High-precision plate strip production method

A production method and high-precision plate technology, which are applied in the field of strip manufacturing, can solve the problems of complex consumption of rolling strips, large energy consumption, etc., and achieve the effects of saving resources, low energy consumption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

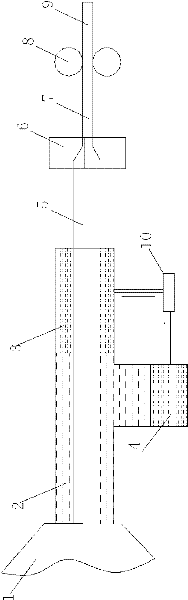

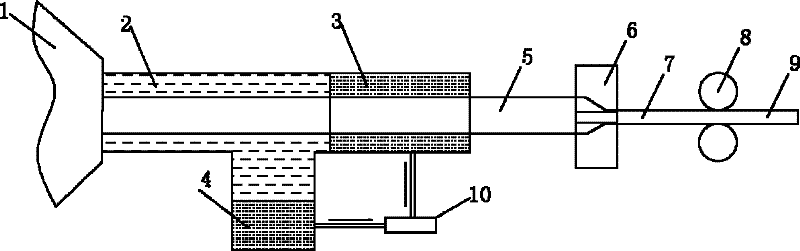

[0015] Such as figure 1 Shown, the production method of high-precision strip comprises the following steps:

[0016] The raw material is extruded out of the round tube 5 by the continuous extrusion production method through the continuous extrusion machine 1, which reduces the steps of forging and rolling, and directly extrudes the thick material into a round tube. The round tube formed in this way has high strength and hardness. ,high density;

[0017] Then, after the round tube 5 is cooled by the cooling liquid 3, it is cut online to form a plate 7 by an online cutting device 6, and the cutting device 6 cuts the round tube 5 and immediately performs online leveling, that is, the cutting device 6 is an online cut flat;

[0018] Then, the plate 7 is passed through a rolling device 8 for on-line finish rolling to form a high-precision strip 9 .

[0019] Wherein, there is an anti-oxidation protective gas 2 between the continuous extruder 1 and the cooling liquid.

[0020] Above

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap