Air intake and deslagging device of coal gas producer

A gas generator and air intake technology, which is applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problem that the slagging effect is not particularly good, and achieve the effects of convenient slagging, prevention of gas leakage and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings and embodiments.

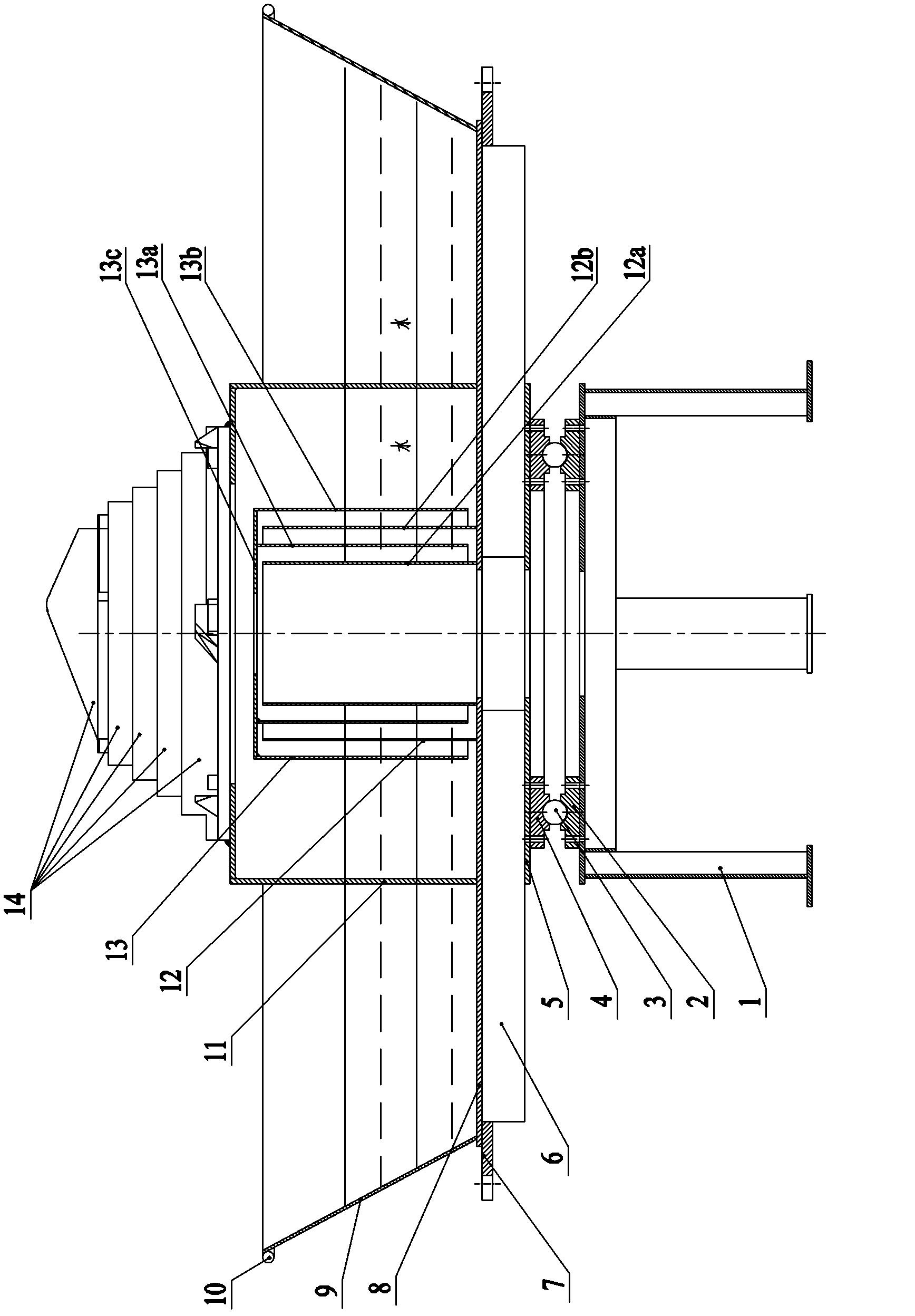

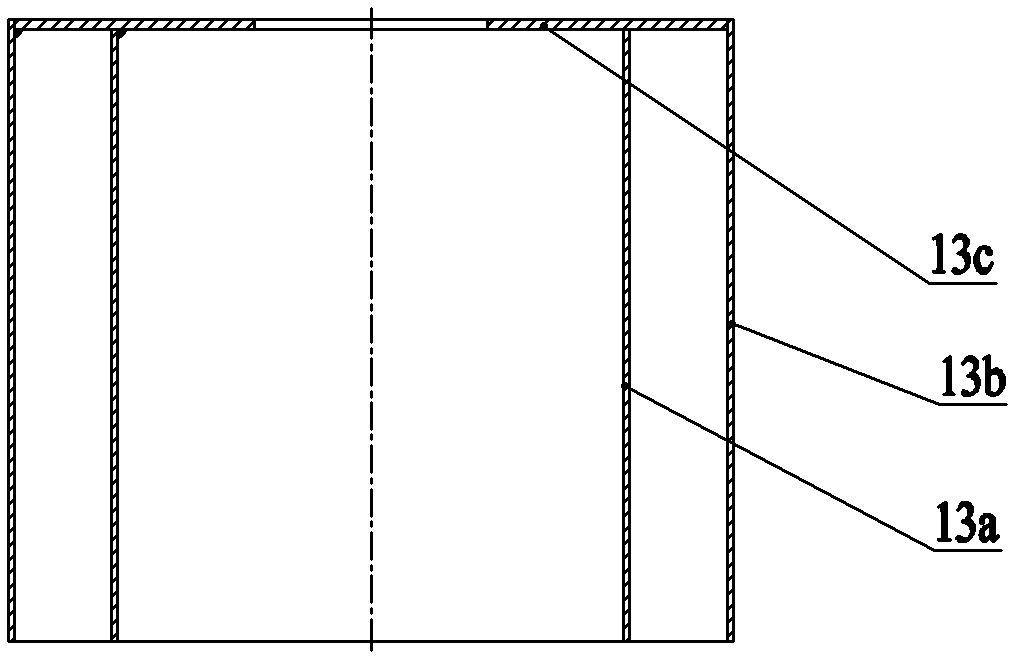

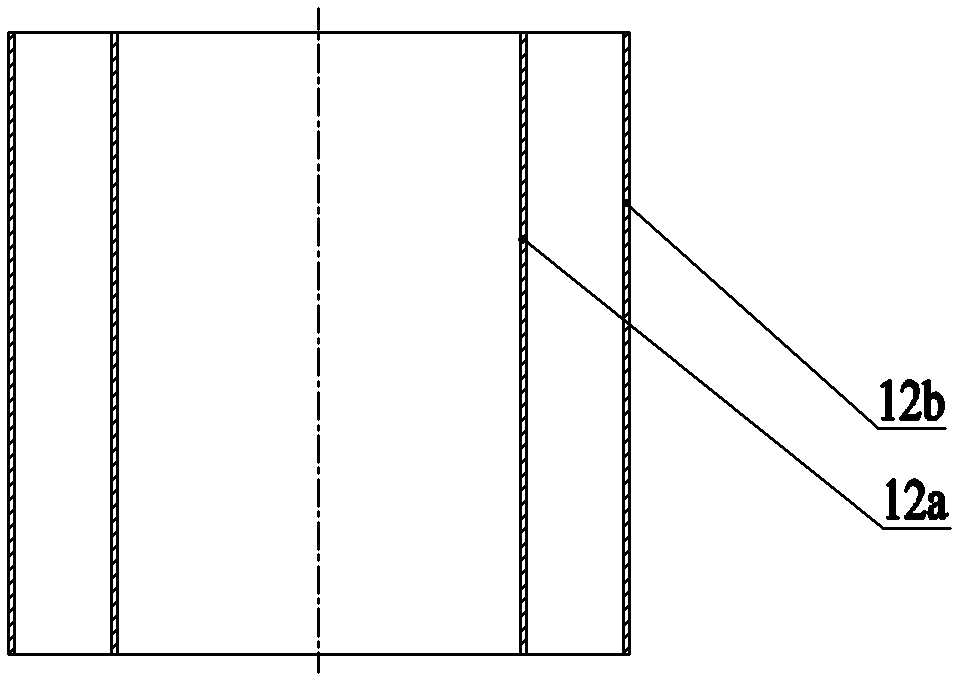

[0017] As shown in the figure: the air inlet and slagging device of the gasifier in the embodiment mainly consists of a base 1, a rolling support assembly, a guide rail bottom plate 5, a bracket 6, a ratchet 7, an ash tray bottom plate 8, a conical ash tray 9, and a wind cap Seat 11, hood assembly 14 and sealing assembly are formed.

[0018] Such as figure 1 As shown, the bracket 6 is supported and installed on the base 1 by a rolling support assembly, and a ratchet 7 is installed on the bracket 6, and the ratchet 7 is pushed and rotated by a mechanical push rod, and the ratchet 7 can drive the bracket 6 to rotate on the base 1; 8 is fixedly installed on the top of the support 6, the lower edge of the conical ash tray 9 is welded and fixed with the periphery of the ash tray bottom plate 8, the hood seat 11 is welded and fixed at the center position in the conical

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap