Reactive dye formula for cotton/linen blending and preparing method thereof

A technology for reactive dyes and a production method, applied in the field of reactive dye formulations, can solve the problems of low color yield, low color fastness and wet rubbing fastness, loss of surface activity, etc. The effect of rubbing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

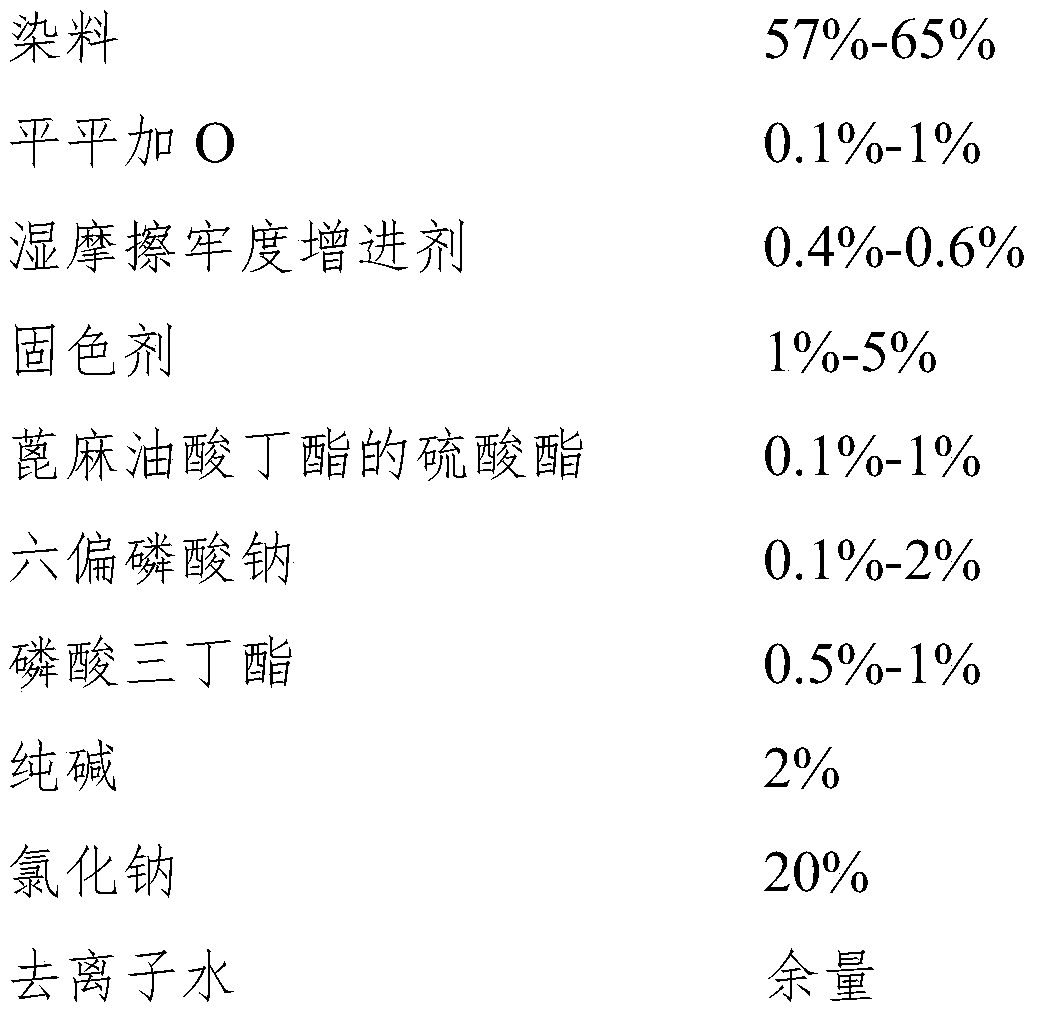

[0021] A reactive dye formula for cotton and linen blending and a preparation method thereof, the formula consists of the following components according to weight percentage:

[0022]

[0023]

[0024] Mix the components according to the formula and put them into a high-speed mixer or a rotary mixer for kneading, then extrude through a granulator with a diameter of 1 mm to obtain wet granules, dry them with a dryer, and then sieve to obtain polyhedral granules.

Embodiment 2

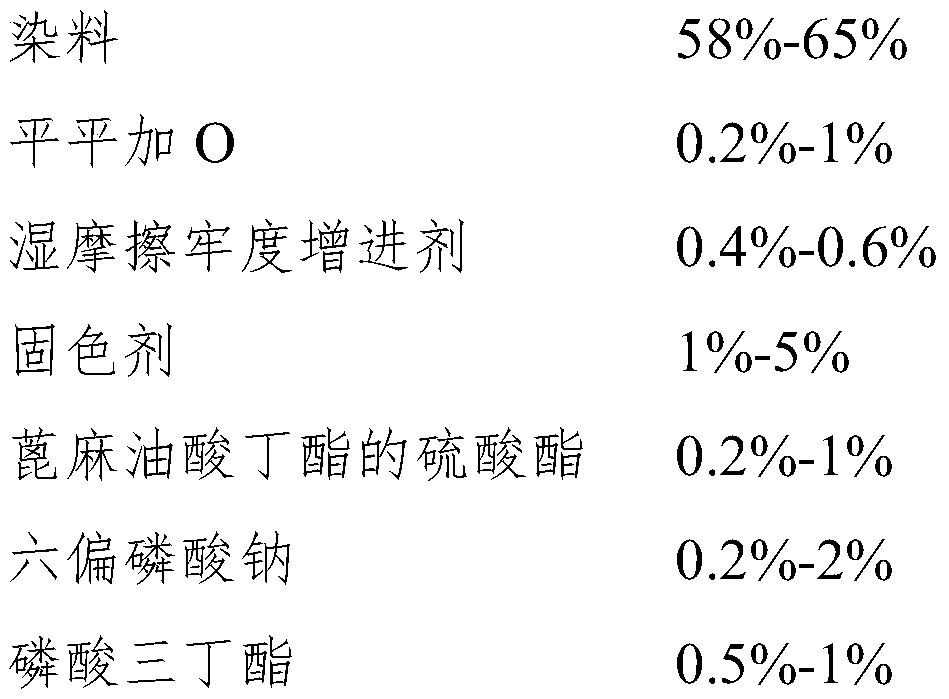

[0026] A reactive dye formula for cotton and linen blending and a preparation method thereof, the formula consists of the following components according to weight percentage:

[0027] The formula consists of the following ingredients by weight percentage:

[0028]

Embodiment 3

[0030] A reactive dye formula for cotton and linen blending and a preparation method thereof, the formula consists of the following components according to weight percentage:

[0031]

[0032]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap