Proton exchange membrane and preparation method thereof

A technology of proton exchange membrane and proton exchange, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrochemical generator, etc., can solve the problems of large energy consumption, achieve the effect of reducing preparation cost and solving large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a preparation method of the proton exchange membrane, and the preparation method of the proton exchange membrane comprises the steps:

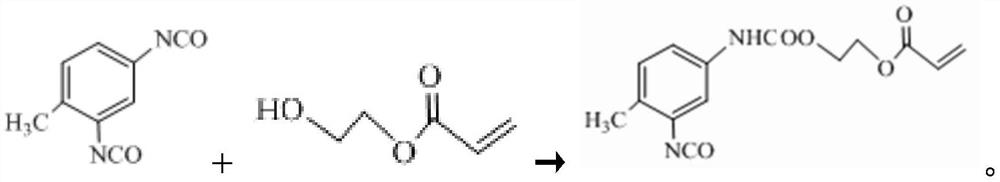

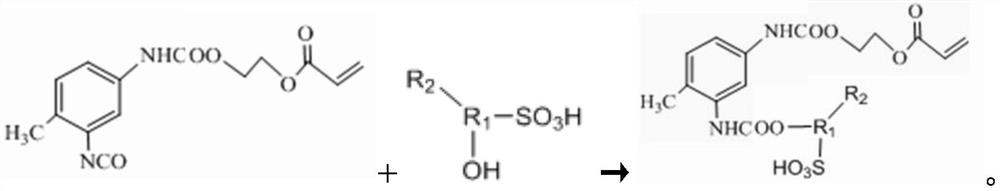

[0050] S100, adding an unsaturated ester to the isocyanate, adjusting the reaction temperature, so that the isocyanate group with high reactivity in the isocyanate reacts with the unsaturated ester, and the reaction is completed to obtain an intermediate product.

[0051] The present invention selects a hydroxyl-containing unsaturated ester, and the hydroxyl group in the unsaturated ester reacts with an isocyanate group in the isocyanate. Specifically, when the isocyanate is selected as 2,4-toluene isocyanate and the unsaturated ester is selected as hydroxyethyl acrylate The reaction equation is as follows:

[0052]

[0053]in, is 2,4-toluene isocyanate; is hydroxyethyl acrylate; as an intermediate product.

[0054] Further, a first catalyst may be added in step 100 to speed up the reaction rat

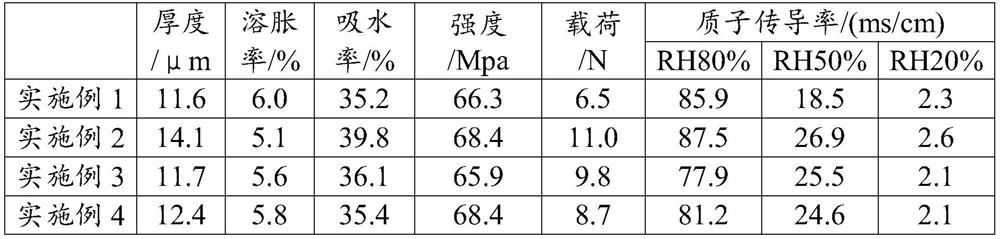

Embodiment 1

[0083] N,N-dimethylformamide is added to the strongly acidic cationic proton exchange resin containing sulfonic acid groups to dilute to a proton exchange resin solution with a solid content of 60-80%.

[0084] Under normal temperature, hydroxyethyl acrylate is slowly added to 2,4-toluene isocyanate within 15 minutes, the temperature is raised to 60°C, and the reaction is kept for 60-120 minutes to obtain an intermediate product.

[0085] After adding the intermediate product and 0.1% stannous octoate to the proton exchange resin solution, after mixing and stirring for half an hour, the temperature was raised to 75 ° C, and the reaction was kept for 2 hours to obtain an oligomer resin with a solid content of 50-60%. between.

[0086] The synthetic oligomer resin was added with 0.05% photoinitiator 1173 (2-hydroxy-2-methyl-1-phenyl-1-propanone), and the film was formed on the coater under light conditions (UV curing of LED lamp). The wavelength is between 350-400nm, and the dista

Embodiment 2

[0089] N,N-dimethylformamide is added to the strongly acidic cationic proton exchange resin containing sulfonic acid group to dilute it into a proton exchange resin solution with a solid content of 60-80%.

[0090] The phosphoric acid added in PEG200 was adjusted to pH 5 to 6. At room temperature, PEG200 with pH 5 to 6 was slowly added to 2,4-toluene isocyanate within 15 minutes, and the temperature was raised to 60°C for 30 to 70 minutes. of double-blocked isocyanates.

[0091] Slowly add hydroxyethyl acrylate and 0.01% hydroquinone polymerization inhibitor to the modified double-terminated isocyanate, heat up to 60°C, and keep the temperature for 30 minutes, then add dilauric acid, heat up to 75°C, and continue to keep the temperature 2h, the intermediate product was obtained by the reaction.

[0092] Add the intermediate product and 0.01% stannous octoate to the proton exchange resin solution, and after mixing and stirring for half an hour, the temperature is raised to 75 ° C

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proton conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap