Polymer-modified carbon nanotube and preparation method thereof

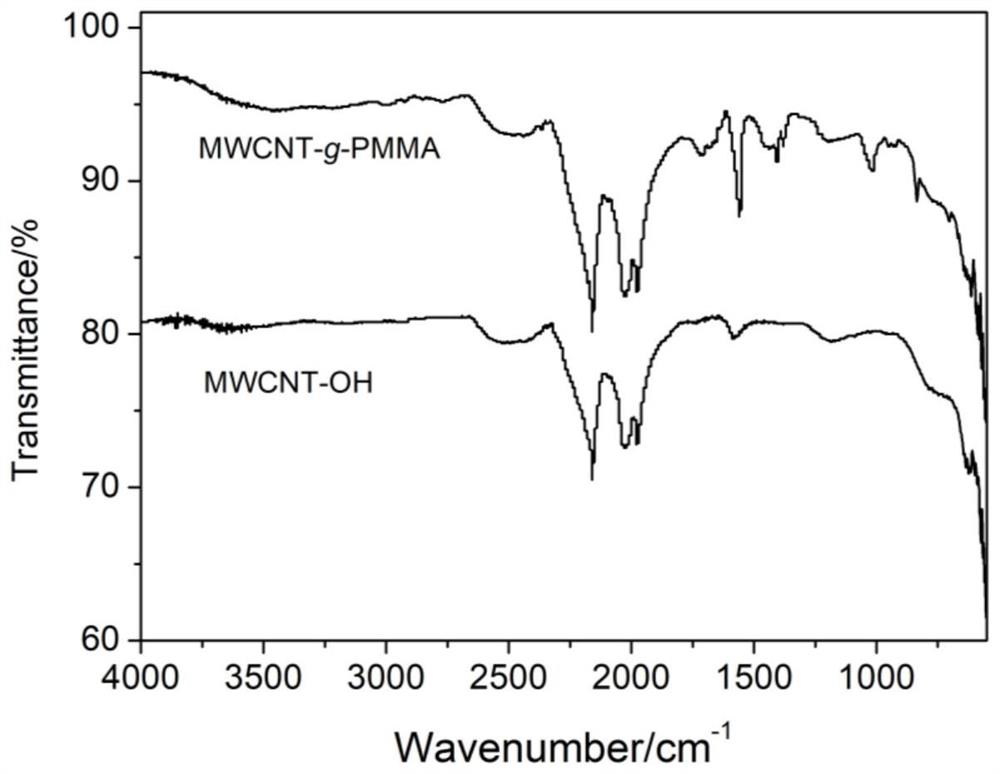

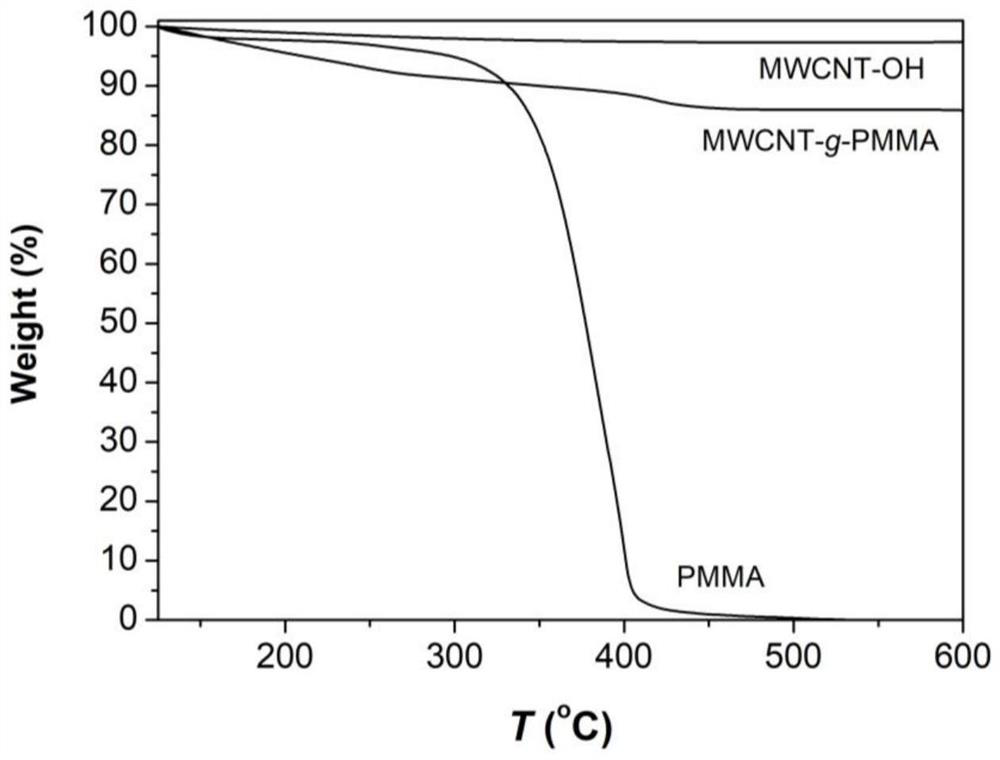

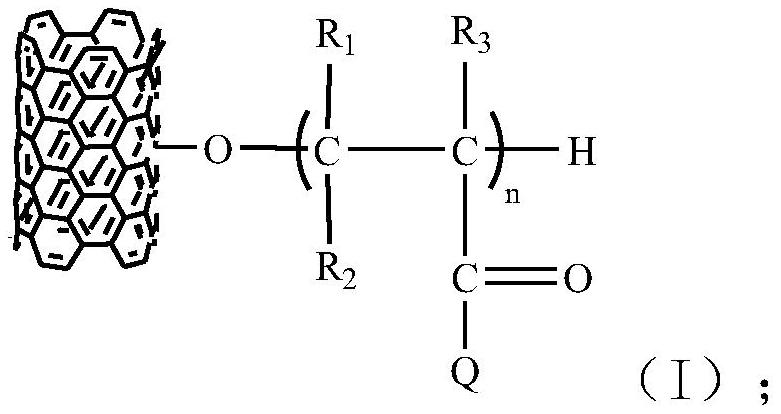

A carbon nanotube and polymer technology, applied in the fields of carbon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of thiol residue, complex reaction, long time consumption, etc., and achieve mild reaction, simple preparation, and short time consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Vacuumize a 100 ml Schlenk reaction bottle with a branched mouth equipped with magnets, bake the bottle with an electric heat gun for 3 minutes under vacuum, cool to room temperature (about 25°C), replace it with nitrogen three times, and finally fill the bottle with 0.1MPa nitrogen. The reaction was placed in a constant temperature magnetic water bath with a set reaction temperature (20°C). Add about 0.18 g of potassium hydride stored in mineral oil into the bottle, wash off the mineral oil with dry tetrahydrofuran 5 mL / time for a total of three times, then drain the solvent, and accurately weigh the mass of potassium hydride to obtain 1.47 mmol (0.0590 g) of dried potassium hydride. 10 mL of tetrahydrofuran and 0.35 g of hydroxylated carbon nanotube powder (5.58% by weight of hydroxyl group) were sequentially added into the bottle, and the reaction was initiated overnight. Add 1 mL of methyl methacrylate to the bottle, and after overnight polymerization, pour anhydro

Embodiment 2

[0055] Vacuumize a 100 ml Schlenk reaction bottle with a branched mouth equipped with magnets, bake the bottle with an electric heat gun for 3 minutes under vacuum, cool to room temperature (about 25°C), replace it with nitrogen three times, and finally fill the bottle with 0.1MPa nitrogen. The reaction was placed in a constant temperature magnetic water bath with a set reaction temperature (55°C). Add 1.25 mmol of dimethyl sulfoxide-potassium complex to the bottle. Add 10 mL of tetrahydrofuran / methyl perfluorobutyl ether mixed solution (volume ratio 1:9), and 0.33 g of hydroxylated carbon nanotube powder (hydroxyl content 6.05 wt%) into the bottle in sequence, and initiate the reaction overnight. Add 2 mL of 3,3,4,4,5,5,6,6,7,7,8,8,9,9,10,10,10-heptadecafluorodecyl acrylate to the bottle, polymerize for 1 hour , Pour anhydrous methanol into the reaction bottle to quench the polymerization. After quenching, the material in the bottle was collected by filtration, washed with

Embodiment 3

[0058] Vacuumize a 100 ml Schlenk reaction bottle with a branched mouth equipped with magnets, bake the bottle with an electric heat gun for 3 minutes under vacuum, cool to room temperature (about 25°C), replace it with nitrogen three times, and finally fill the bottle with 0.1MPa nitrogen. The reaction was placed in a constant temperature magnetic water bath with a set reaction temperature (55°C). Add 1.23mmolmmol of dimethyl sulfoxide-sodium complex to the bottle. 10 mL of dimethyl sulfoxide and 0.56 g of hydroxylated carbon nanotube powder (3.25 wt %) of hydroxylated carbon nanotube powder were sequentially added into the bottle, and the reaction was initiated overnight. Add 5 mL of dimethylaminoethyl methacrylate to the bottle, polymerize for 1 hour, and pour anhydrous methanol into the reaction bottle to quench the polymerization. After quenching, the material in the bottle was collected by filtration, washed with dichloromethane, dried in vacuum at 50° C. to constant weig

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap