Bio-based concrete workability regulator and preparation method thereof

A concrete and conditioner technology, applied in the field of concrete admixtures, can solve the problems of reducing the working performance and pumping performance of concrete, affecting the mechanical properties of hardened concrete, and the lack of compatibility of polycarboxylate superplasticizers, etc., to improve the wrapping property , avoid excessive gas content, improve the effect of coating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

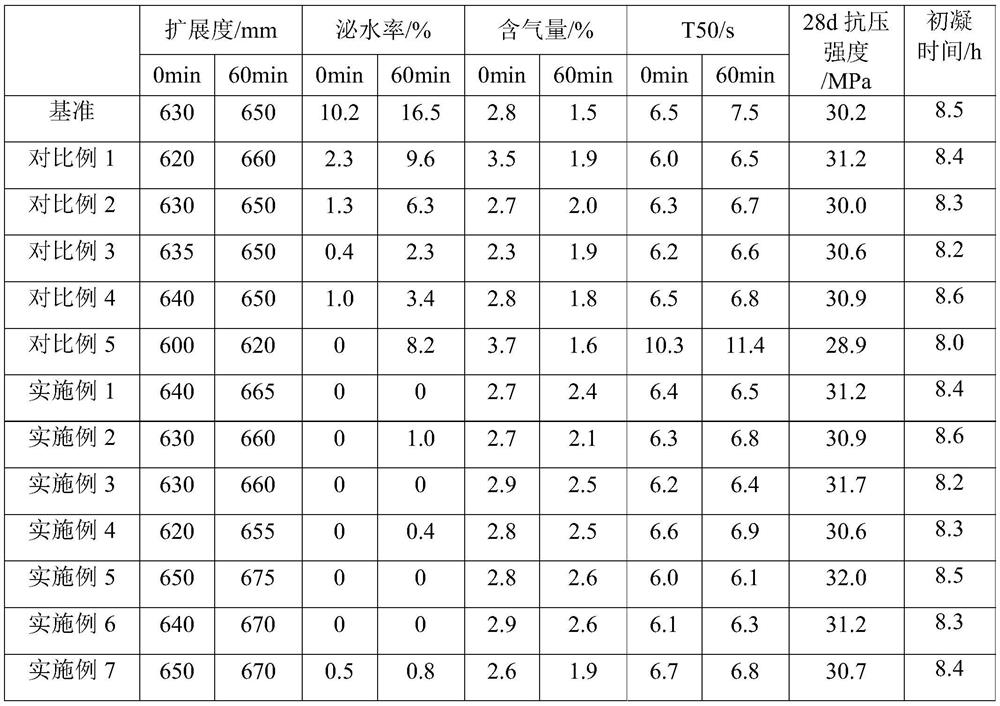

Embodiment 1

[0035] A preparation method of bio-based concrete and workability regulator, the specific steps are as follows:

[0036] (1) Weigh 90g glycerol, 56g alkali lignin (weight average molecular weight 30,000), 28g maltose and 3g water-soluble polyvinyl alcohol (weight average molecular weight is 80,000, degree of alcoholysis is 75%) in the reaction vessel , the temperature was raised to 60° C., and the stirring was continued to dissolve to obtain a biomass polyhydroxy melt.

[0037] (2) Continuously add 2g of Nadic anhydride to the biomass polyhydroxy melt in step (1) within 0.5 hour, control the reaction temperature at 80°C, and react for 3 hours to obtain the biomass polyhydroxy unsaturated condensate .

[0038] (3) Add 1 g of triisocyanate dropwise to the biomass polyhydroxy unsaturated condensate in step (2), dropwise for 0.5 hour, control the reaction temperature to 70° C., and react for 3 hours to obtain a biomass polyhydroxy cross-linked body.

[0039] (4) Add deionized water t

Embodiment 2

[0043] A preparation method of bio-based concrete and workability regulator, the specific steps are as follows:

[0044] (1) Take by weighing 45g glycerol, 59g sodium alkali lignin carboxylate (weight average molecular weight 10,000), 22.5g lactose and 3g water-soluble polyvinyl alcohol (weight average molecular weight is 60,000, alcoholysis degree is 88%) In the reaction vessel, the temperature was raised to 50° C., and stirring was continued to dissolve to obtain a biomass polyhydric melt.

[0045] (2) Continuously add 4.5g itaconic anhydride to the biomass polyhydroxy melt in step (1) within 1 hour, control the reaction temperature at 90° C., and react for 2 hours to obtain biomass polyhydroxy unsaturated condensation fit.

[0046] (3) Add 0.8 g of lysine diisocyanate dropwise to the unsaturated condensate of biomass polyhydroxyl in step (2), dropwise for 0.5 hour, control the reaction temperature at 80° C., and react for 4 hours to obtain biomass polyhydroxyl cross-linked b

Embodiment 3

[0051] A preparation method of bio-based concrete and workability regulator, the specific steps are as follows:

[0052] (1) Take by weighing 90g glycerol, 36g potassium alkali lignin carboxylate (weight-average molecular weight 15,000), 27g galactose and 3.6g water-soluble polyvinyl alcohol (weight-average molecular weight is 25,000, alcoholysis degree is 88% ) in a reaction vessel, the temperature is raised to 50° C., and stirring is continued to dissolve to obtain a biomass polyhydroxy melt.

[0053] (2) Continuously add 6.3g maleic anhydride to the biomass polyhydroxy melt in step (1) within 1 hour, control the reaction temperature at 70°C, and react for 3 hours to obtain biomass polyhydroxy unsaturated condensation fit.

[0054] (3) Add 1.8 g of hexamethylene diisocyanate dropwise to the biomass polyhydroxyl unsaturated condensate in step (2), dropwise for 0.5 hour, control the reaction temperature at 80° C., and react for 5 hours to obtain biomass poly Hydroxyl crosslinke

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap