Sealing structure and gate valve with sealing structure

A sealing structure and sealing failure technology, applied in shaft sealing, engine sealing, sliding valve and other directions, can solve the problem that the sealing structure cannot meet the continuous sealing and permanent sealing at the same time, and achieve small deformation and small extrusion force. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

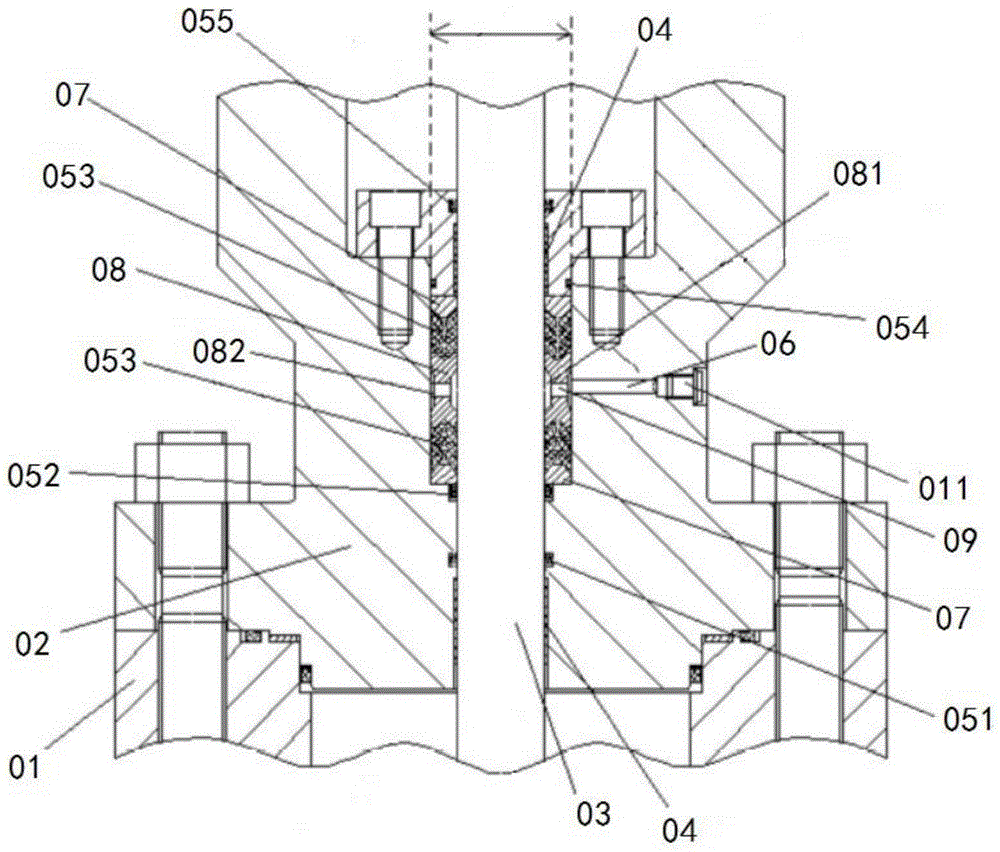

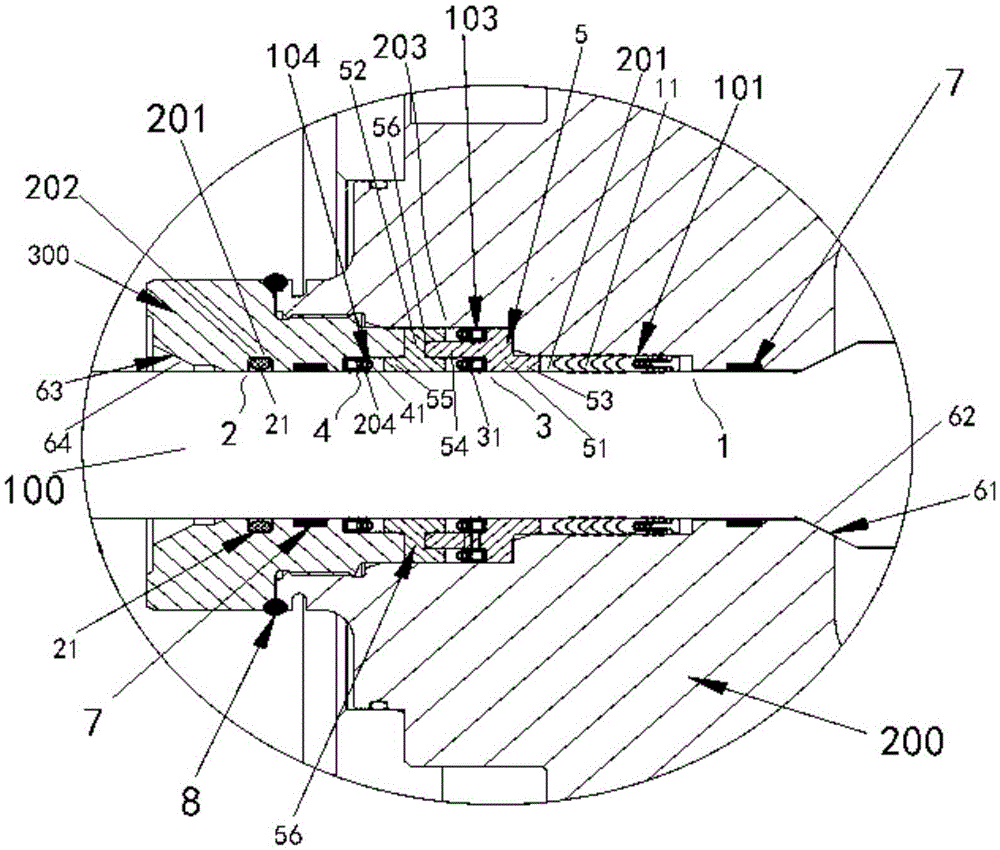

[0051] This embodiment provides a sealing structure, which is suitable for being arranged between the valve stem 100 and the valve cover 200 sleeved on the valve stem 100, refer to Figure 2-3 shown, including:

[0052] The first seal 1 is used to seal one end of the valve stem 100;

[0053] The second seal 2 is used to seal the other end of the valve stem 100;

[0054] The third seal 3 is arranged between the first seal 1 and the second seal 2, and close to the first seal 1, and replaces the first seal only when the seal of the first seal 1 fails 1 to act as a seal;

[0055] The fourth seal 4 is arranged between the first seal 1 and the second seal 2 and close to the second seal 2, and only replaces the second seal when the seal of the second seal 2 fails 2 play a sealing role.

[0056] In the sealing structure in this embodiment, a first seal 1 and a second seal 2 are respectively provided at both ends of the valve stem 100, and at least one third seal 3 and at least one th

Embodiment 2

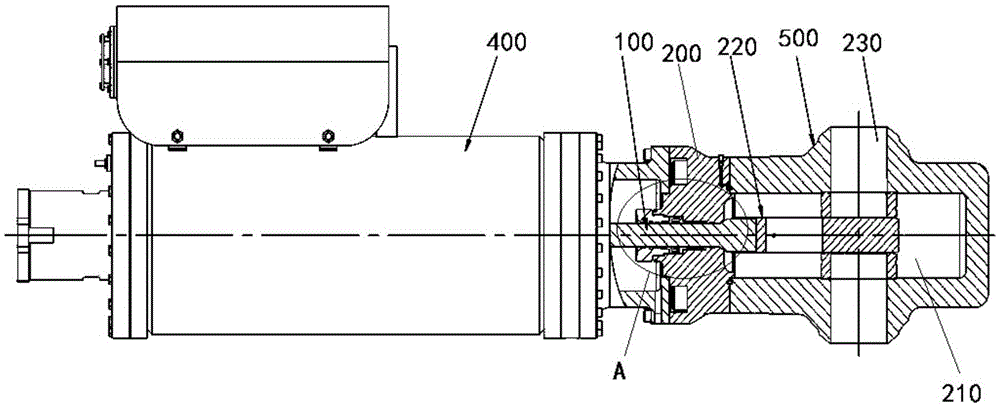

[0086] This embodiment provides a gate valve, including:

[0087] The driving mechanism 400 has an output shaft;

[0088] The valve body 500 has an inner cavity 210, the inner cavity 210 has a gate 220 inside, and a pipe 230 that can be opened or sealed closed by the gate 220;

[0089] The valve stem 100 is fixedly connected to the output shaft at one end, and fixedly connected to the gate plate 220 at the other end, so as to drive the gate plate 220 to move under the drive of the driving mechanism 400, thereby driving the gate plate 220 to open or close said conduit 230;

[0090] The valve cover 200 is sleeved on the outside of the valve stem 100 and fixedly connected to the valve body 500 and the driving mechanism 400;

[0091] A sealing structure as described in Embodiment 1 is also provided between the valve cover 200 and the valve stem 100 .

[0092] The gate valve of this embodiment has the sealing structure described in Embodiment 1, and therefore has the advantages bro

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap