Diepoxide vegetable oil acid acetyl glyceride and synthesis method and application thereof

A technology of vegetable oleic acid acetylglyceride and vegetable oleic acid acetylglycerol, which is applied in the field of plasticizers, can solve the problems of high molecular weight and viscosity of epoxy vegetable oil, poor low-temperature plasticizing performance, high boiling point and flash point, and achieve low cost, Good plasticizing performance at low temperature and high fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Using soybean oil and glycerin as starting materials, soybean oil is a triglyceride of fatty acids. Its fatty acid composition is shown in Table 1. The main component is octadecanoic fatty acid, and other fatty acids within the range of C14-C20:

[0036] Table 1 Fatty acid composition of soybean oil

[0037]

[0038] Synthesizing diepoxy soybean oleic acid acetoglyceride using soybean oil and glycerin as raw materials includes the following steps:

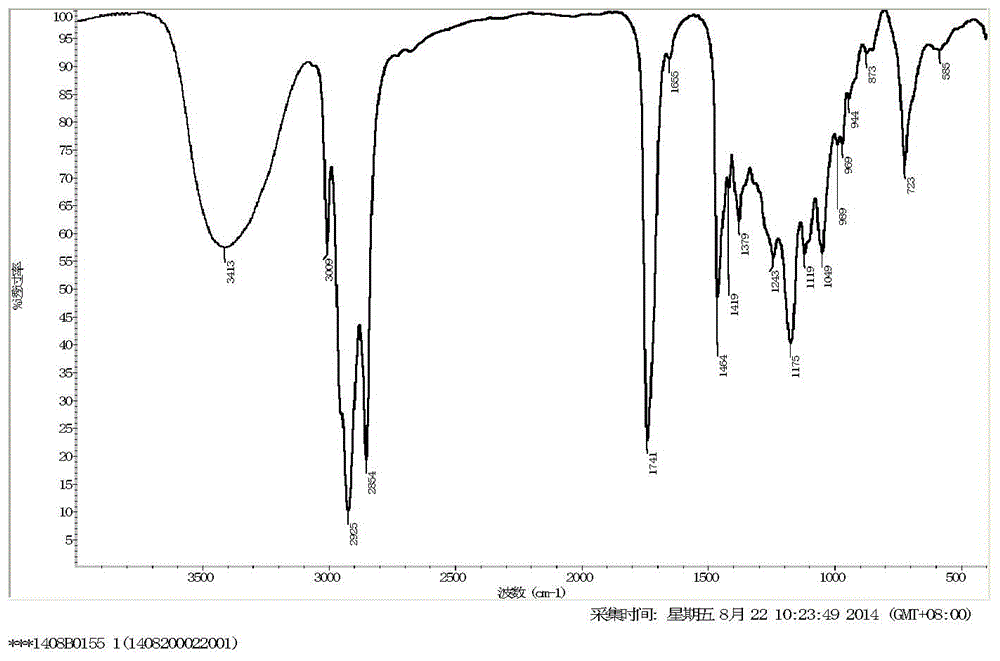

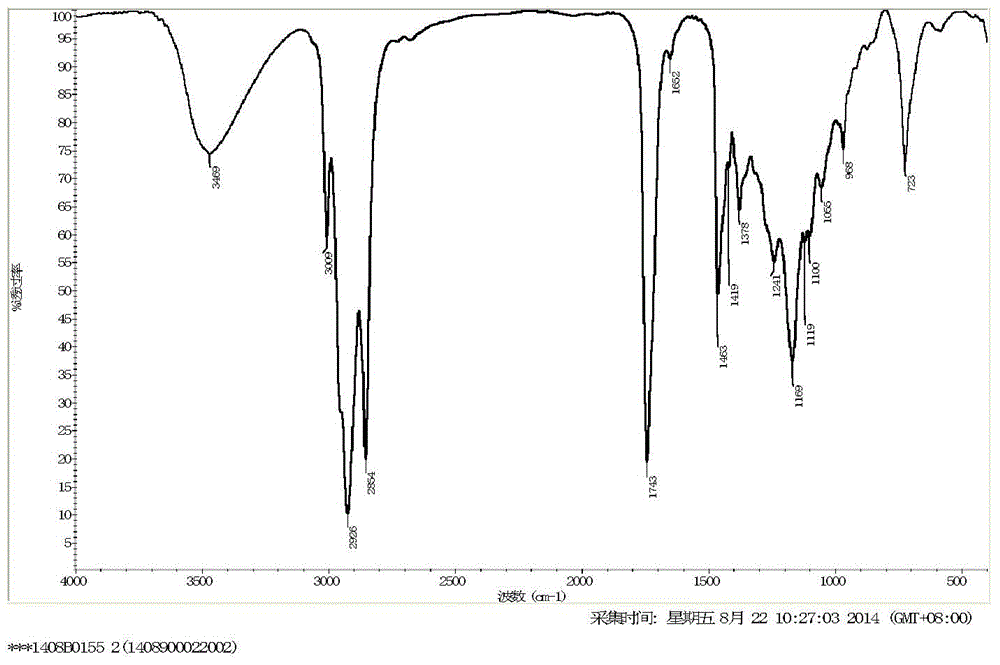

[0039] 1) Transesterification reaction: add 912g of soybean oil and 88g of glycerin to a three-necked flask with a stirrer, thermometer, and reflux condenser, pour in nitrogen gas and stir and heat to 120°C, add 0.05g of calcium oxide, and then heat to 220 Incubate the reaction at °C for 8 hours. During the reaction, the material is taken intermittently, and when 1 part of the sample is miscible with 10 parts of ethanol, the reaction is terminated, and the light yellow oily glycerol disoglyceride is obtained. The infrared test IR (K

Embodiment 2

[0043] Synthesizing diepoxy soybean oleic acid acetoglyceride using soybean oil and glycerin as raw materials includes the following steps:

[0044] 1) Transesterification reaction: Add 897g soybean oil and 88g glycerin to a three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, pour in nitrogen and stir and raise the temperature to 120℃, add 0.05g calcium hydroxide, and raise the temperature to 230℃ Incubate and react for 9 hours. During the reaction process, the material is taken intermittently, and when 1 part of the sample is miscible with 10 parts of ethanol, the reaction is terminated, and the light yellow oily glycerol diglyceride of soybean oil is obtained. After infrared test IR (KBr), it has figure 1 Similar structure to the spectra shown;

[0045] 2) Acetylation reaction: Into a four-necked flask equipped with a stirrer, a thermometer, a water device and a reflux condenser, add 330g of the glyceryl disoyaglyceride obtained in step 1), 150g of ace

Embodiment 3

[0048] Using rapeseed oil as the basic raw material, the rapeseed oil contains 0.4-1.0% arachidic acid, 14-19% oleic acid, 12-24% linoleic acid, 31-35% erucic acid, and 1-10% linolenic acid.

[0049] Using rapeseed oil and glycerin as raw materials to synthesize diepoxy rapeseed oleic acid acetoglyceride, it includes the following steps:

[0050] 1) Transesterification reaction: add 912g of rapeseed oil and 88g of glycerin to a three-necked flask with a stirrer, thermometer, and reflux condenser, pour in nitrogen and stir and heat to 110°C, add 0.05g of sodium hydroxide, and then heat up Incubate the reaction at 250°C for 12 hours. During the reaction, the material is taken intermittently, and when 1 part of the sample is miscible with 10 parts of ethanol, the reaction is terminated, and the light yellow oily two rapeseed glyceride is obtained. After infrared test IR (KBr), it has such figure 1 Similar structure of the spectra shown;

[0051] 2) Acetylation reaction: Into a four-necke

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap