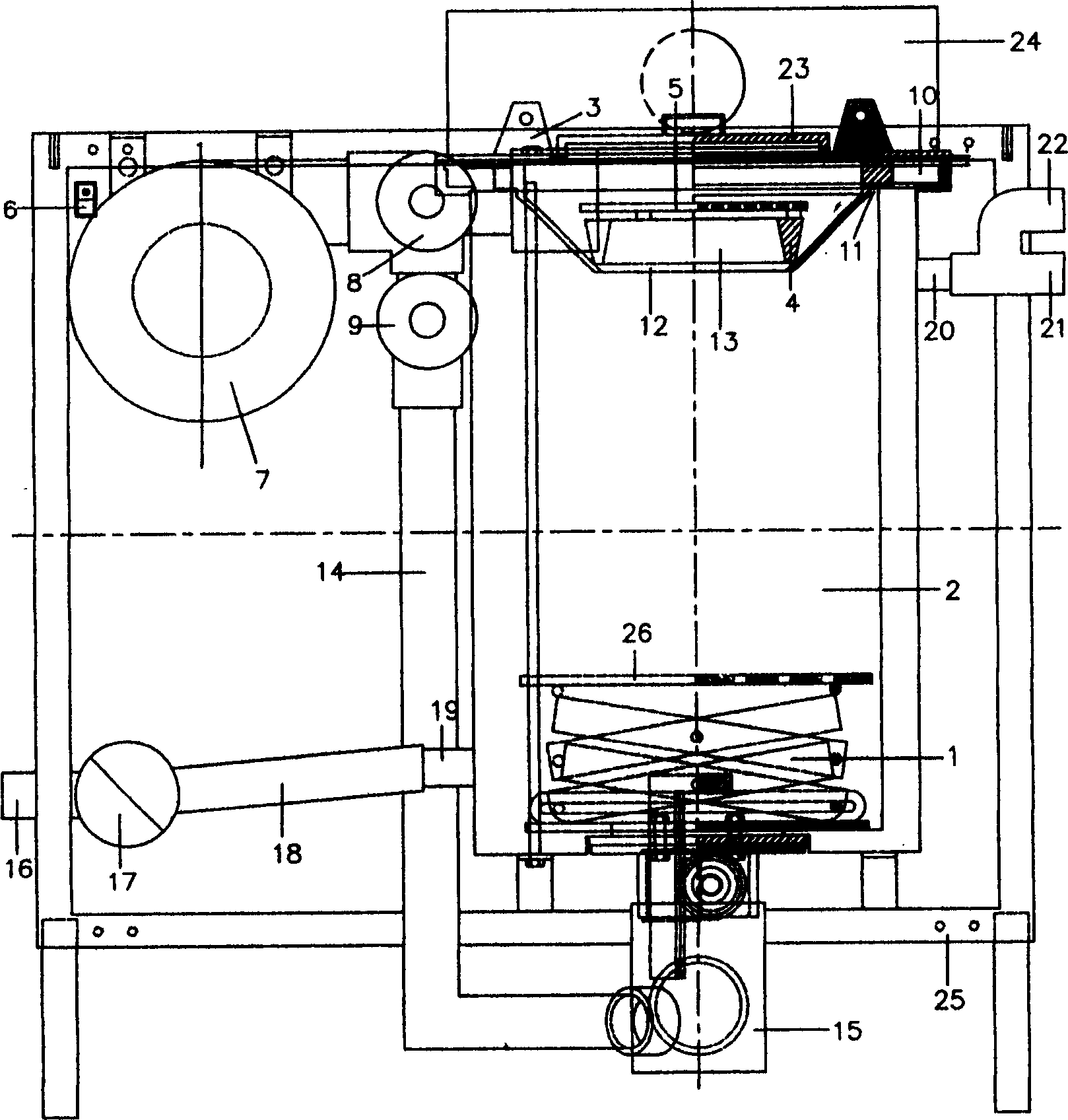

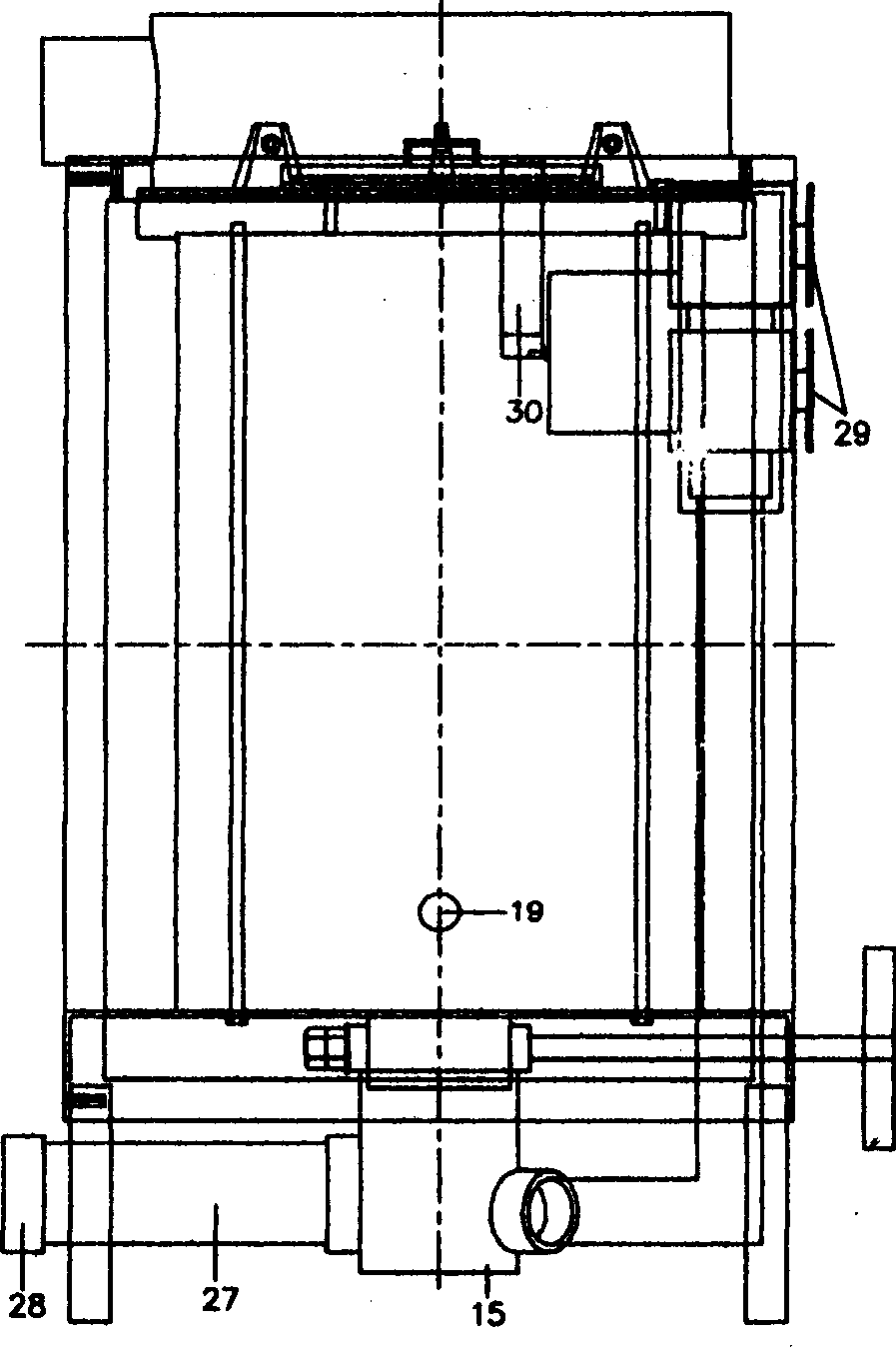

The invention relates to an acquisition system for collecting particles of different particle size discharged by fire coal. The acquisition system comprises a flue gas collecting box, a flue gas pipeline, a slide plate with wheels, a civil coal-fired furnace, a blower, a frequency converter, a condenser tube, a temperature sensor, a MCI sampler and a MOUDI sampler. The flue gas collecting box, the flue gas pipeline and the slide plate with wheels are made of stainless steel; the civil coal-fired furnace is put inside the flue gas collecting box; the blower can blow air into the flue gas collecting box to dilute flue gas and provide oxygen for combustion; and the particles in the air are filtered by a filter cloth of 120 meshes at the blower air inlet. The apparatus in the invention avoids the defects that original particles in the air cannot be purified to enter the acquisition system, dilution multiple of fire coal flue gas cannot be calculated and flue gas temperature cannot be adjusted, the original apparatus is not convenient for carrying and condensation enters into sampler flue gas etc. The experiment result shows that the effect of collecting particles of different particle size that are discharged by fire coal is obvious and the sampling operation is simple.

Owner:SHANGHAI UNIV

Flue gas desulfurization and denitration system and method

The invention discloses a flue gas desulfurization and denitration system and method, and belongs to the technical field of flue gas processing. The system comprises a pre-deduster, a rotating spray desulfurization and denitration system, an induced draft fan and a chimney, a circulating fluidized bed desulfurization system is arranged between the rotating spray desulfurization and denitration system and the induced draft fan, and a flue gas mixing axial adjustment damper is arranged between the rotating spray desulfurization and denitration system and the circulating fluidized bed desulfurization system; the system further comprises a booster conveying fan, a material conveying pump I and a material conveying pump II. Accordingly, the rotating spray desulfurization and denitration systemand the circulating fluidized bed desulfurization system are combined, step-by-step desulfurization and denitration on flue gas are achieved, and the desulfurization and denitration efficiency is high; due to step-by-step desulfurization and denitration, the system and method can be applied to desulfurization and denitration processing of the flue gas high in sulfur content and nitrate content, and the application range is high.

Owner:NANJING SHIBO ENVIRONMENTAL PROTECTION TECH CO LTD

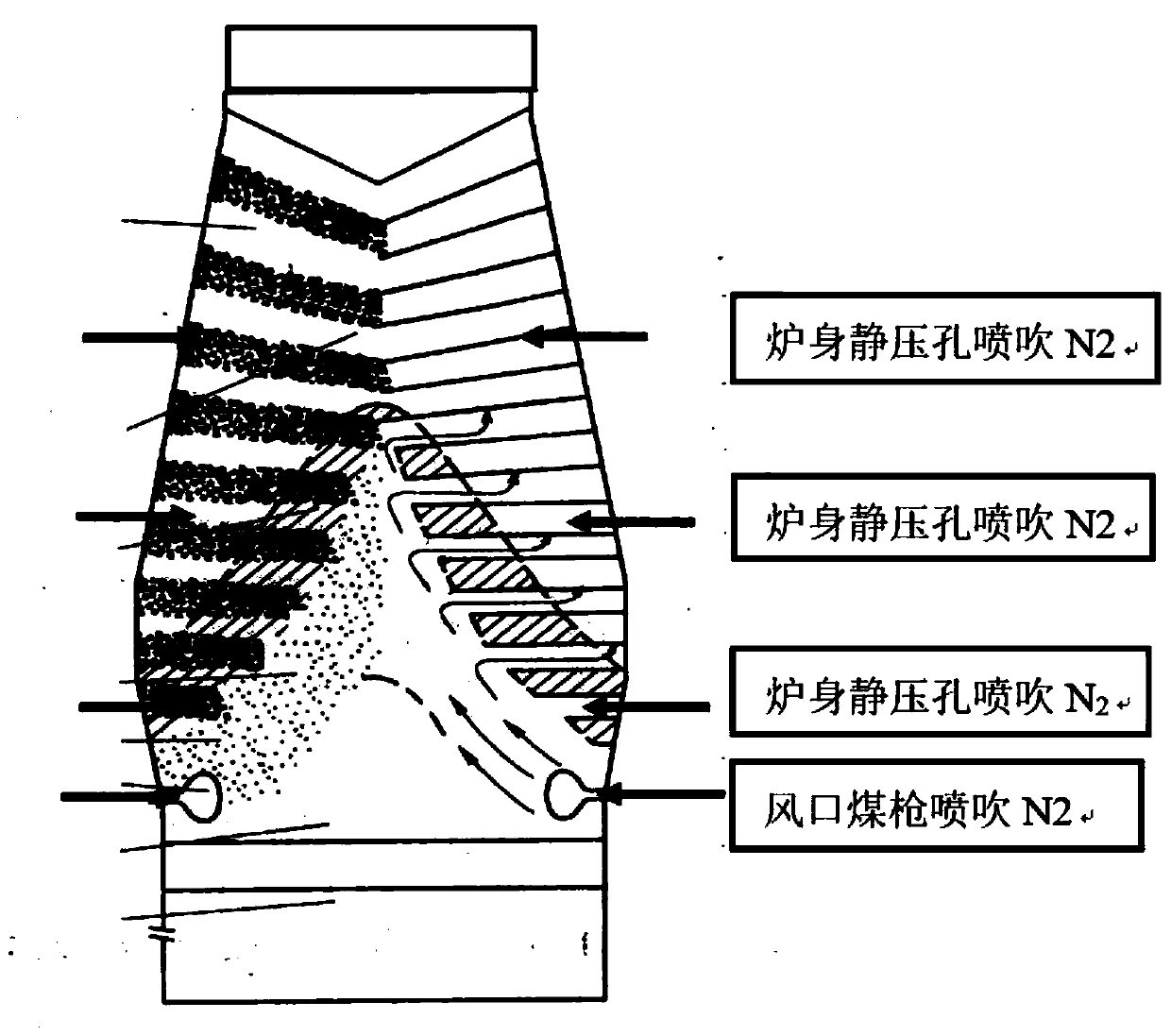

Blast furnace stockline descending top temperature controlling and detonation preventing method

InactiveCN110229937AReduce the temperatureAvoid direct contactBlast furnace componentsBlast furnace detailsDetonationEngineering

Owner:武汉钢铁有限公司

Heating and evaporation device for feeding of uranium enrichment plant

InactiveCN109269562AAvoid overheatingPrevent overloadMeasurement devicesIsotope separationEvaporationEngineering

Owner:中核第七研究设计院有限公司

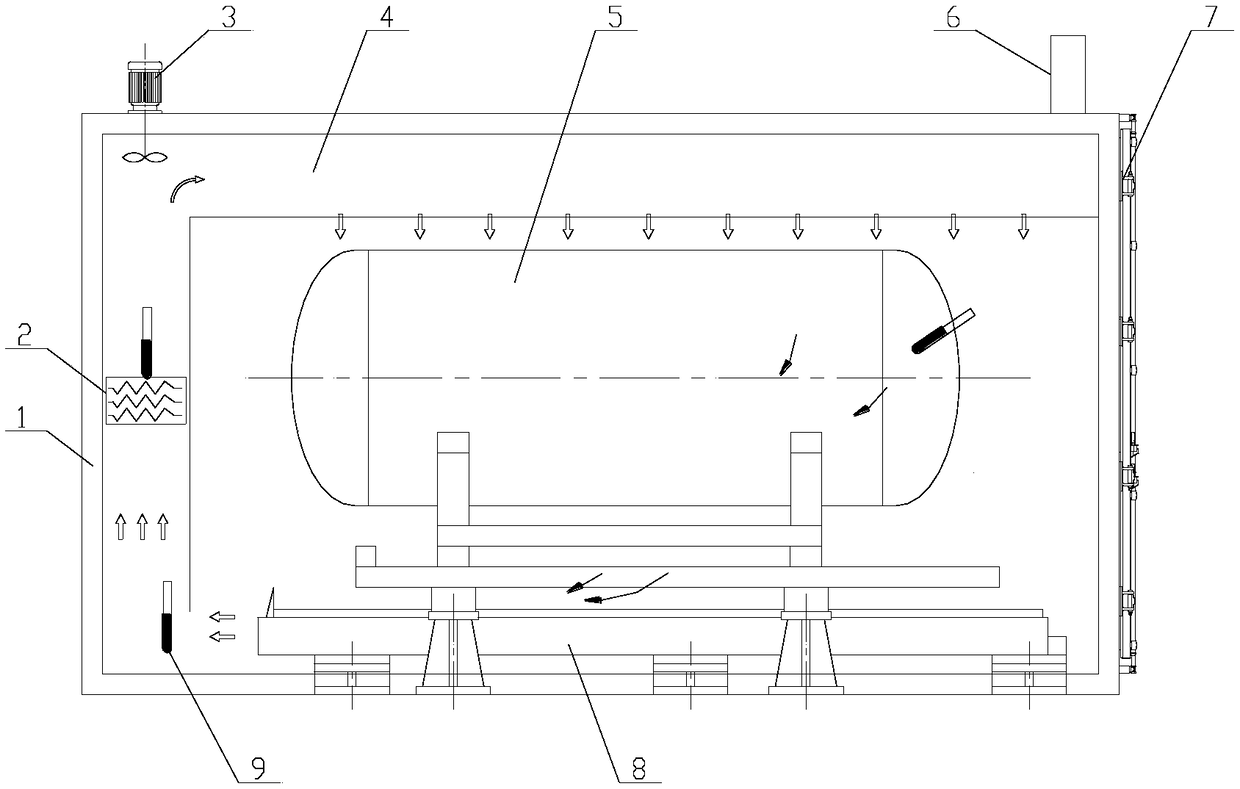

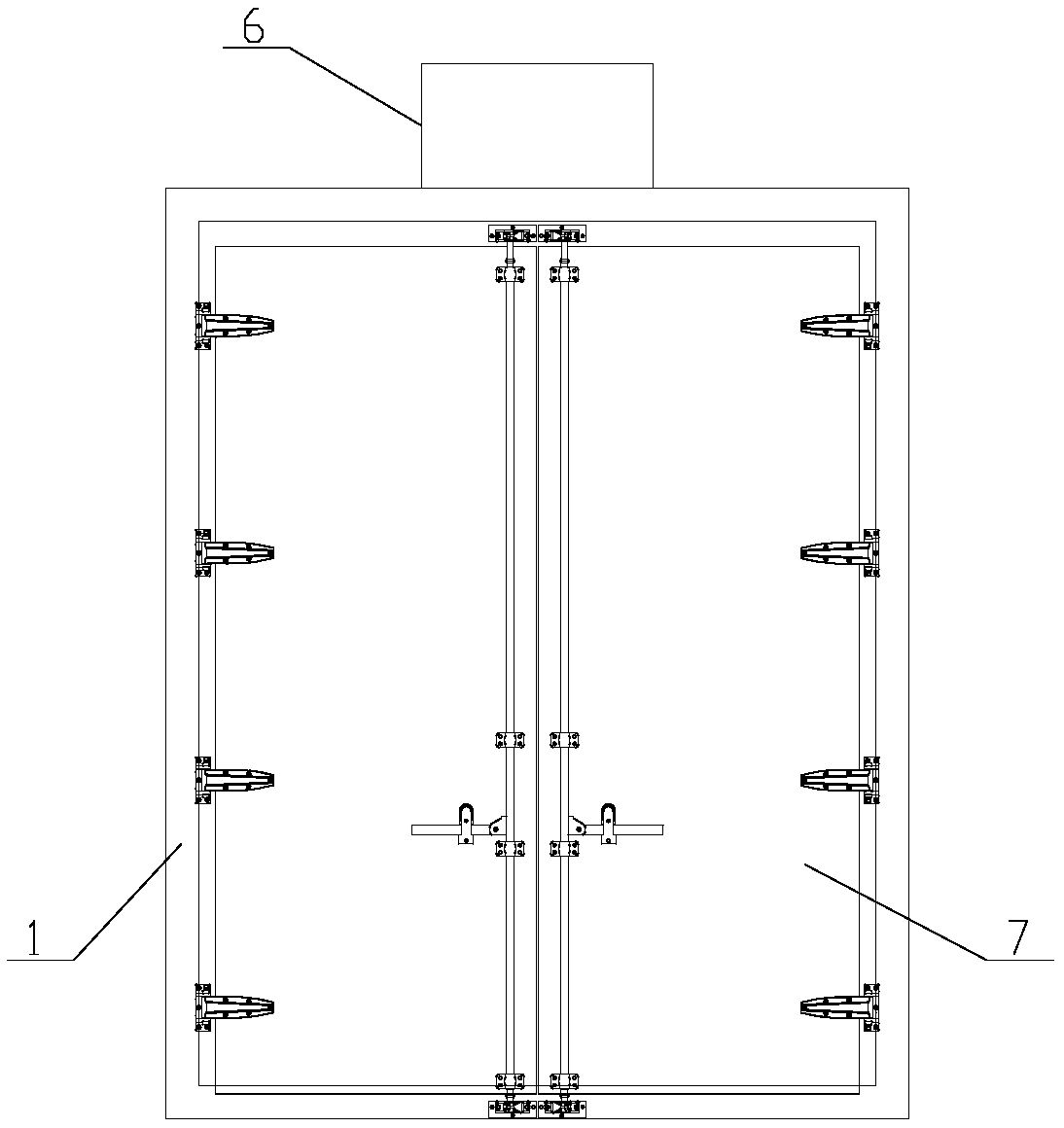

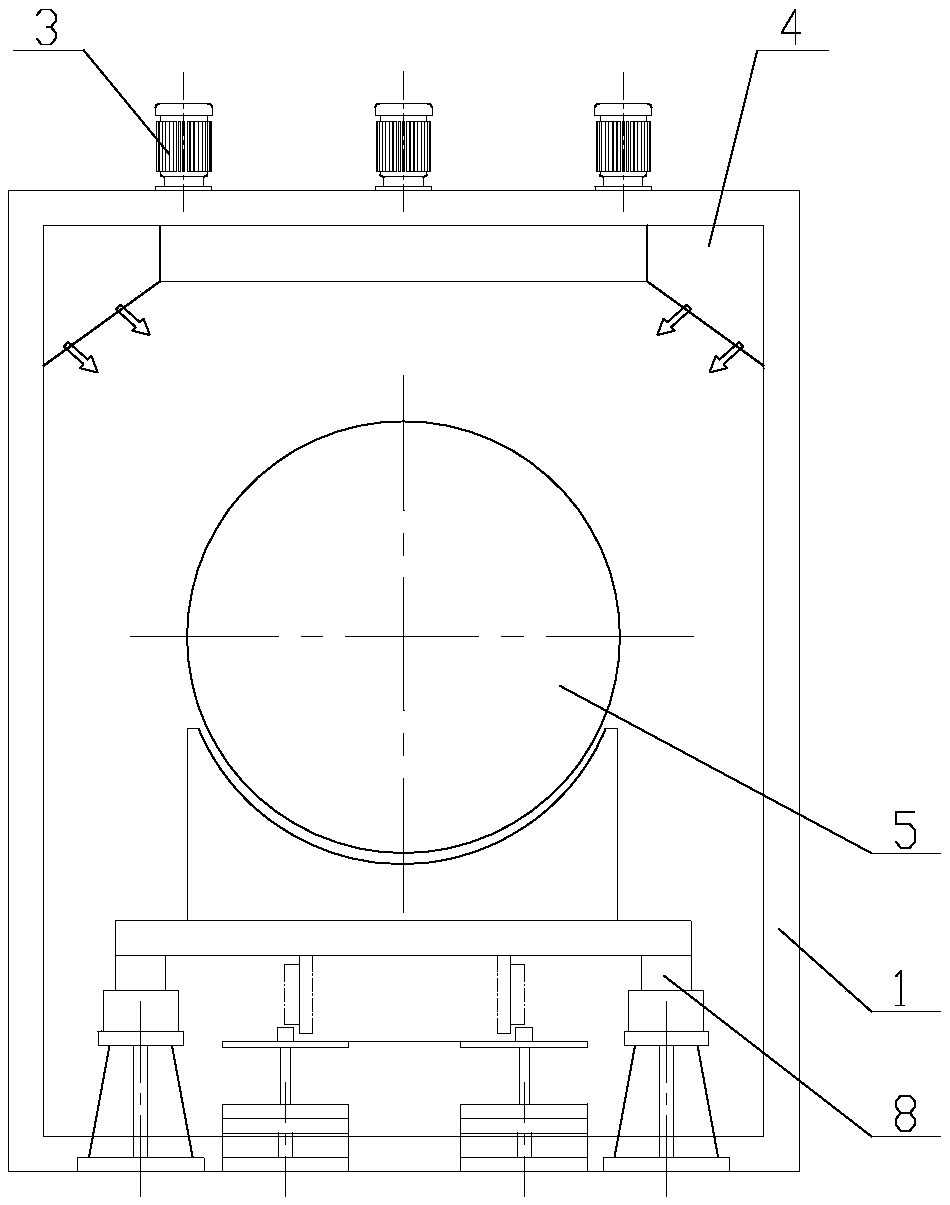

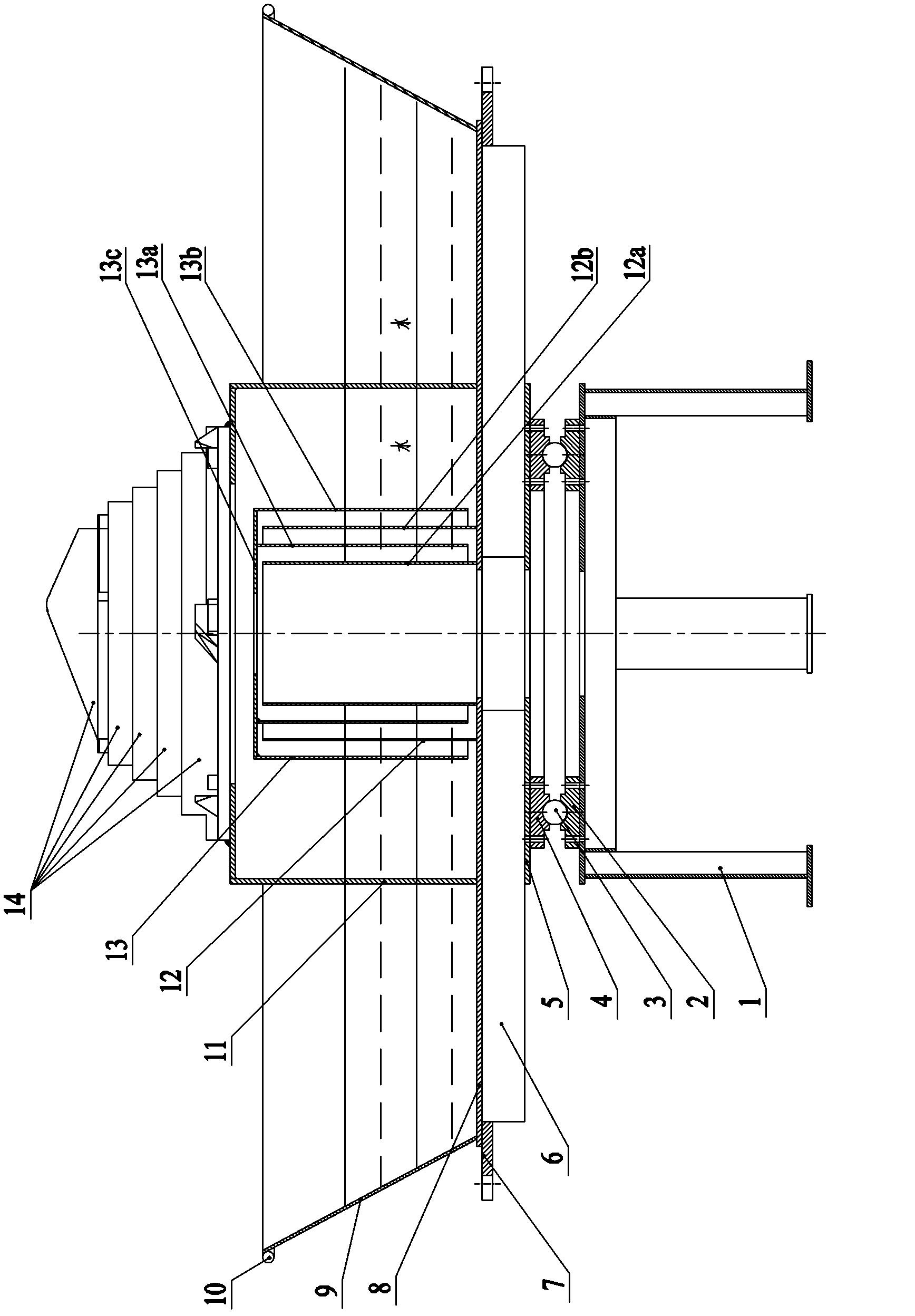

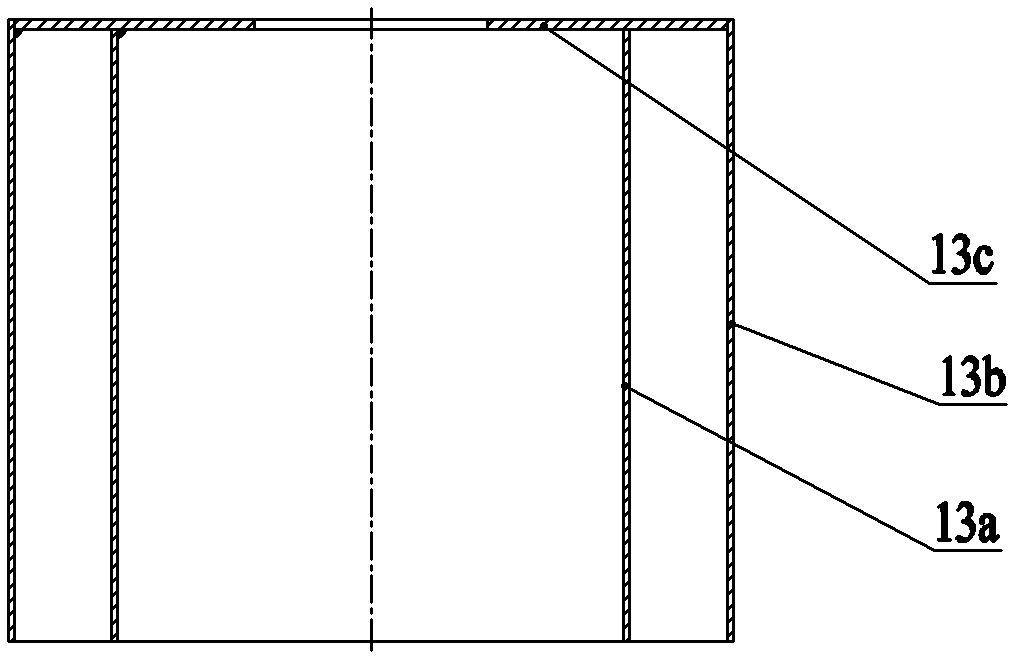

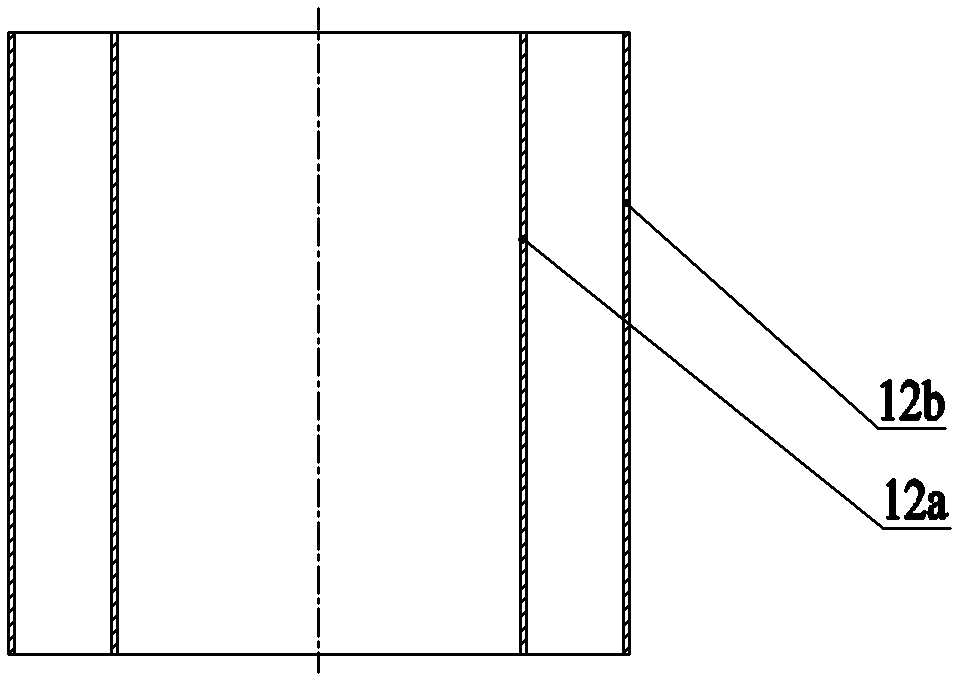

Drying oven with double air channels for heat setting machine

InactiveCN104420037AReduce resistanceUniform and stable airflowTextiles and paperEnvironmental resistanceProcess engineering

The invention discloses a drying oven with double air channels for a heat setting machine. The drying oven comprises a heat-insulation oven body and two hot-air blowing devices. The hot-air blowing devices are positioned in the heat-insulation oven body, a heat-insulation door is arranged on the heat-insulation oven body, the hot-air blowing devices are connected with a flow guide plate, the flow guide plate is connected with air outlets of a fan, air inlets of the fan are sequentially connected with a natural gas heating system, and the two hot-air blowing devices are respectively positioned above and below needle plates. The drying oven has the advantages that the flow guide plate is arranged at the air outlets of the fan and is connected with the hot-air blowing devices, the double air channels can be formed by the two hot-air blowing devices, the two hot-air blowing devices are respectively positioned above and below the needle plates, accordingly, airflow can uniformly smoothly flow, resistance on the airflow can be reduced, and heat setting effects can be guaranteed; the drying oven is provided with the natural gas heating system and is high in heating-up speed, the heating-up preparation time of the drying oven can be shortened, the drying oven is low in pollution and easy to maintain, the energy utilization rate of the drying oven can be maximized, accordingly, production requirements can be met, the production cost can be greatly reduced, integral production procedures are environmental friendly, and energy can be saved in the integral production procedures.

Owner:WUXI CITY HUAYANG DYEING & FINISHING MACHINERY

Drying device for fluororesin particle production

InactiveCN108534492AEasy to moveImprove drying efficiencyGranular material dryingDrying gas arrangementsEngineeringAir heater

The invention discloses a drying device for fluororesin particle production. The drying device for fluororesin particle production comprises a drying barrel; a base is arranged on the lower side of the drying barrel, and a swinging device is connected between the drying barrel and the base; a feeding port is formed in the top of the end, away from the swinging device, of the drying barrel, and anair inlet is formed in the end, close to the feeding port, of the drying barrel; the end, away from the drying barrel, of the air inlet is connected with a corrugated pipe; the end, away from the airinlet, of the corrugated pipe is connected with an air heater; a stirring device is arranged in the drying barrel, and comprises a stirring rotating shaft, stirring rods and stirring balls; the stirring rotating shaft is rotationally connected in the drying barrel; the uniformly distributed stirring rods are arranged on the outer side of the stirring rotating shaft; each stirring rod is provided with the corresponding stirring balls at equal intervals; and a stirring motor is installed at the end, away from the air inlet, of the drying barrel through a screw. According to the drying device forfluororesin particle production, fluororesin particles are dried through hot air, in the drying process, the stirring device and the swinging device are used for increasing flowing of the fluororesinparticles, and the drying efficiency is improved.

Owner:HUZHOU HEXUANZHU NEW MATERIAL TECH CO LTD

Chemical waste incinerator

InactiveCN111928250ABurn fullyReduce the likelihood of an explosionIncinerator apparatusCombined combustion mitigationCombustorExhaust fumes

The invention discloses a chemical waste incinerator. The chemical waste incinerator comprises a furnace body, wherein a feed hopper is arranged on one side of the furnace body, a feed inlet is formedin the upper end of the feed hopper, a baffle plate is arranged in the position, corresponding to the feed hopper, of the interior of the furnace body, a rotating roller is arranged in the feed hopper, a guide blade is arranged on the rotating roller, a burner is arranged in the furnace body, an ash discharge hopper is arranged below the furnace body, an air supplement opening is arranged on oneside of the furnace body, a waste heat recovery device is arranged at the upper end of the furnace body, an air outlet is arranged at the top end of the furnace body, a water tank is arranged on one side of the furnace body, an air outlet pipe is arranged at the air outlet, an air exhaust opening is arranged on the water tank, and a spraying device is arranged in the furnace body. A user directlydumps chemical engineering garbage into the feed hopper, materials are conveyed through the inner guide blade, the baffle plate is pushed away under the action of gravity, the materials enter the furnace body for combustion, oxygenation work is regularly carried out through an air supplement opening, the interior of the furnace body is fully combusted, and then generated hot waste gas is subjectedto heat exchange work through the waste heat recovery device at the top.

Owner:HUNAN DELI SAFETY & ENVIRONMENTAL PROTECTION TECH CO LTD

Air intake and deslagging device of coal gas producer

InactiveCN102504874APrevent leakageIngenious and reasonable structureCombustible gas productionSlagEngineering

Owner:WUXI LAIDA HOT WORKING ENGIN

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap