Reactive compound

a technology of reactive compounds and compounds, applied in the field of reactive compounds, can solve the problems of difficult precise control of polymerization and hard to improve the purity of compounds, and achieve the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

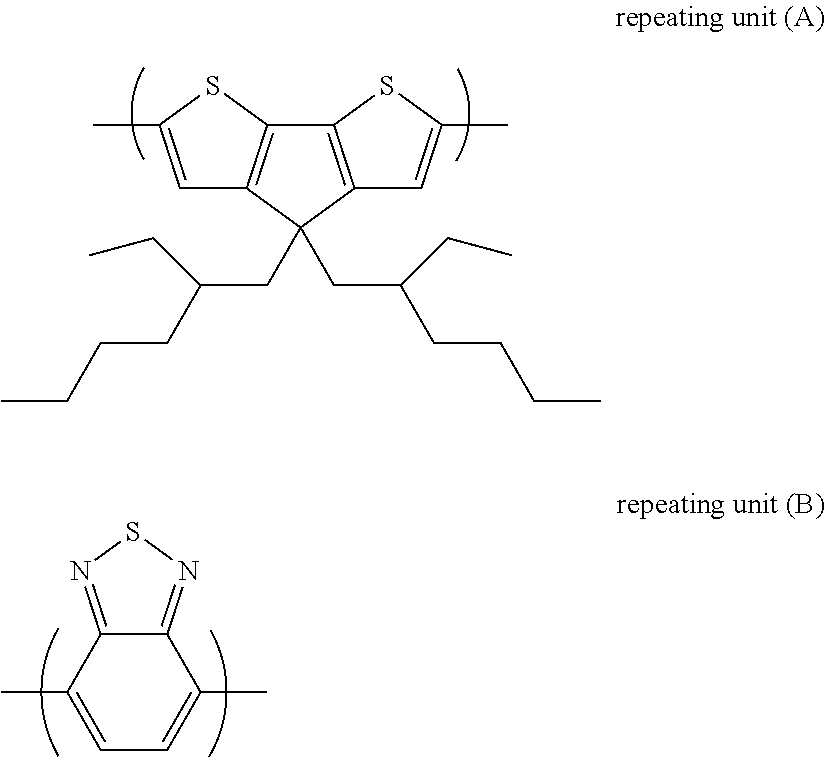

Image

Examples

example 1

Synthesis of Compound 3

[0155]

[0156]Into a four-necked flask were added 9.50 g (20.00 mmol) of a compound 1 synthesized by a method described in International Publication (WO2011 / 052709A1) and 100 mL of diethyl ether, and an argon gas was introduced into and bubbled through the resultant reaction liquid at room temperature (25° C.) for 30 minutes. The reaction liquid was cooled down to −70° C., then, 29.3 mL of a -butyllithium solution (1.64 mol / L, hexane solution) was added, and the mixture was stirred at room temperature for 2 hours. The reaction liquid was cooled down to −70° C., then, 5.20 g (50.00 mmol) of trimethoxyborane was added, and the mixture was stirred for 2 hours at −70° C. with no variation of temperature. Disappearance of a peak of the compound 1 and generation of a compound 2 were confirmed by liquid chromatography, and the reaction was terminated.

[0157]Into the reaction liquid was charged a 10 w % acetic acid aqueous solution (100 mL), and a liquid separating oper

example 2

Synthesis of Compound 6

[0160]

[0161]Into a four-necked flask were added 10.62 g (20.00 mmol) of a compound 4 synthesized by a method described in International Publication (WO2011 / 052709A1) and 100 mL of diethyl ether, and an argon gas was introduced into and bubbled through the resultant reaction liquid at room temperature (25° C.) for 30 minutes. The reaction liquid was cooled down to −70° C., then, 29.3 mL of a -butyllithium solution (1.64 mol / L, hexane solution) was added, and the mixture was stirred at room temperature for 2 hours. The reaction liquid was cooled down to −70° C., then, 5.20 g (50.00 mmol) of trimethoxyborane was added, and the mixture was stirred for 2 hours at −70° C. with no variation of temperature. Disappearance of a peak of the compound 4 and generation of a compound 5 were confirmed by liquid chromatography, and the reaction was terminated.

[0162]Into the reaction liquid was charged a 10 w % acetic acid aqueous solution (100 mL), and a liquid separating ope

example 3

Synthesis of Compound 9

[0165]

[0166]Into a four-necked flask were added 2.91 g (4.00 mmol) of a compound 7 synthesized by a method described in International Publication (WO2011 / 052709A1) and 20 mL of diethyl ether, an argon gas was introduced into and bubbled through the resultant reaction liquid at room temperature (25° C.) for 30 minutes. The reaction liquid was cooled down to −70° C., then, 5.9 mL of a -butyllithium solution (1.64 mol / L, hexane solution) was added, and the mixture was stirred at room temperature for 2 hours. The reaction liquid was cooled down to −70° C., then, 1.04 g (10.00 mmol) of trimethoxyborane was added, and the mixture was stirred for 2 hours at −70° C. with not variation of temperature. Disappearance of a peak of the compound 7 and generation of a compound 8 were confirmed by liquid chromatography, and the reaction was terminated.

[0167]Into the reaction liquid was charged a 10 w % acetic acid aqueous solution (20 mL), and a liquid separating operation w

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap