Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Hydroxy group" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hydroxy or hydroxyl group is the entity with the formula OH. It contains oxygen bonded to hydrogen. In organic chemistry, alcohols and carboxylic acids contain hydroxy groups. The anion [OH⁻], called hydroxide, consists of a hydroxyl group.

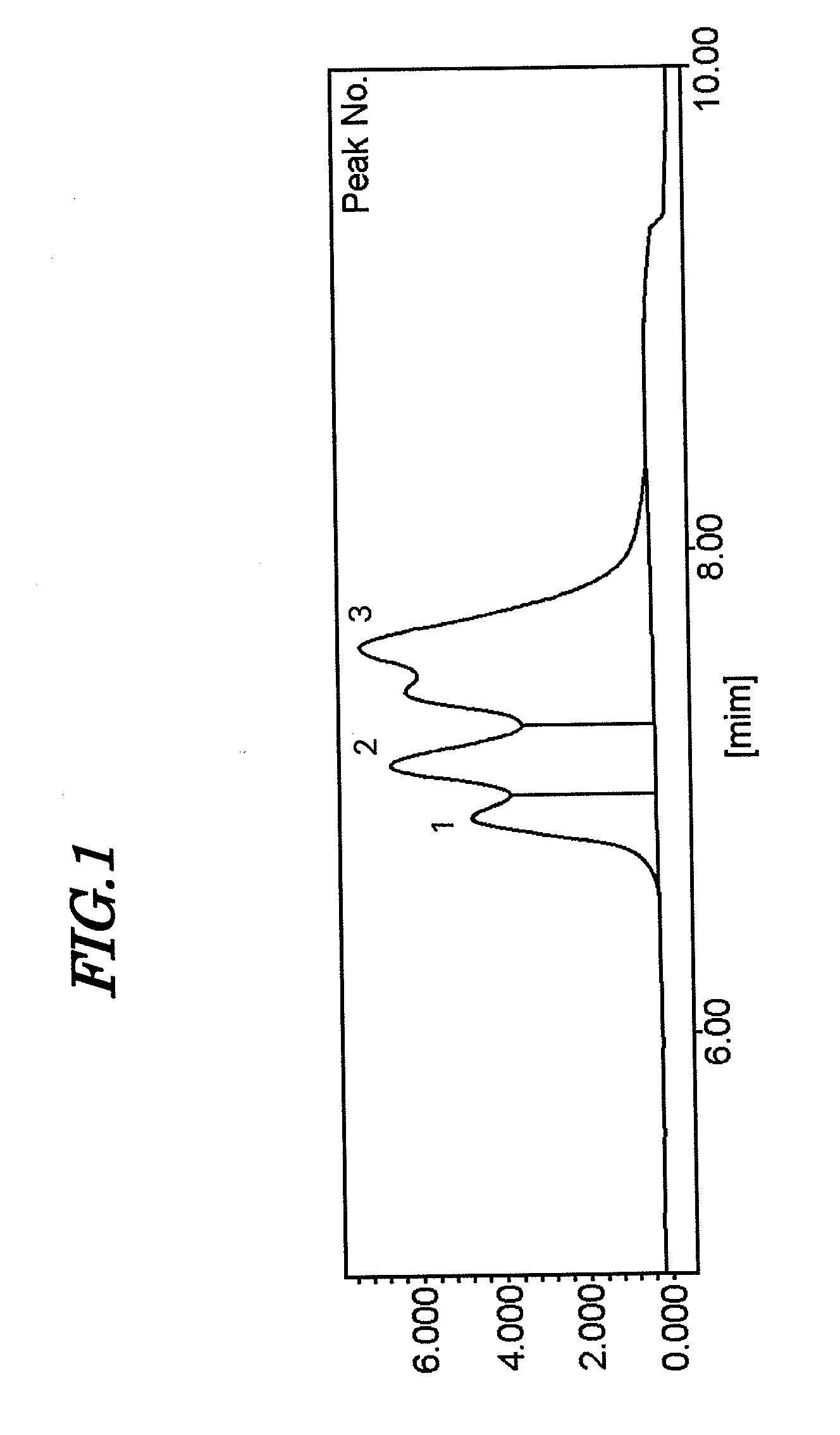

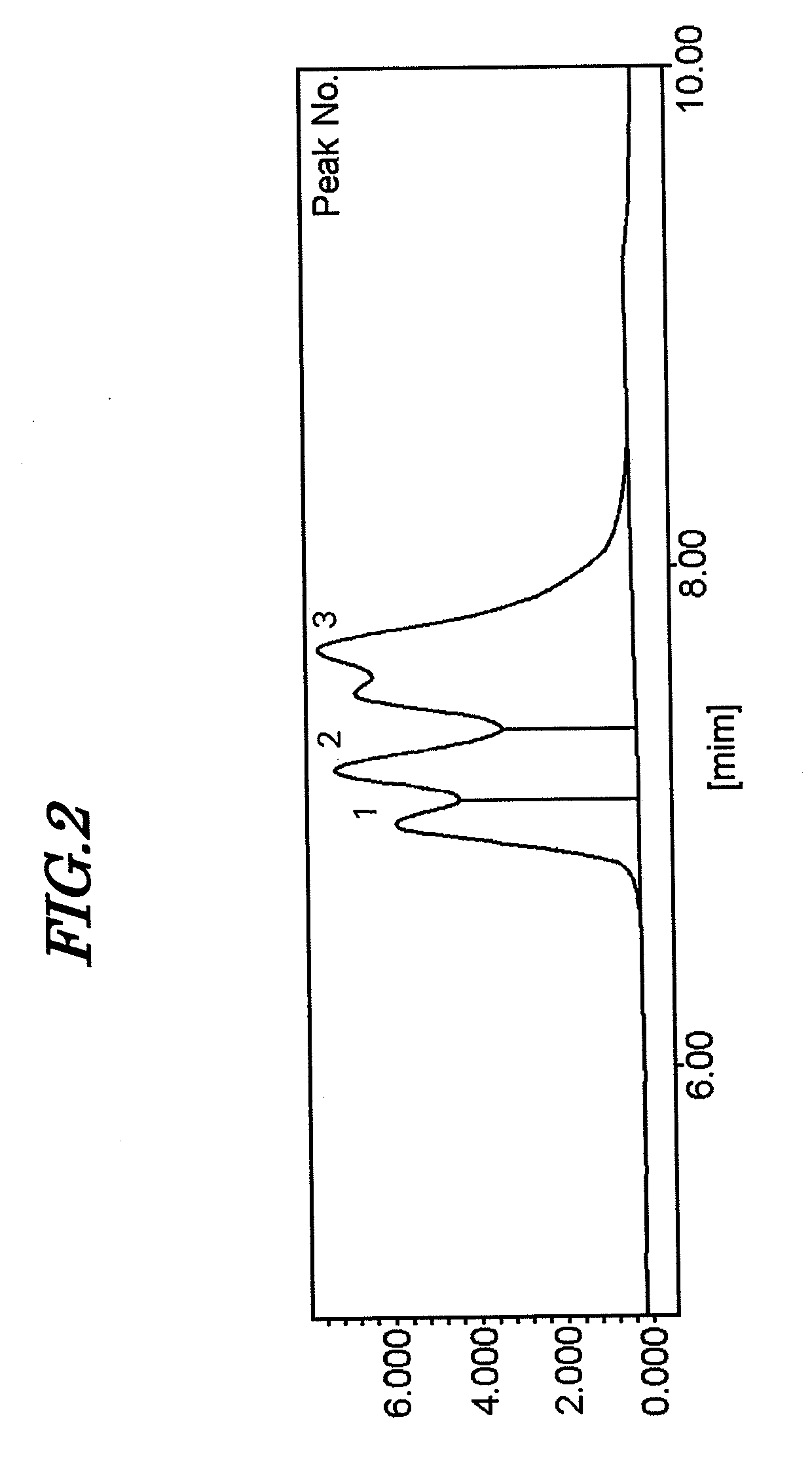

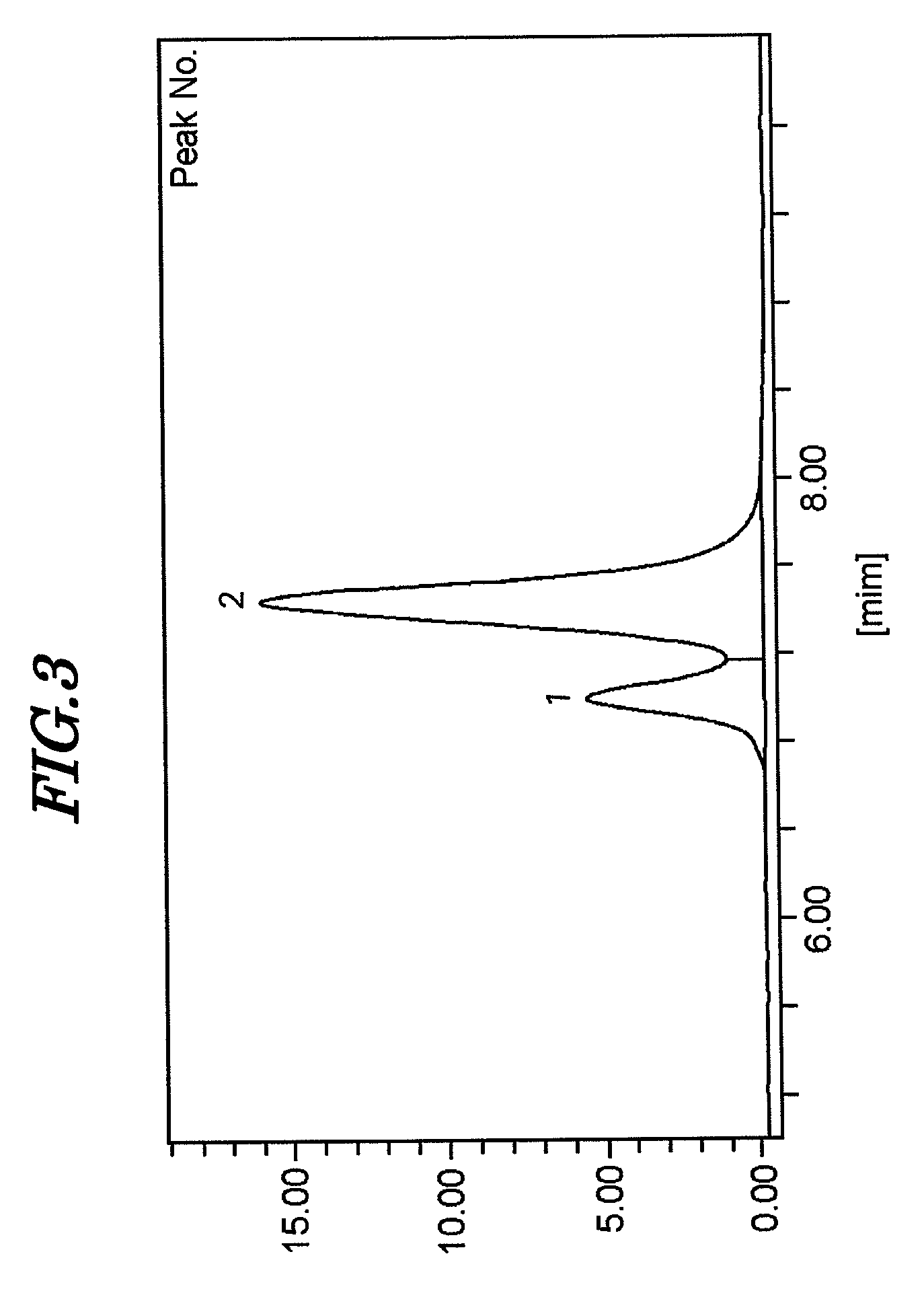

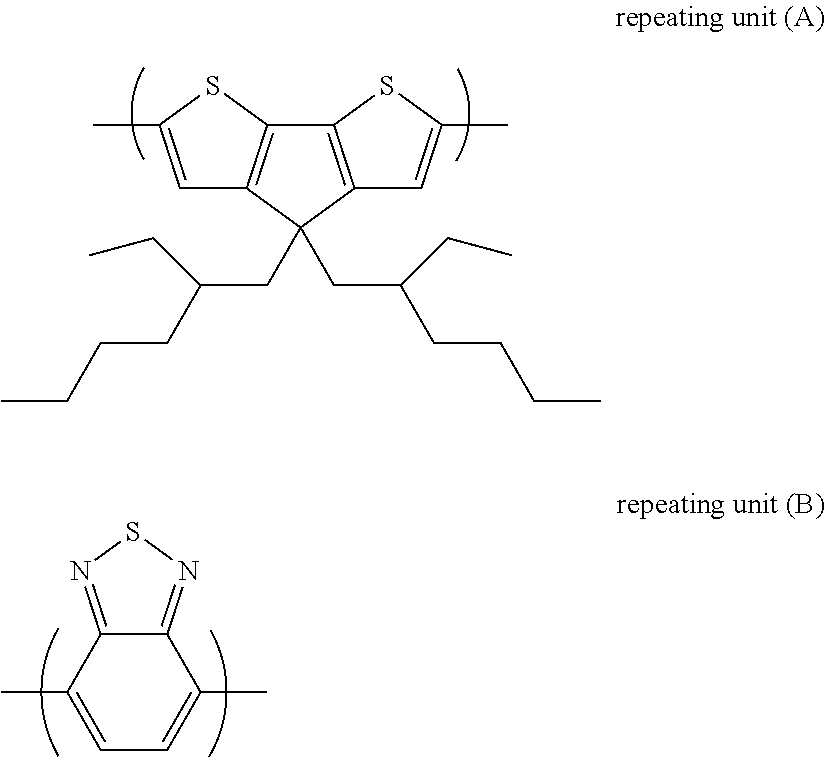

Conjugated diene polymer, method for producing conjugated diene polymer, and conjugated diene polymer composition

Owner:SUMITOMO CHEM CO LTD

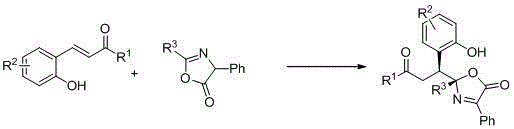

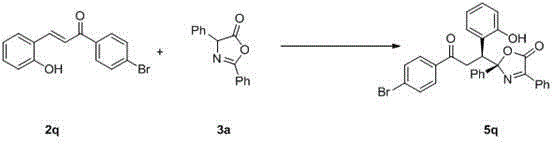

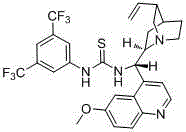

Synthetic method for chiral quaternary carbon oxazolidinone compound

InactiveCN104447604ASimple and fast operationHigh yieldOrganic chemistryThioureaCombinatorial chemistry

Owner:SUZHOU UNIV

Hydrogel based on copolymers containing silicone

The invention relates to a hydrogel that is a copolymer of a polymerizable monomer mixture which contains a) 10-65 mole percent of at least one hydrophobic vinyl monomer of formula (I), where R1 represents hydrogen or methyl, p is an integer ranging from 1 to 8, and in which the hydroxy groups are provided in a protected form, b) 25-70 mole percent of at least one (meth)acrylate, vinyl carbonate, or vinyl carbamate monomer containing silicone, c) 0-25 mole percent of at least one hydrophilic vinyl monomer, and d) 0-10 mole percent of at least one cross-linking agent relative to the total amount of monomers a) to c). The hydroxy groups of the segments formed by monomers a) are provided in a protected or free form in the hydrogel. Said hydrogel can be used for producing contact lenses or intraocular lenses.

Owner:EVONIK ROEHM GMBH

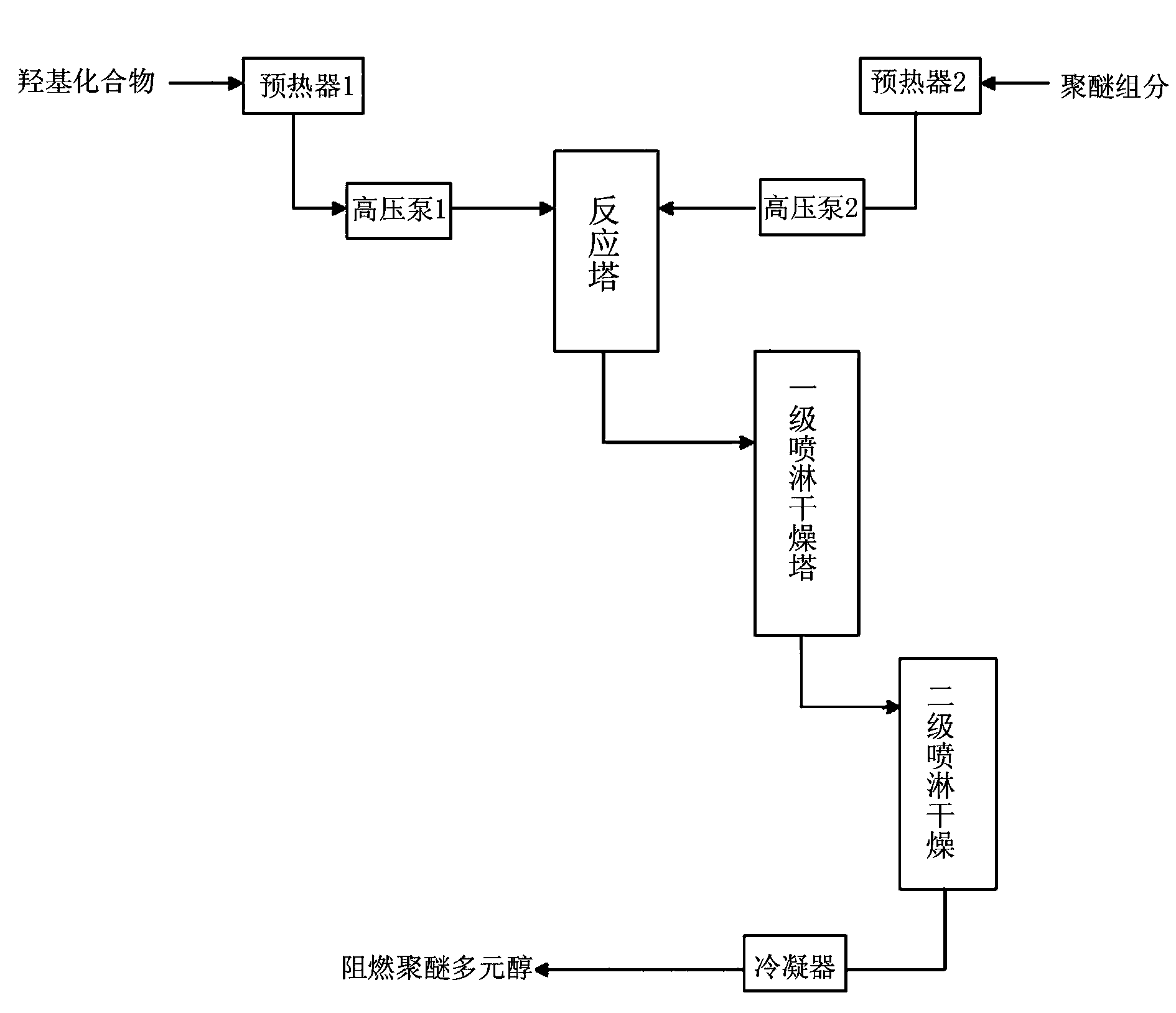

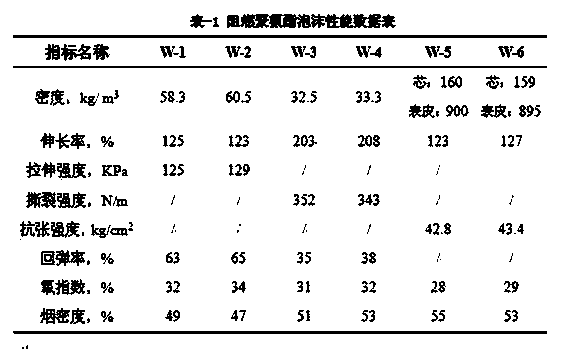

Continuous preparation method of flame retardant polyether polyol

Owner:HONGBAOLI GRP CO LTD

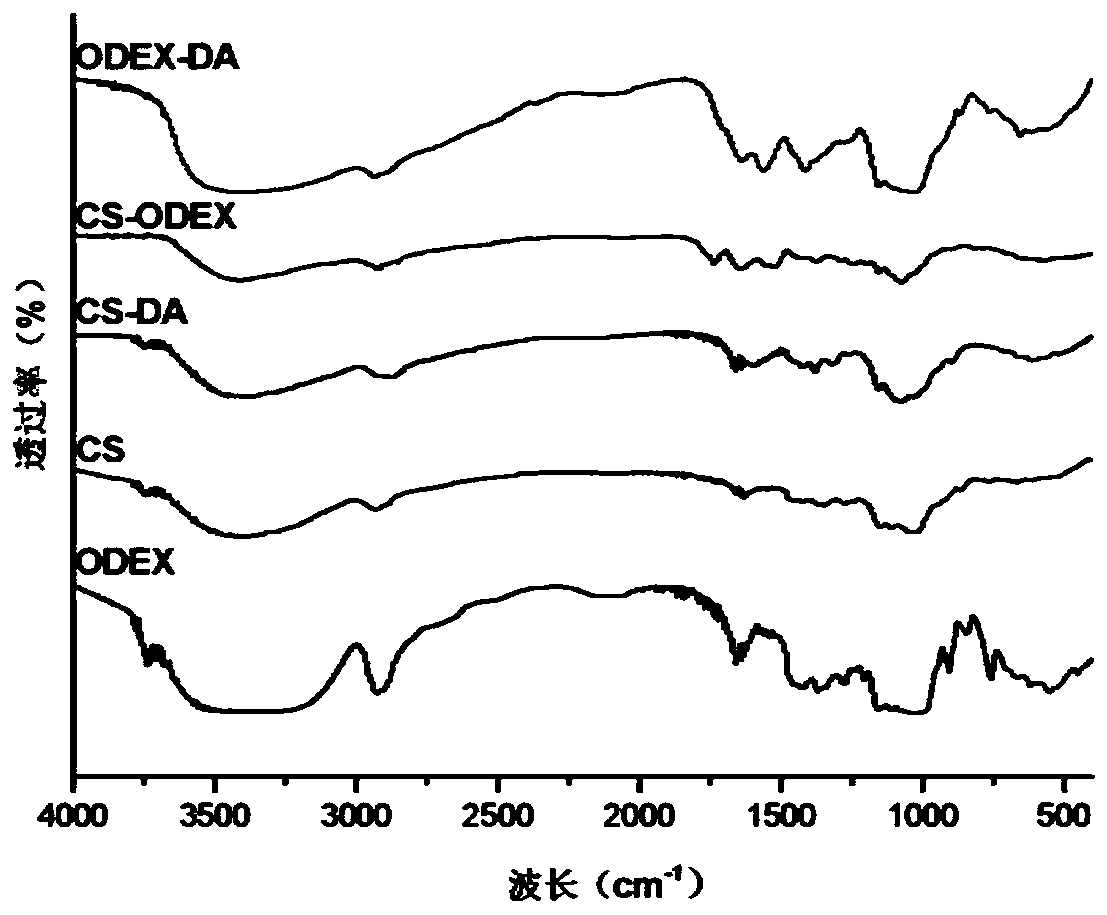

Mussel-imitated underwater high-viscosity hydrogel preparation method

Owner:SOUTHEAST UNIV

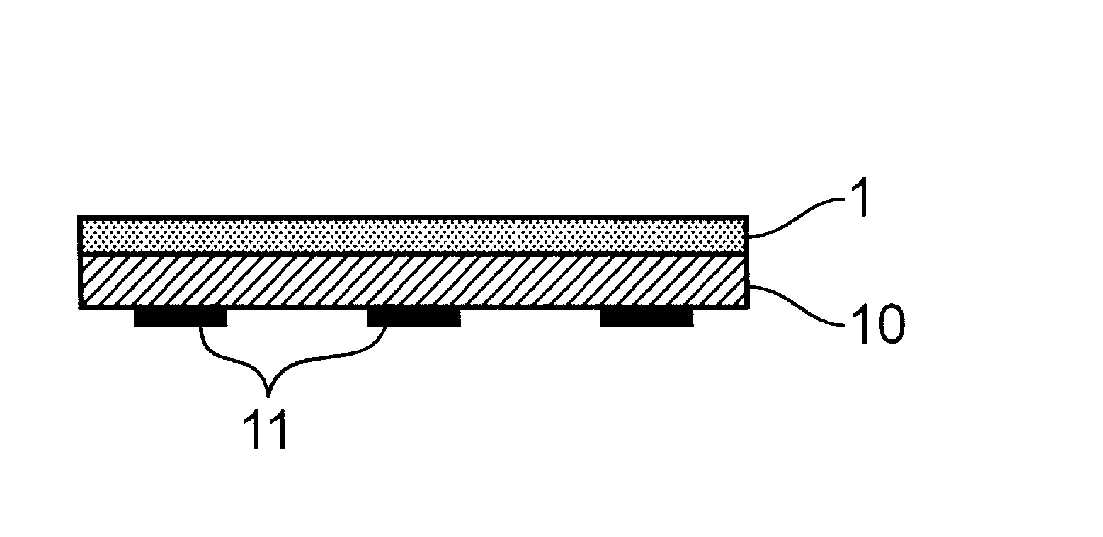

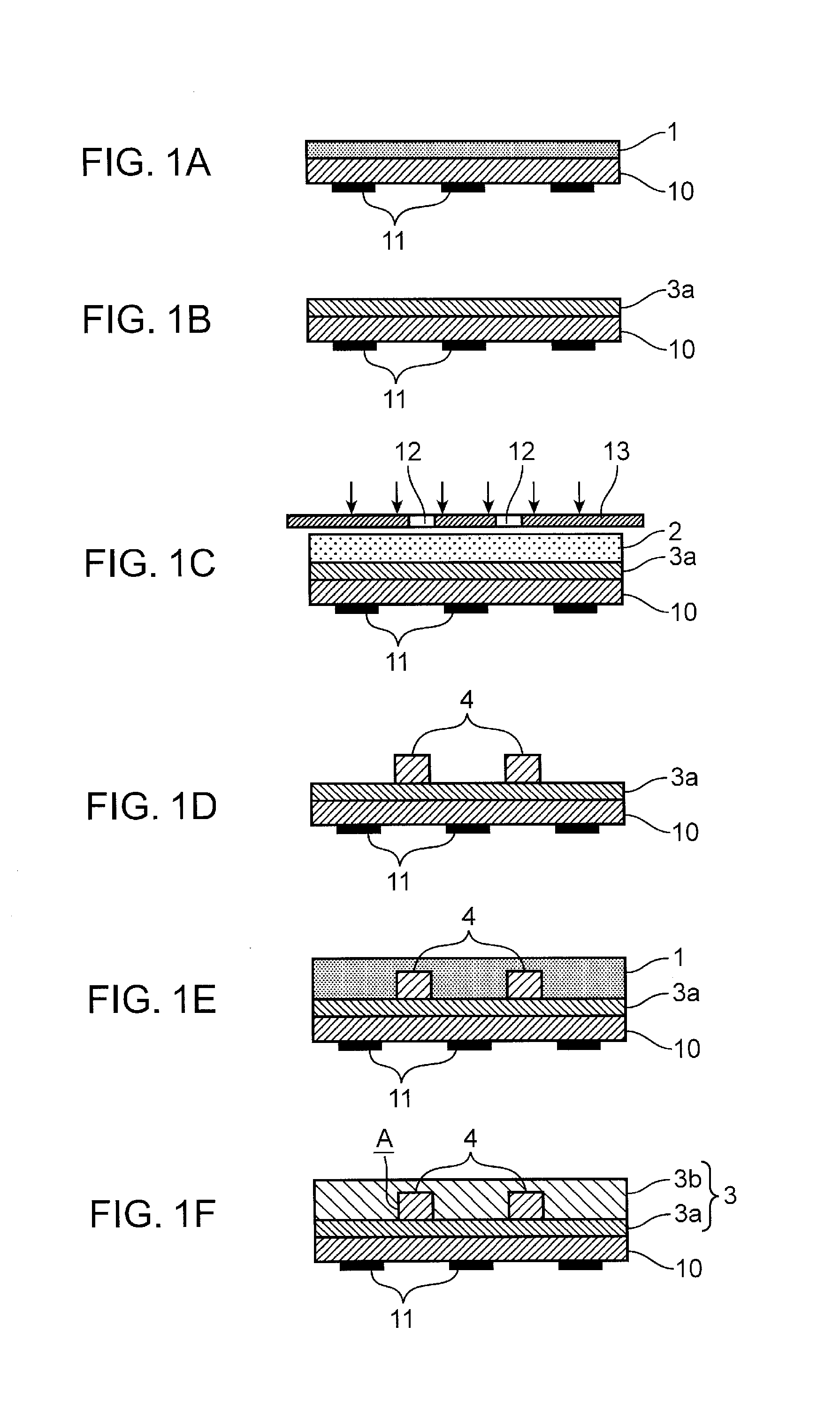

Resin composition for optical waveguide, dry film, optical waveguide, and photoelectric composite wiring board using same

ActiveUS20140004321A1High transparencyLow coefficient of linear expansionDuplicating/marking methodsDecorative surface effectsEpoxyPolymer science

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

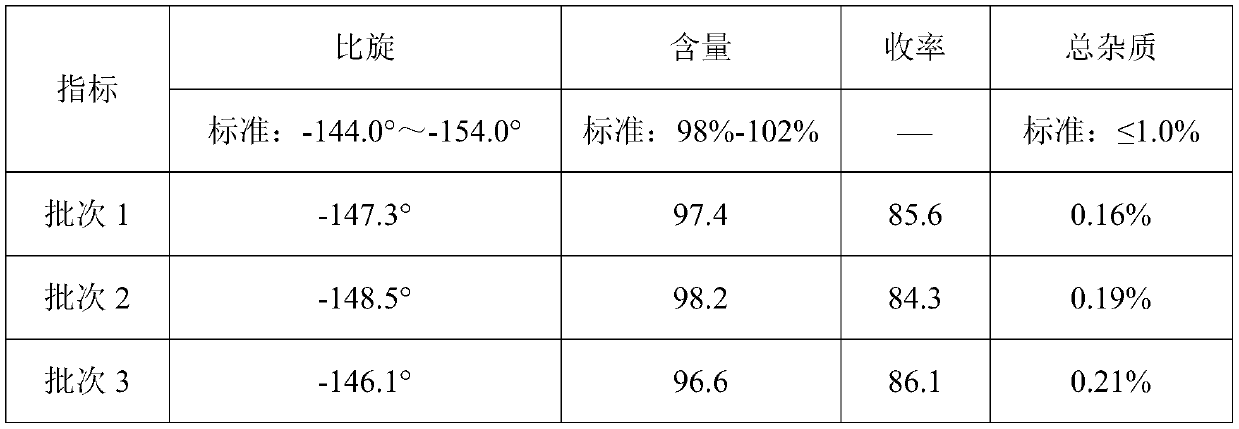

Preparation method of D-p-hydroxyphenylglycine methyl ester

PendingCN111153821AGuaranteed yieldGuaranteed quality indicatorsOrganic compound preparationOrganic chemistry methodsMethanolEster sulfate

Owner:SHANXI WEIQIDA PHARMA IND

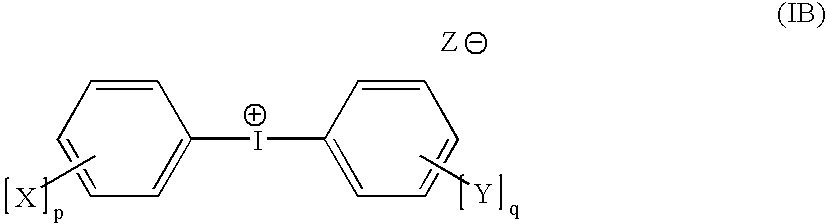

Negative-working imageable elements with improved abrasion resistance

ActiveUS20090233227A1Influence overall viscosityHigh viscosityPhotosensitive materialsDuplicating/marking methodsSilica particleFumed silica

Owner:EASTMAN KODAK CO

Method for forming multilayer coating film

InactiveUS20200010698A1Nice appearanceImprove chip resistanceLiquid surface applicatorsPolyurea/polyurethane coatingsPolymer sciencePolyolefin

Owner:HONDA MOTOR CO LTD +1

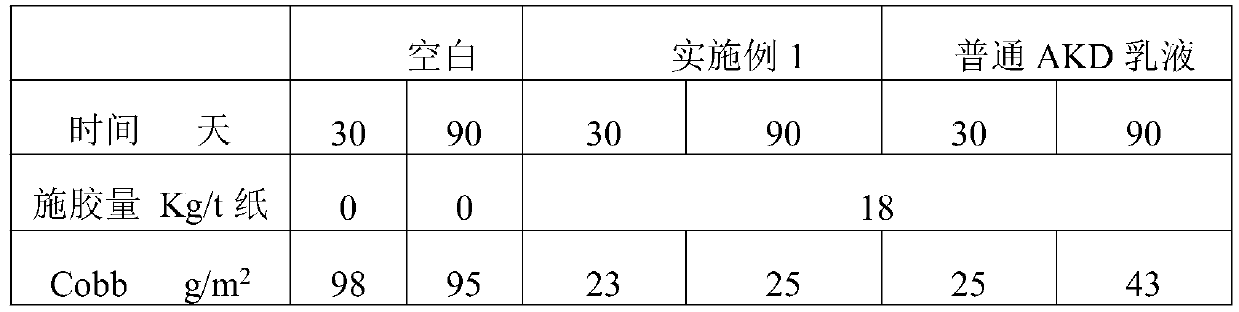

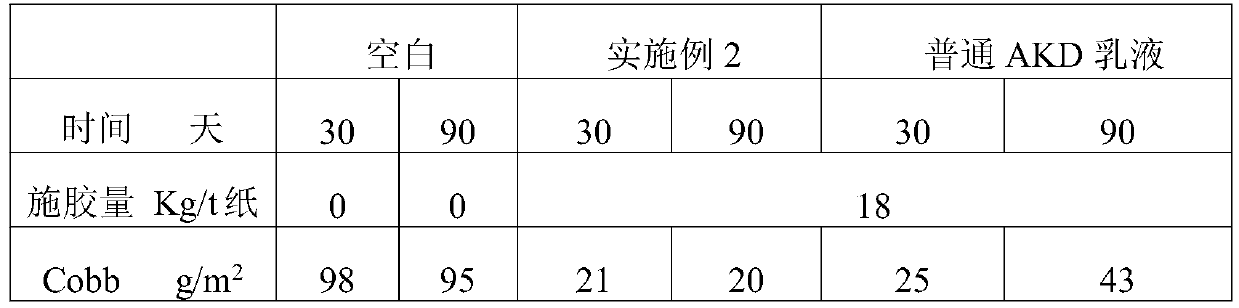

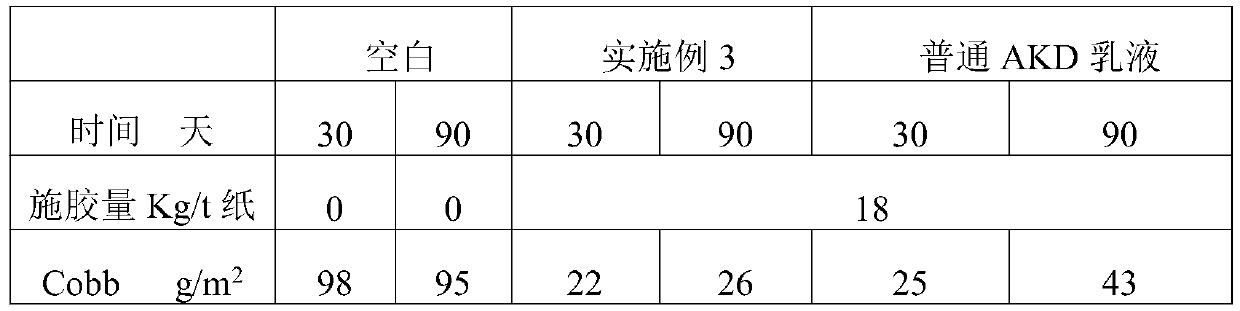

Straight-chain liquid AKD surface sizing agent and preparation method thereof

InactiveCN110983856ALimit hydrolysisLimit migratory propensityWater-repelling agents additionFiberPolymer science

Owner:JINING MING SHENG NEW MATERIALS CO LTD

Fiber coatings with low modulus and high critical stress

Fiber coatings with low Young's modulus, high tear strength, and / or high critical stress are achieved with coating compositions that include an oligomeric material formed from an isocyanate, a hydroxyacrylate compound and a polyol. The oligomeric material includes a polyether urethane acrylate and a di-adduct compound. The reaction mixture used to form the oligomeric material includes a molar ratio of isocyanate:hydroxy acrylate:polyol of n:m:p, where when p is 2, n is in the range from 3.0 to 5.0 and m is in the range from 1.50n-3 to 2.50n-5. Control of the n:m:p ratio leads to compositionsthat, when cured, provide coatings and cured products having high critical stress, high tear strength, and a high ratio of tear strength to Young's modulus.

Owner:CORNING INC

Environment-friendly plastic material and preparation method thereof

The invention discloses an environment-friendly plastic material and a preparation method thereof. The preparation method comprises the following steps that 1, ball milling is performed on calcium sulfate and magnesium oxide through a ball mill, the ball milling time is 3-5 h, and the ratio of grinding media to the materials is 20:1-30:1; 2, 12-20 parts of polyamide-1010, 5-10 parts of polycarbonate, 4-9 parts of alkyd resin, 4-8 parts of polyvinyl alcohol, 3-8 parts of calcium sulfate, 4-10 parts of magnesium oxide, 2-6 parts of polytrimethylene terephthalate, 3-8 parts of tetrafluoroethylene-hexafluoropropylene copolymer, 2-6 parts of polybutyl methacrylate and 4-10 parts of polyparahydroxybenzoic acid are weighed by weight, all the components are extruded inside a double-screw extruder, and the extruded components are the environment-friendly plastic material. The obtained plastic material effectively overcomes the defects that the tensile strength and the elongation at break of the conventional plastic material are low, and the mechanical performance of the plastic material is improved.

Owner:SUZHOU SHURUI ENVIRONMENTAL PROTECTION TECH CO LTD

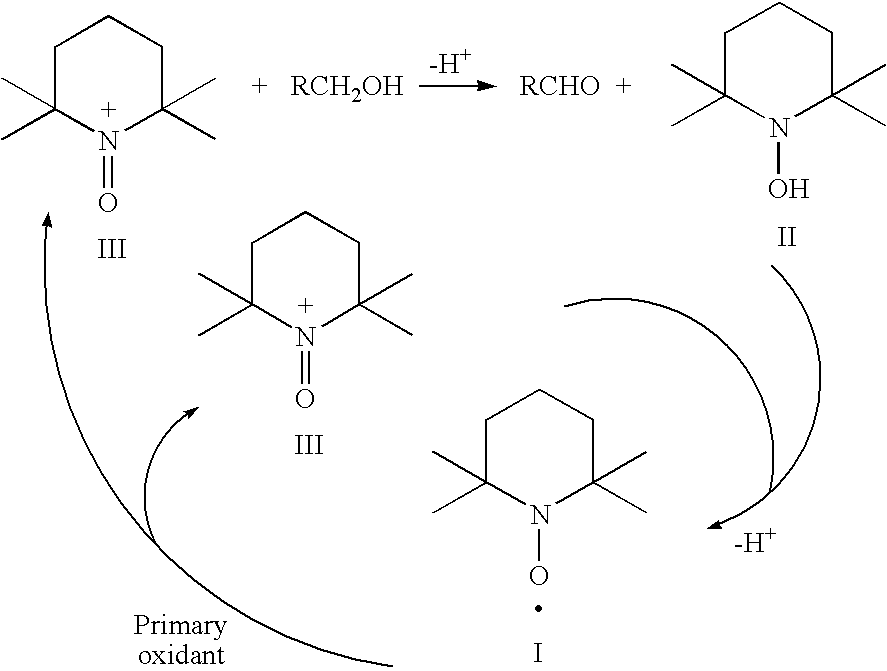

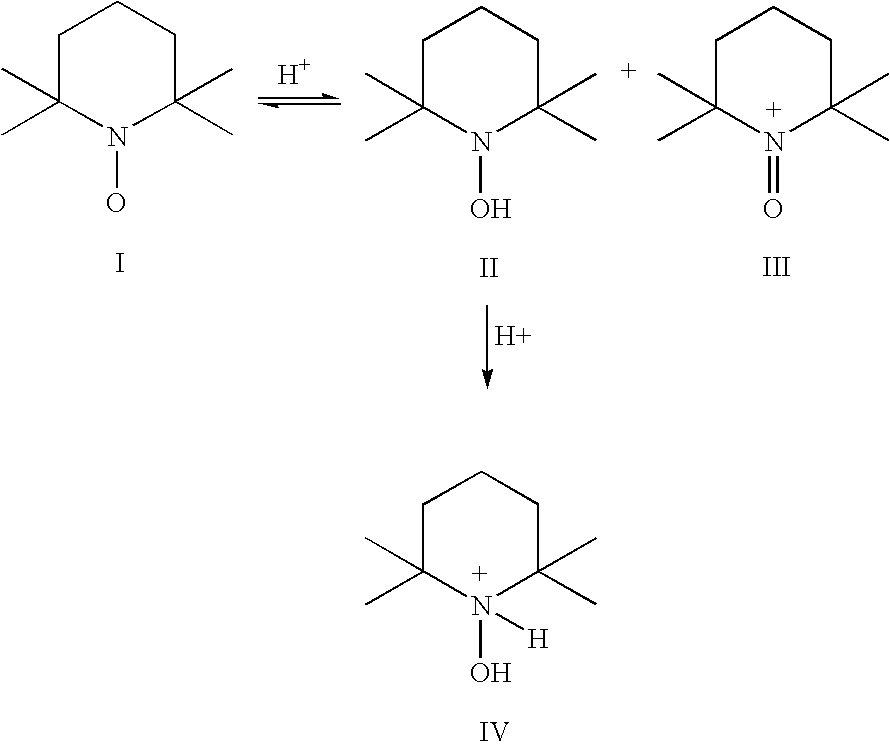

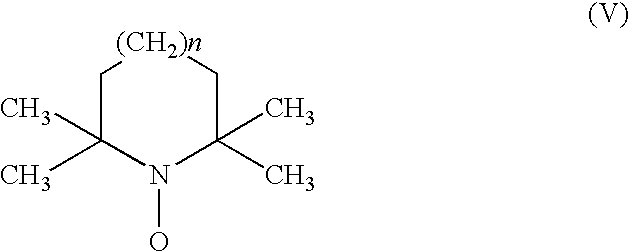

Process for the separation of organic hydroxylamine and nitrosonium compounds and its use in the oxidation of hydroxy compounds

InactiveUS20050154233A1Easy to recycleOrganic compounds purification/separation/stabilisationCarbonyl group formation/introductionProtonationHydroxylamine compound

Owner:SCA HYGIENE PROD AB

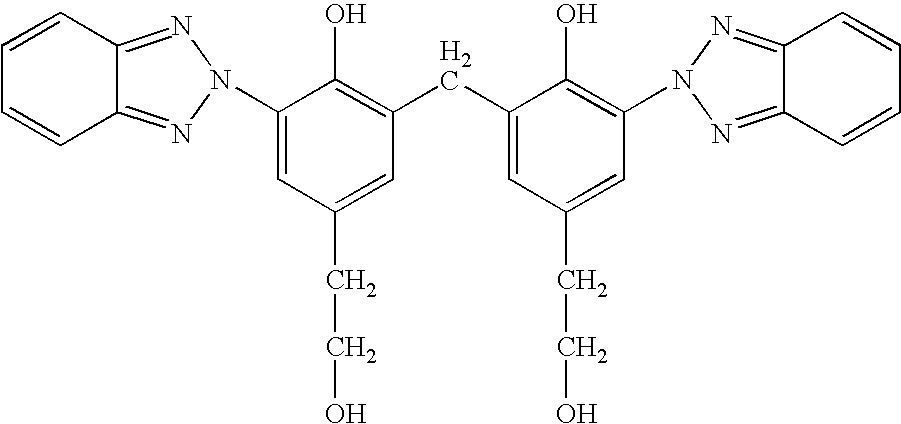

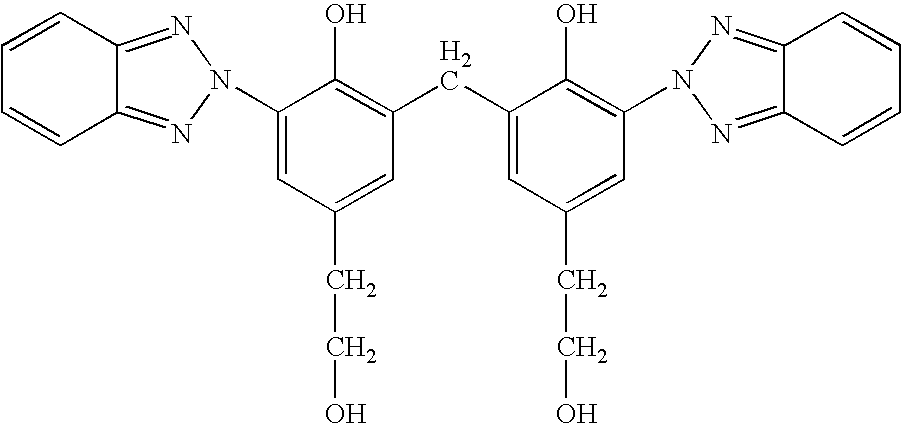

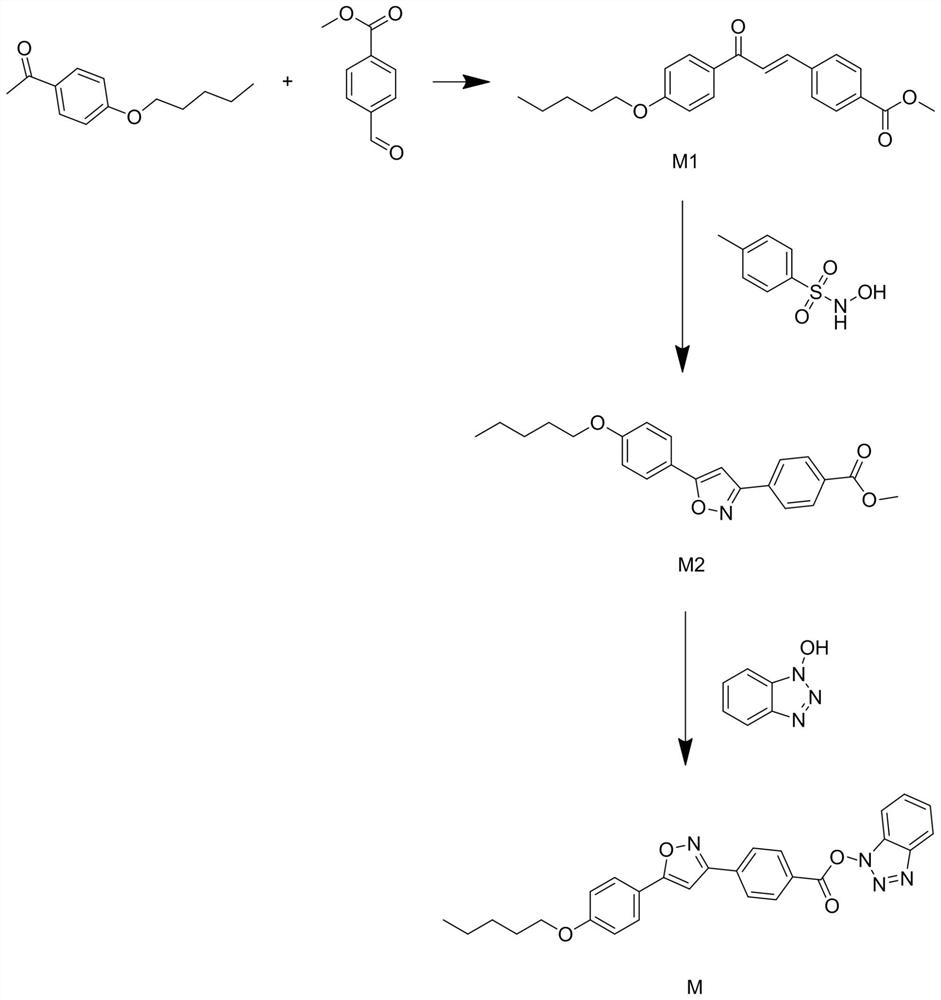

Aqueous emulsion of ultraviolet-absorbing resin and emulsion resin composition

InactiveUS20060155015A1Improve compatibilityAvoid bleedingOrganic chemistryOrganic dyesEmulsionBoiling point

An aqueous ultraviolet-absorbing resin emulsion, and an aqueous resin emulsion composition containing the emulsion is provided, wherein the emulsion is excellent in compatibility with a synthetic resin and light resistance. Also, the emulsion improves stability in blending with an aqueous emulsion of the synthetic resin, and prevents bleed out of the ultraviolet-absorbing resin on the surface of a coating film. Further, the aqueous ultraviolet-absorbing resin emulsion imparts excellent alkali or solvent resistance to a synthetic resin poor in alkali or solvent resistance. More specifically, an aqueous resin emulsion composition comprising (I) an aqueous ultraviolet-absorbing resin emulsion and (II) an other aqueous resin emulsion is provided, wherein the emulsion (I) is obtained by urethanizing (A) a polyol component having an ultraviolet-absorbing group {e.g., 1,1-bis[3-(2H-benzotriazol-2-yl)-4-hydroxy-benzeneethanol]methane}, (B) a polyol if necessary, (C) an alkyl or aryl dialkanolamine compound, and (D) an organic polyisocyanate in (E) an organic solvent, diluting the reaction mixture with (F) an organic solvent having a boiling point lower than 100° C. to give a resin solution, neutralizing the resin solution with (G) a neutralizing agent, and dispersing the resultant in water.

Owner:DAICEL CHEM IND LTD

Preparation method of pyroxsulam intermediate

ActiveCN113292487AAvoid Polymerization Side ReactionsGuaranteed purityOrganic compound preparationCarboxylic acid esters preparationAcyl groupDouble bond

The invention discloses a preparation method of a pyroxsulam intermediate, which comprises the following steps: (1) carrying out condensation reaction on 4-alkoxy-1,1,1-trifluoro-3-buten-2-one and phosphonoacetic acid trialkyl ester in an alcohol solvent in the presence of sodium alcoholate to generate an intermediate 3-trifluoromethyl-5,5-dialkoxy pentenoic acid alkyl ester and an isomer of the intermediate 3-trifluoromethyl-5,5-dialkoxy pentenoic acid alkyl ester; and (2) carrying out cyclization reaction on the intermediate generated in the step (1) and ammonium acetate in the presence of a polymerization inhibition catalyst to generate 2-hydroxy-4-trifluoromethylpyridine. According to the method disclosed by the invention, hydroquinone and other polymerization inhibition catalysts are added in the cyclization process, so that polymerization side reaction of a condensation intermediate containing double bonds can be avoided, and the reaction yield and the product purity of the cyclization reaction are ensured. Meanwhile, the 4-butoxy-1,1,1-trifluoro-3-buten-2-one and the phosphonoacetic acid trimethyl ester are adopted as the condensation reaction raw materials, so that not only can higher condensation reaction yield be obtained, but also the cost is lower, and the safety is higher.

Owner:JIANGSU AGROCHEM LAB CO LTD

Colored resin composition, colored film, decorative substrate and touch panel

InactiveUS20180039176A1Improve reliabilityImprove heat resistanceSolid-state devicesSemiconductor/solid-state device manufacturingPolymer scienceDisplay device

A colored resin composition is disclosed including a polyimide resin having a specified structure to achieve remarkable heat resistance and enabling the formation of a colored film which is excellent in reliability because a coloring material is highly dispersed and stabilized therein. A colored resin composition is disclosed including (A) an alkali-soluble polyimide resin having a structural unit containing a phenolic hydroxyl group, a sulfonic acid group or a thiol group, (B) a coloring material, (C) a polymeric dispersant, and (D) an organic solvent. A patterned colored layer obtained from the composition of the present invention is useful for a decorative substrate, a touch panel, an organic EL display device and the like.

Owner:TORAY IND INC

Reactive compound

Owner:SUMITOMO CHEM CO LTD

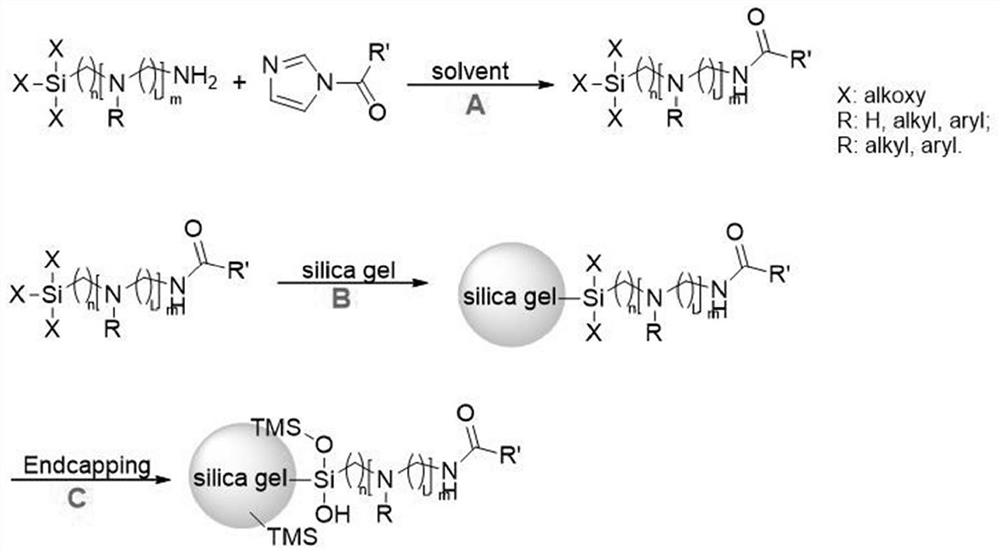

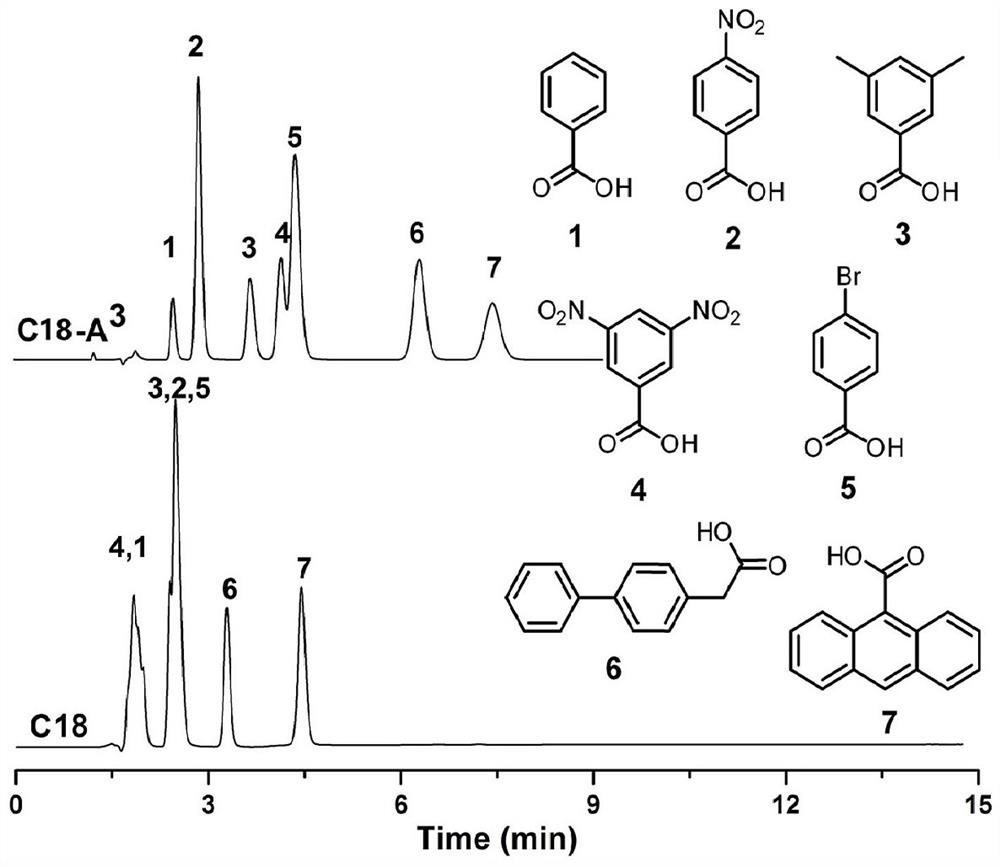

Preparation method of mixed-mode liquid chromatography filler based on single selector

ActiveCN113042017AResponse specificityHomogeneous surface chemistryOther chemical processesStationary phaseFluid phase

Owner:江苏汉德科技有限公司

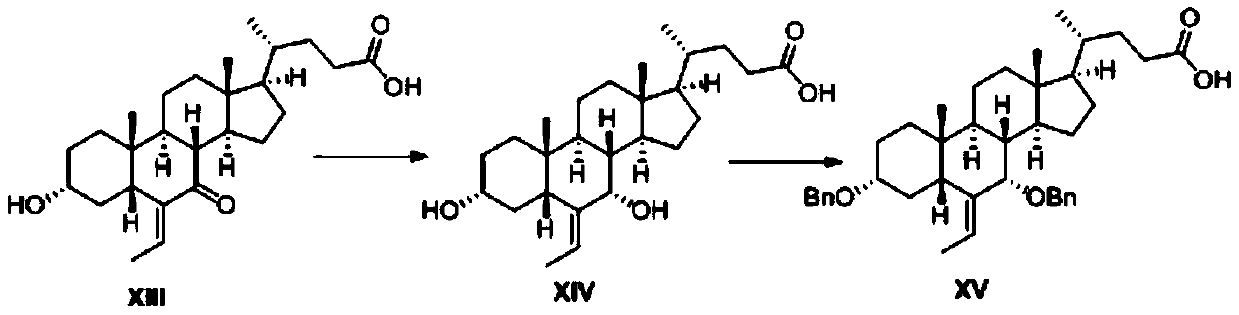

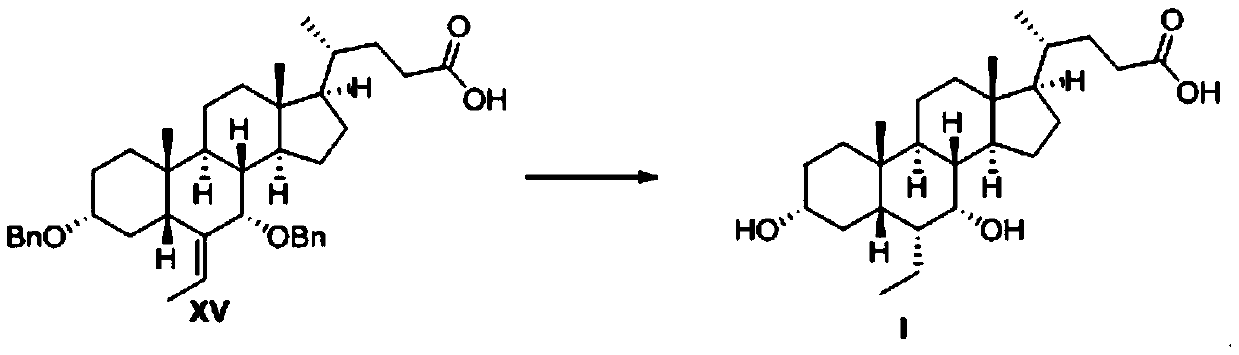

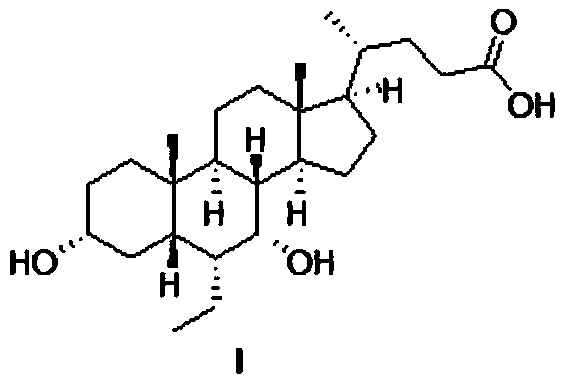

Method for preparing obeticholic acid intermediate and obeticholic acid thereby

ActiveCN110938106AReduce the difficulty of refiningEasy to track reactionsSteroidsCholic acidUv absorbance

Owner:ZENJI RES LAB

Composition and method for inhibiting corrosion and scale

ActiveCN111051251ASpecific water treatment objectivesScale removal and water softeningPolyaspartic acidCarboxylic acid

A composition and a method of inhibiting corrosion, white rust, and scale formation on components in a water system. The composition preferably comprises an amino-acid based polymer (most preferably apotyaspartic acid or a salt thereof), hydroxyphosphonoacetic acid, and a second phosphonic acid (preferably a phosphonocarboxylic acid), and does not require the use of regulated metals. The composition is effective even in the presence of biocides. A preferred method of inhibiting white rust comprises adding an amino-acid based polymer or hydroxyphosphonoacetic acid or both to the water system.A preferred method of inhibiting corrosion, white rust, and scale formation comprises adding an amino-acid based polymer, hydroxyphosphonoacetic acid, and a phosphonocarboxylic acid to the water system. Preferably the active concentrations are at least 3 ppm each of the amino-acid based polymer and hydroxyphosphonoacetic acid when added to a volume of water in the water system.

Owner:NCH CORP

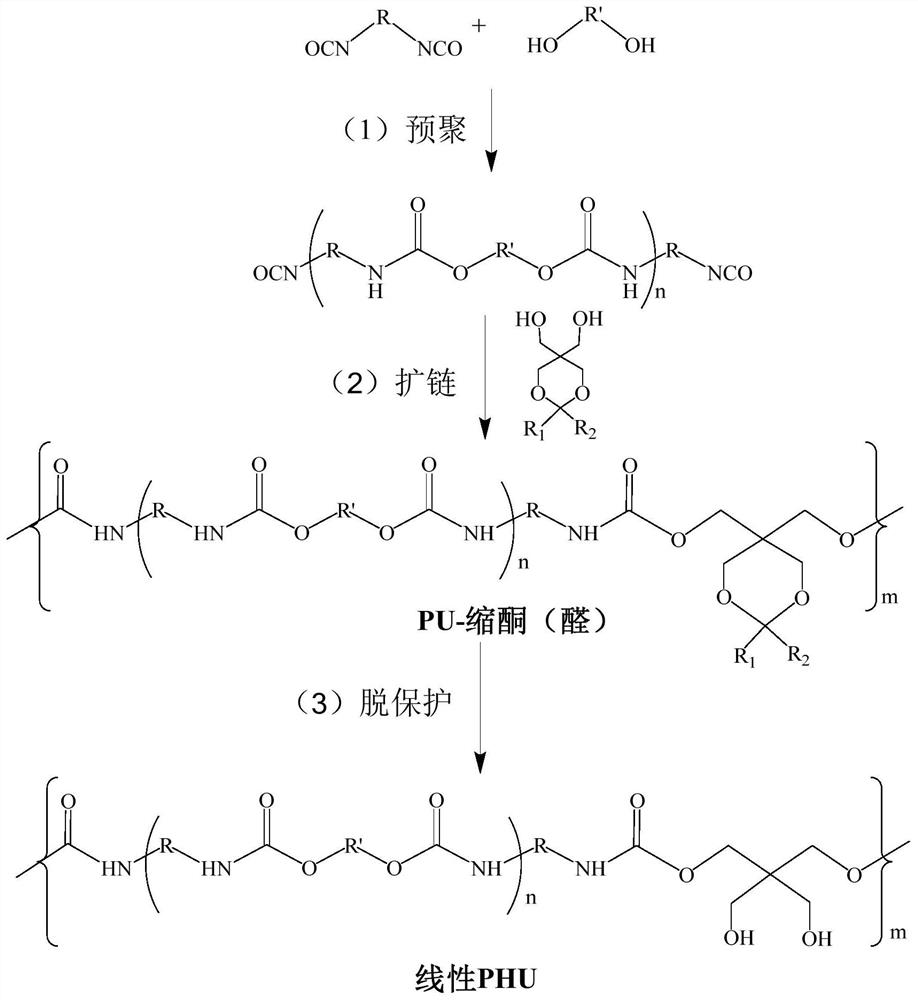

Preparation method of hydroxyl polyurethane

Owner:SHANGHAI JIAO TONG UNIV

Synthesis method of micafungin side chain intermediate

Owner:大桐制药(中国)有限责任公司

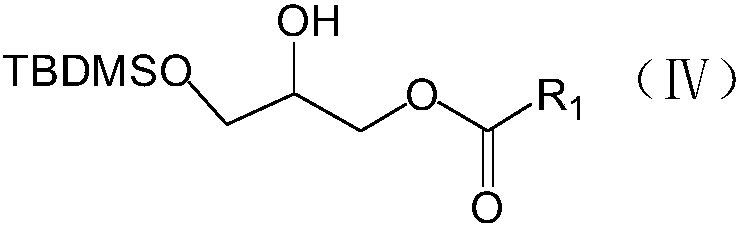

Preparation method of phosphatidylglycerol monosodium salt containing two different side chains

PendingCN111057100AHigh purityHigh yieldPhosphatide foodstuff compositionsPhosphorus organic compoundsSide chainPhospholipid

Owner:HEFEI BOSIKC PHARMTECH CO LTD

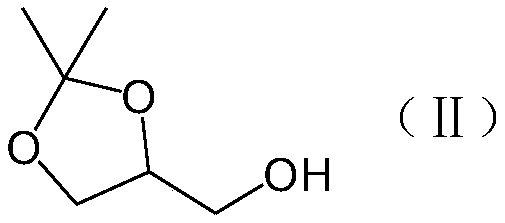

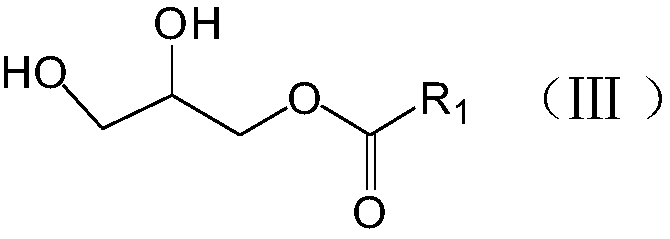

Synthesis method of 2-chloro-1-(2, 2-dimethyl-4H-benzo [1, 3] dioxin-6-yl) ethanone

Owner:安徽有吉医药科技有限公司

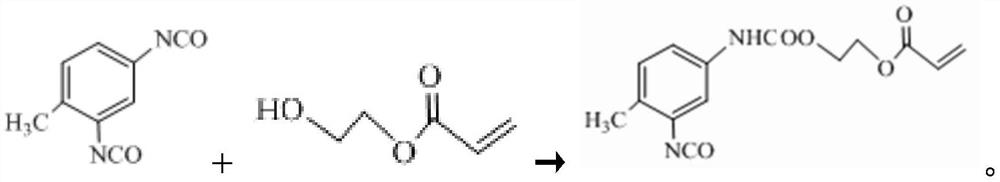

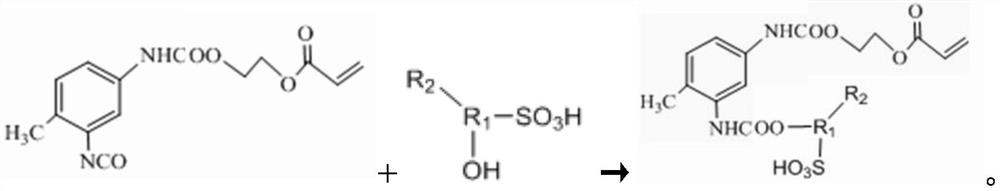

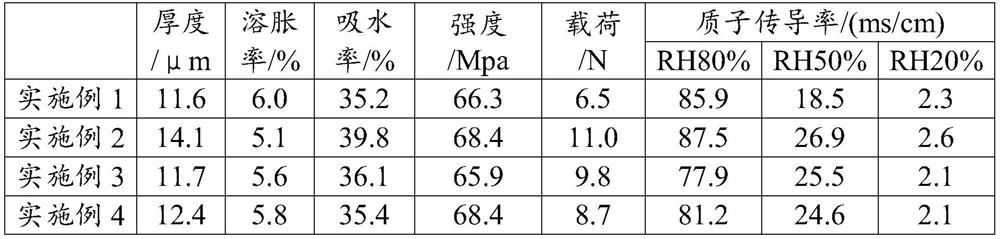

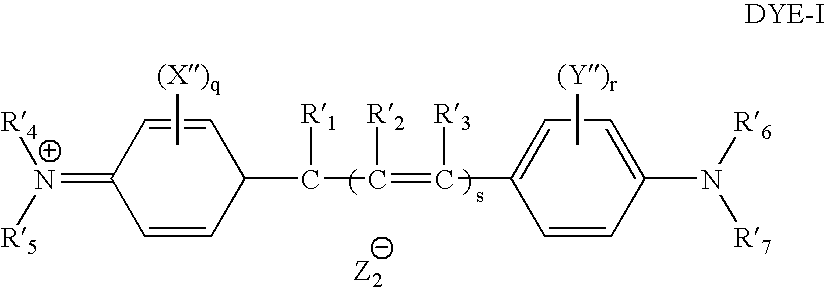

Proton exchange membrane and preparation method thereof

PendingCN114725459AReduce manufacturing costSolve the problem of high energy consumptionFinal product manufactureFuel cellsCombinatorial chemistryPhotoinitiator

Owner:SHENZHEN GENERAL HYDROGEN ENERGY TECH CORP LTD

Random Copolymer Compound, Terminal-Modified Polymer Compound, and Resin Composition Including Said Compounds

PendingUS20210395464A1Well formedMaintain good propertiesNon-macromolecular adhesive additivesPolyether adhesivesPolymer scienceEther

A random copolymer compound of (A) a polyphenylene ether resin having phenolic hydroxy groups at both ends, (B) an aliphatic polymer having alcoholic hydroxy groups at both ends, and (C) an acid dichloride compound that is a binder is disclosed, wherein the number of mol a of the (A) polyphenylene ether resin, the number of mol b of the (B) aliphatic polymer, and the number of mol c of the (C) acid dichloride compound that is a binder satisfies the relationship (a+b)>c.

Owner:NIPPON KAYAKU CO LTD

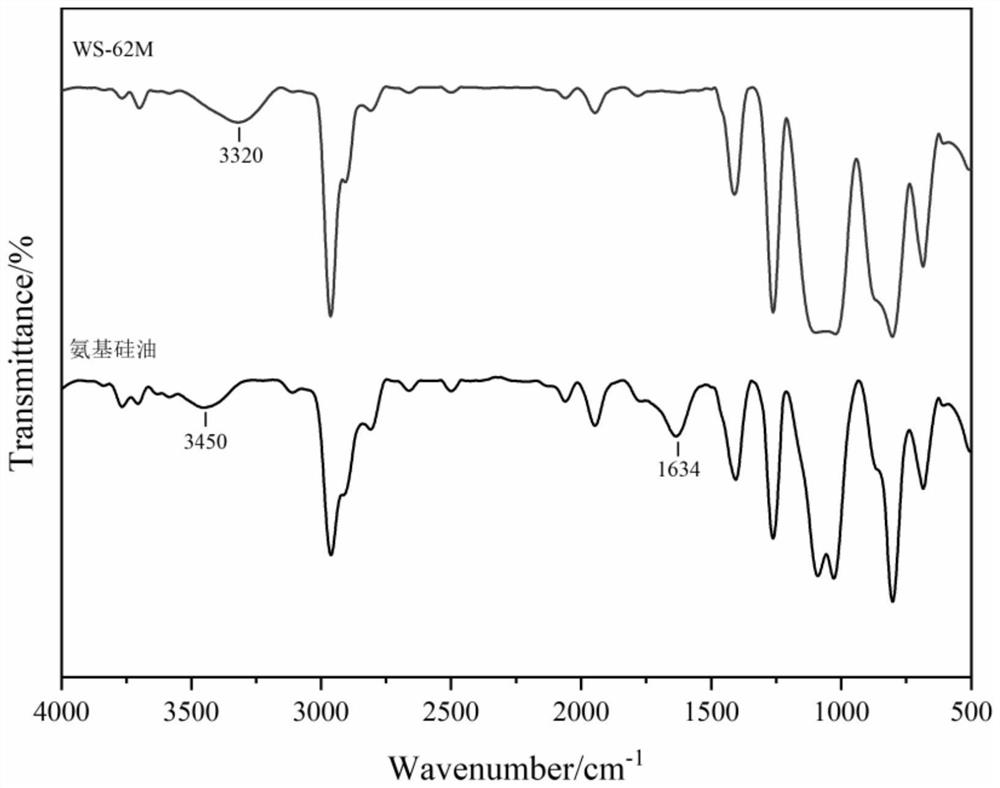

Side chain type amino silicone oil emulsion and preparation method thereof

Owner:EAST CHINA UNIV OF SCI & TECH

Metal spray cleaning agent

InactiveCN111041500AResidue reductionReduce alkalinityMeth-Sodium phosphates

Owner:南京明仁光电科技有限公司

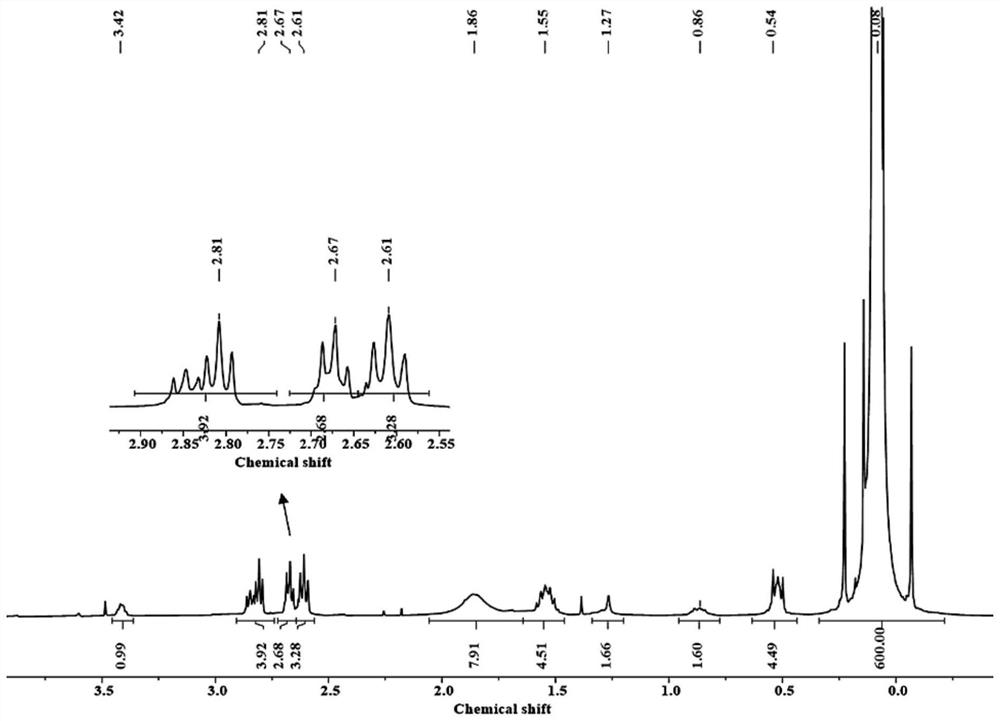

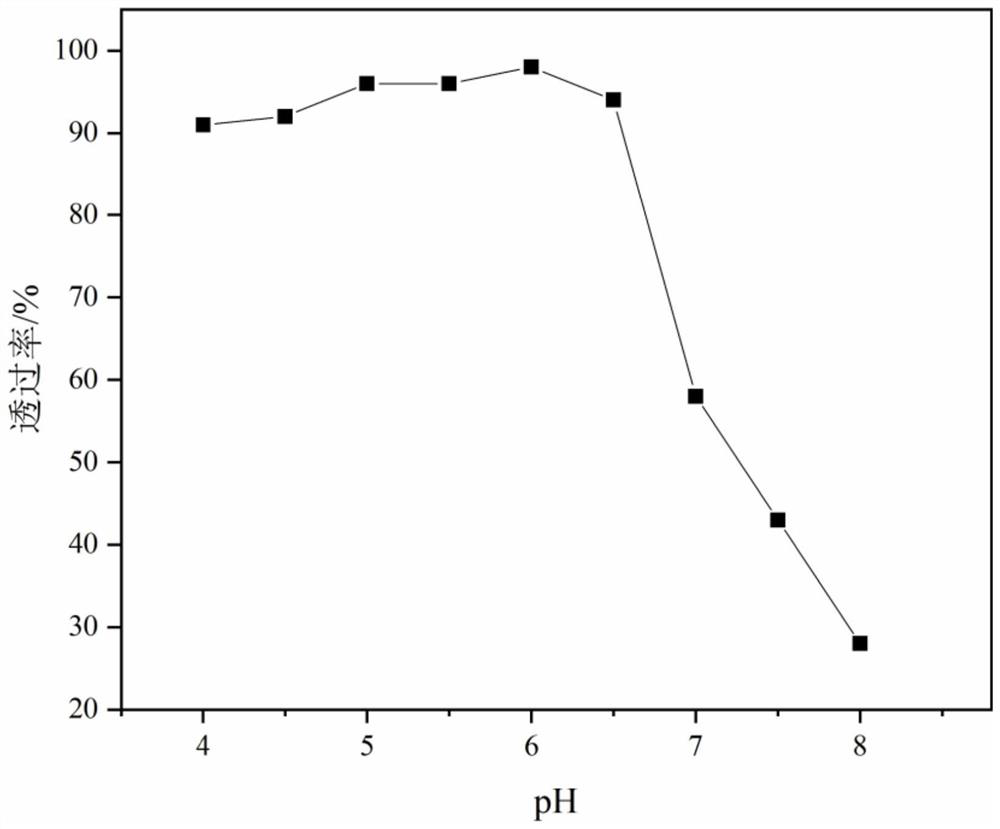

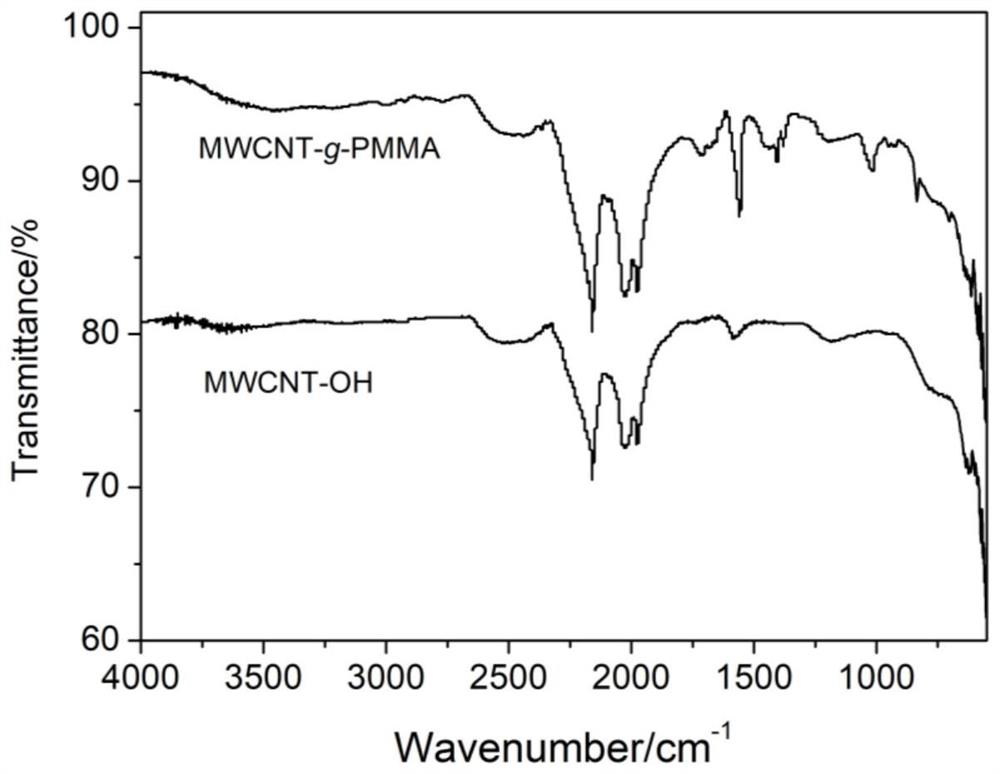

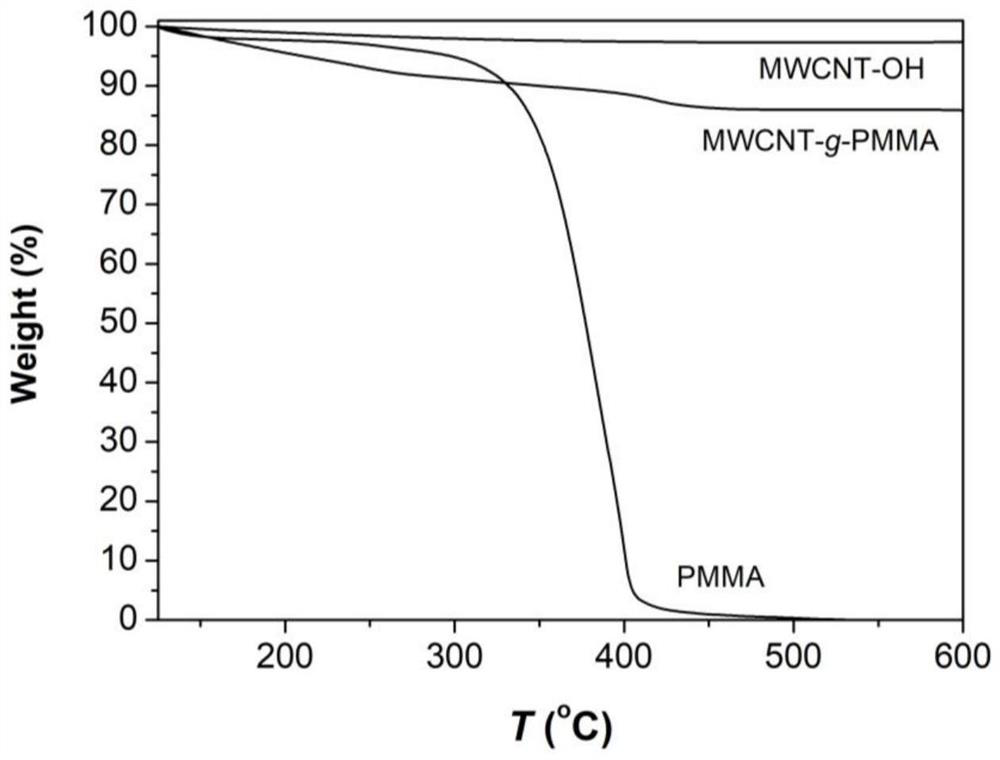

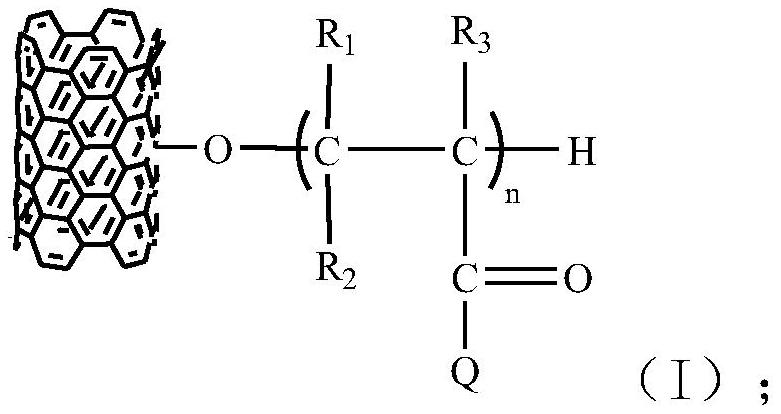

Polymer-modified carbon nanotube and preparation method thereof

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +1

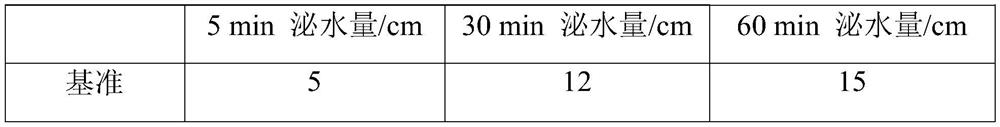

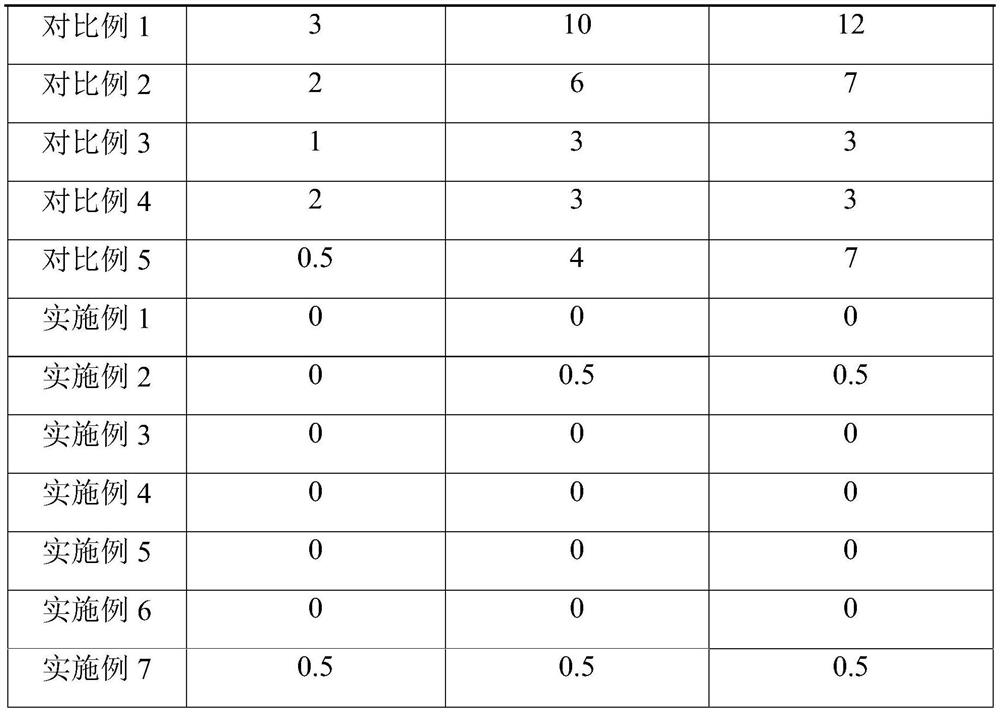

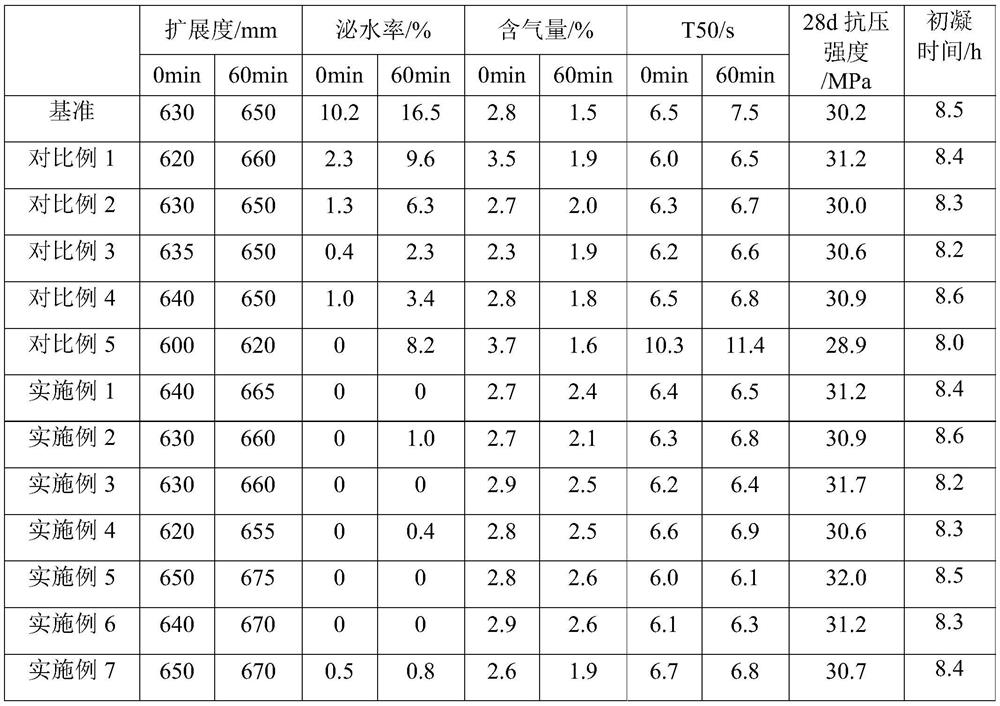

Bio-based concrete workability regulator and preparation method thereof

Owner:CHINA WEST CONSTR ACAD OF BUILDING MATERIALS CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap

![Synthesis method of 2-chloro-1-(2, 2-dimethyl-4H-benzo [1, 3] dioxin-6-yl) ethanone Synthesis method of 2-chloro-1-(2, 2-dimethyl-4H-benzo [1, 3] dioxin-6-yl) ethanone](https://images-eureka.patsnap.com/patent_img_release/960fd456-d114-4c0f-98c4-62339868eec0/HDA0003274737570000011.png)