Heating and evaporation device for feeding of uranium enrichment plant

A technology for heating evaporation and enrichment plants, applied in the field of uranium enrichment, which can solve the problems of setting too many feeding device points, occupying the feeding device for a long time, and not being able to realize online monitoring, so as to achieve improved intrinsic safety and low manufacturing cost , The effect of saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

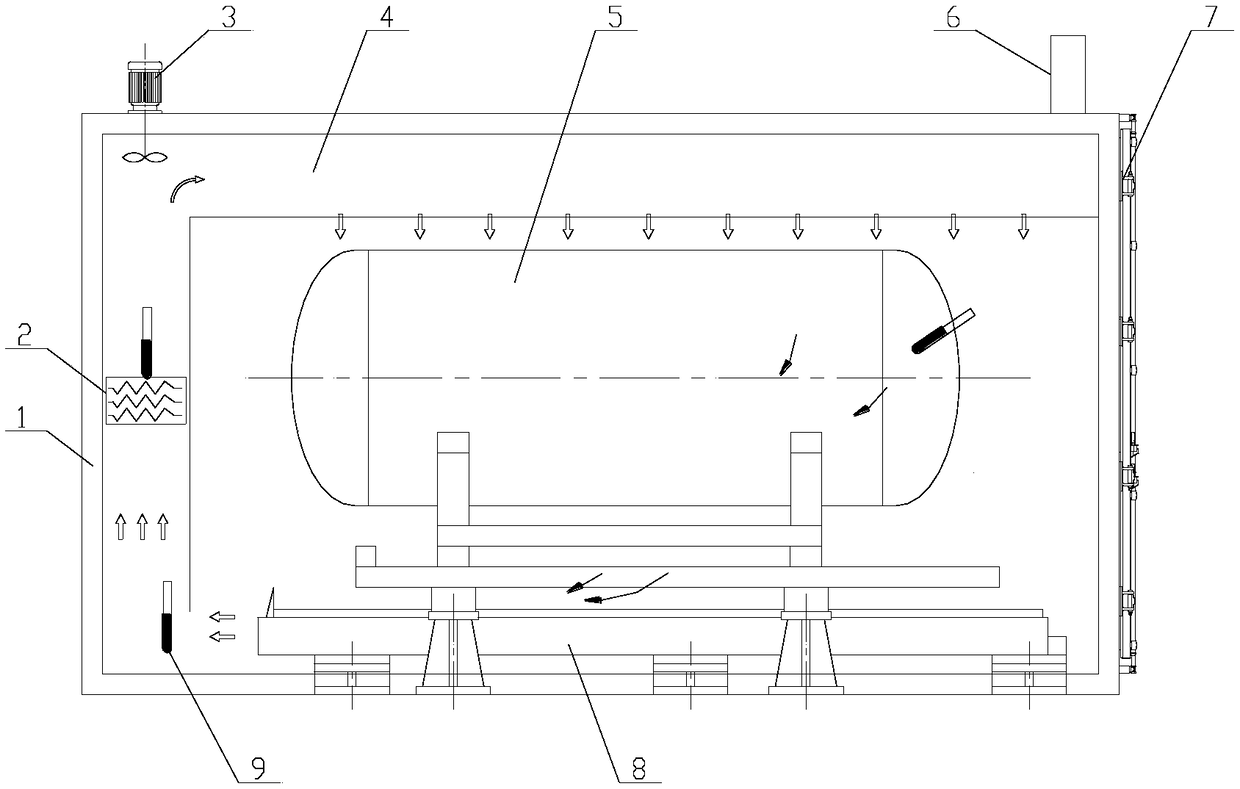

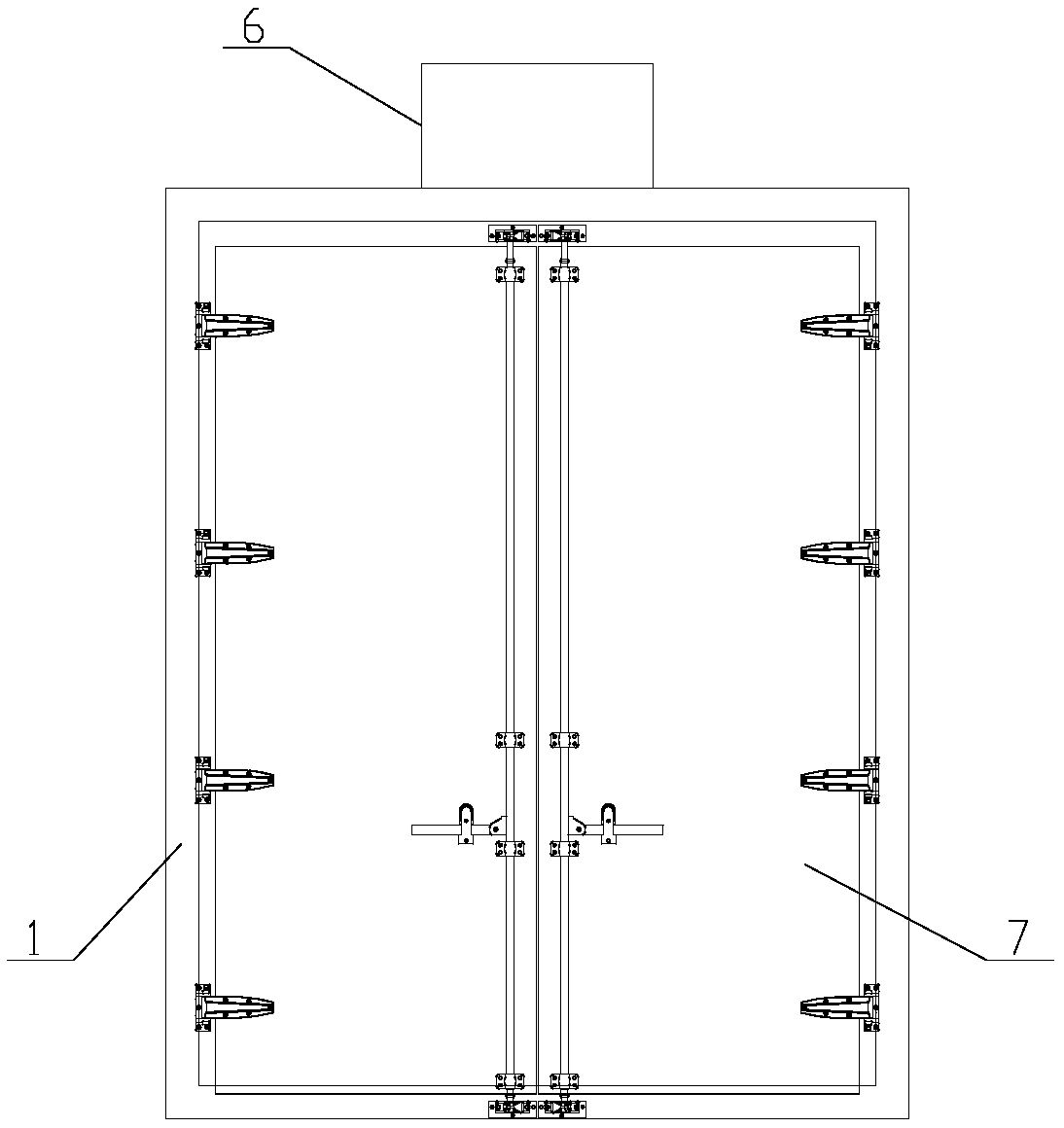

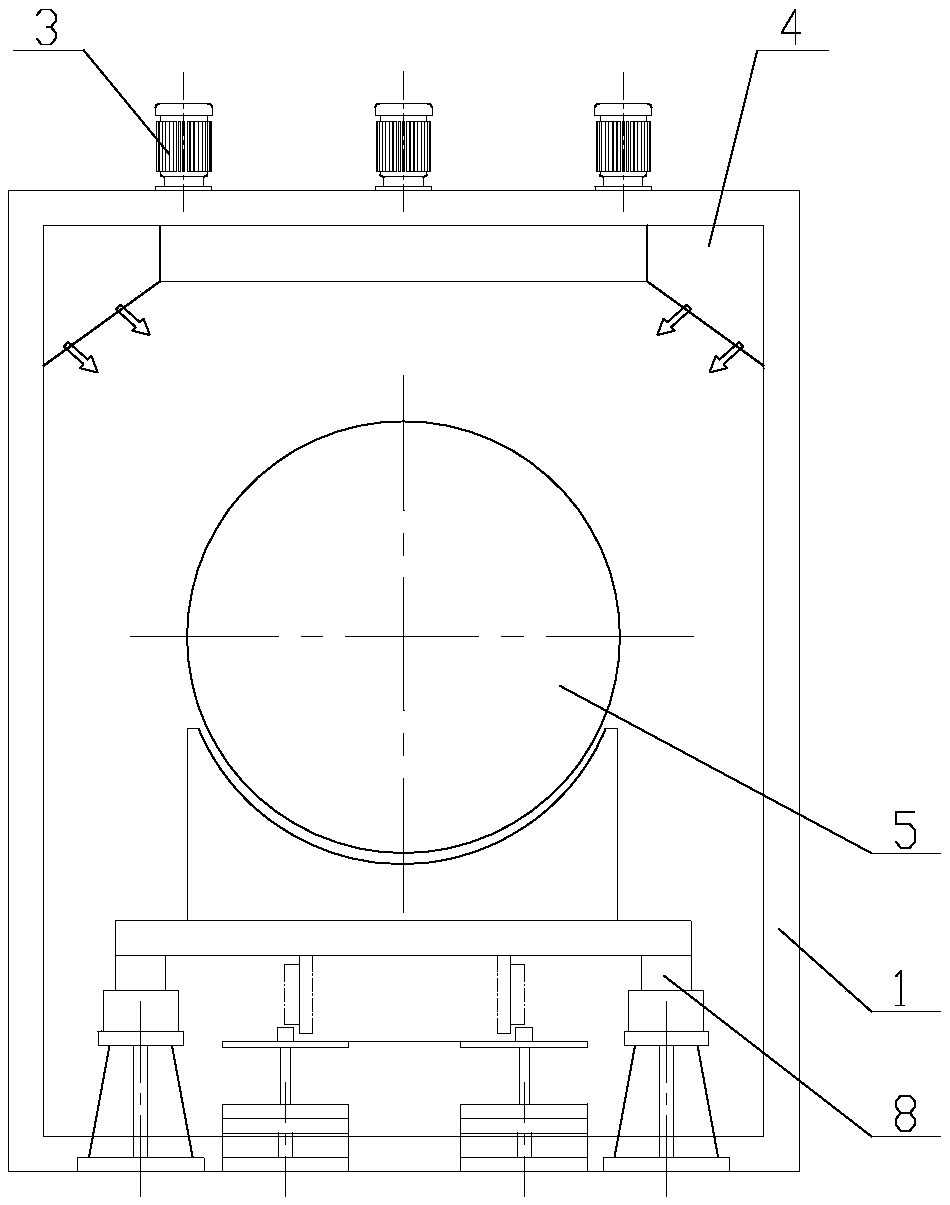

[0044] Such as Figure 1~3 A heating and evaporating device for feeding materials in a uranium enrichment plant shown, including a box body 1, an electric heater 2, a circulating fan 3, an air duct 4, a feeding container 5, an LED display screen 6, a gate 7, containers and rail supports Component 8, temperature detection instrument 9 and DCS system.

[0045] The box body 1 is a cuboid structure with a lateral width greater than its longitudinal height and can be used in conjunction with rail transport vehicles in uranium enrichment plants. The box body 1 is formed by splicing insulation material boards.

[0046] The feed container 5 is a cylindrical cavity structure, which is arranged inside the box body 1. The central axis of the feed container 5 is parallel to the transverse axis of the box body 1, and the central axis of the feed co

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap