Continuous gas reaction device, and continuous dissolved gas reaction device

A technology of gas reaction and dissolved gas, applied in the chemical method of reacting liquid and gas medium, chemical/physical/physicochemical fixed reactor, transportation and packaging, etc., can solve the inefficiency of recycling process and equipment Reduced operating rate, increased maintenance costs, etc., achieved the effect of small and simple structure, reduced gas consumption, and reduced equipment scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Next, modes for implementing the present invention will be described in detail with reference to the drawings. In the following description, the case where incineration ash is slurried and processed using cement kiln exhaust gas (henceforth "exhaust gas") is demonstrated as an example.

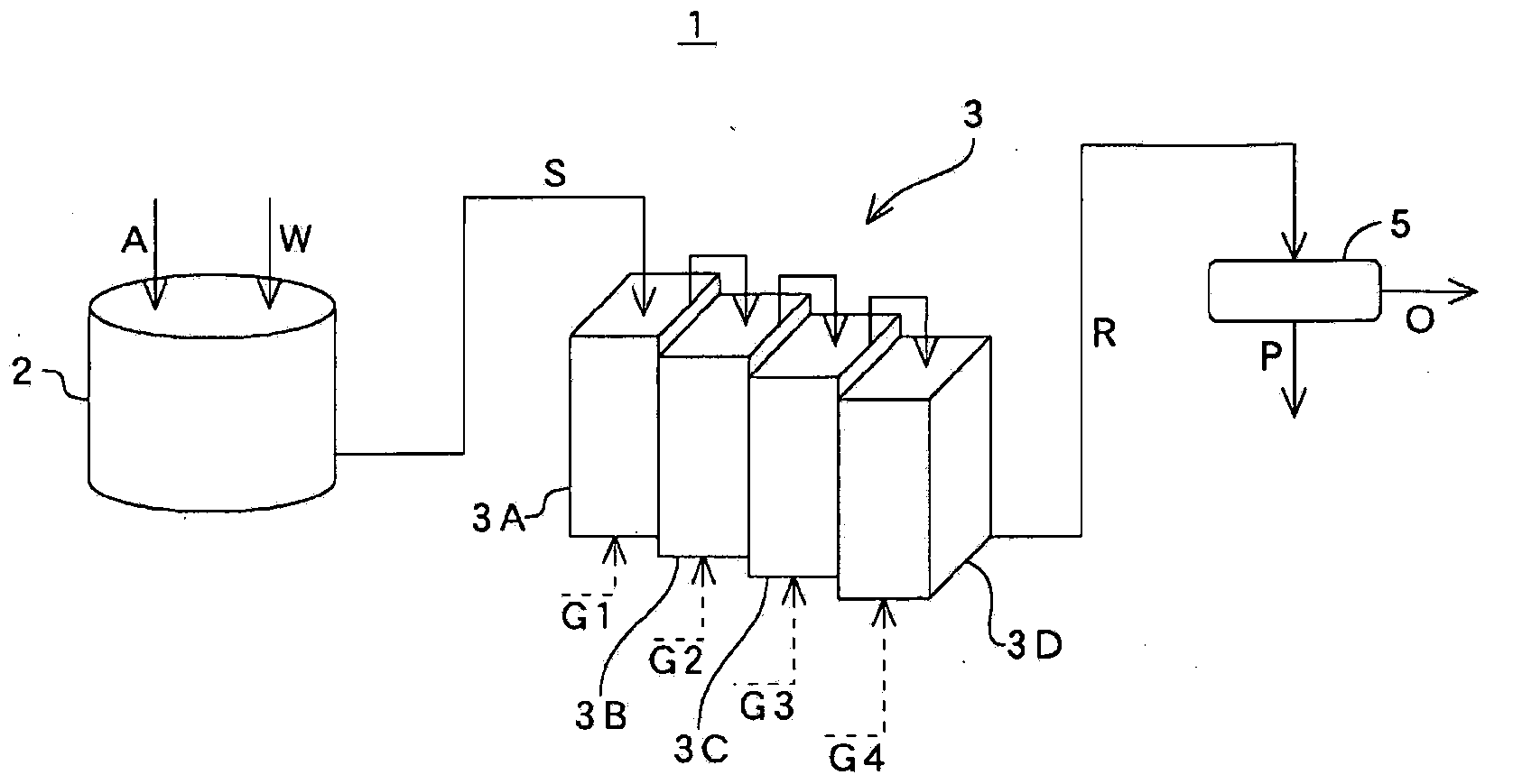

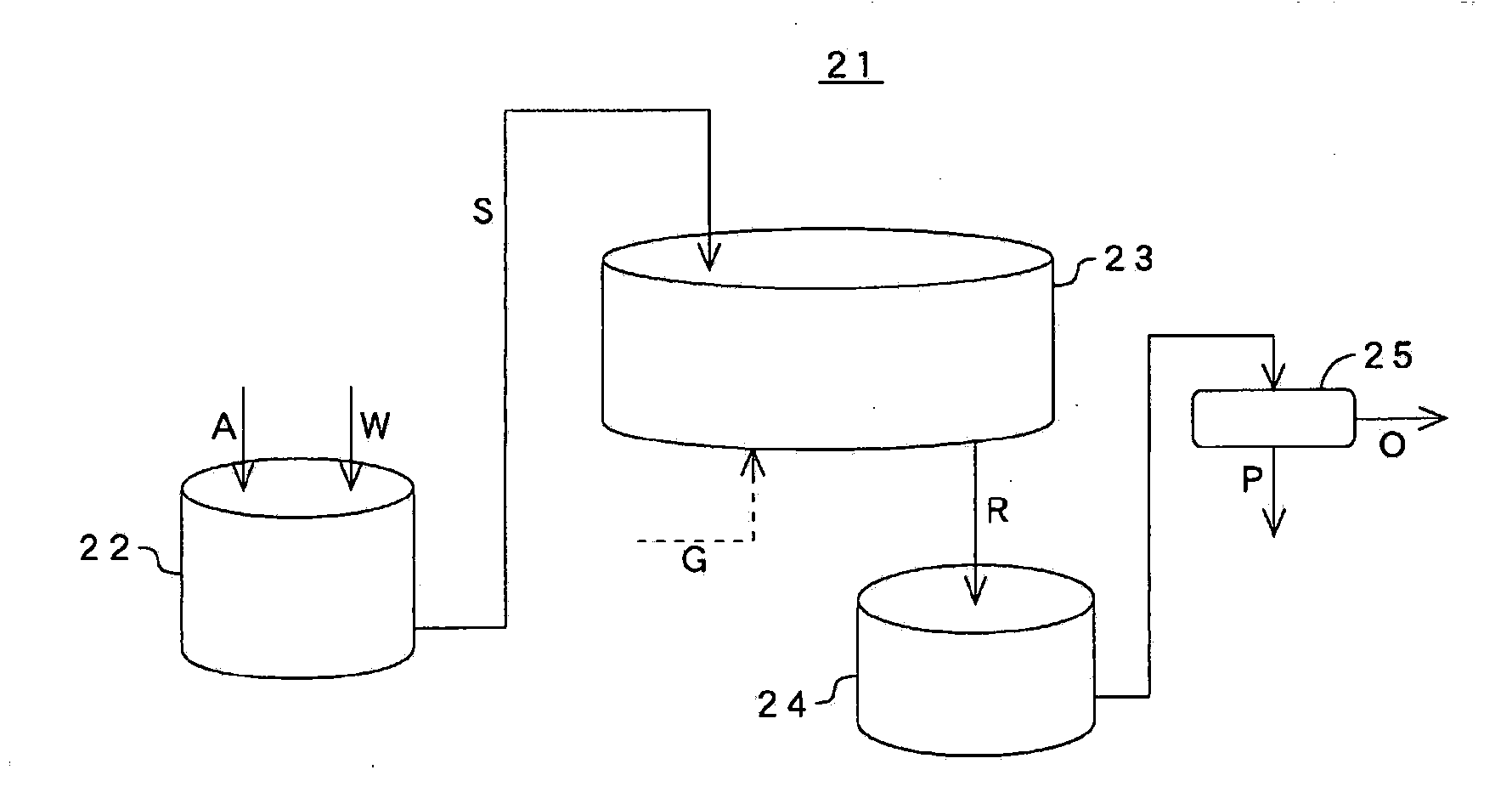

[0031] figure 1 An embodiment of the continuous dissolved gas reactor of the present invention is shown, and the continuous dissolved gas reactor 1 is composed of a dissolution tank 2, a continuous gas reactor 3, a filter 5, and the like.

[0032] The dissolving tank 2 is equipped with stirring blades and the like in the tank, and is installed to add water W to the incineration ash A to form a solid slurry S and to dissolve the salt contained in the incineration ash A in the water.

[0033] The continuous gas reaction tank 3 is composed of four stages of reaction tanks 3A to 3D arranged in series. The reaction tanks 3A to 3D of each stage are equipped with a gas diffusion plate (not show

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap