Method for converting traditional bath ratio reactive dye dyeing prescription into small bath ratio reactive dye dyeing prescription

A technology of reactive dyes and conversion methods, which is applied in the field of small bath ratio dyeing of cellulose fiber fabrics with reactive dyes, and achieves the effects of simple and fast conversion methods, increased success rate, and promotion of popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The original 1:20 traditional bath ratio reactive dye dyeing prescription:

[0027] Total Reactive Dyes 2%

[0028] The dosage of Yuanming powder is 40g / L

[0029] Soda ash dosage 16g / L

[0030] Bath ratio 1:20

[0031] In addition, if the alkali substitute agent is used instead of soda ash, the dosage is 1 / 8 of that of soda ash, and the dosage of alkali substitute agent is 2g / L

[0032] How to convert to 1:5 small bath ratio active dye dyeing prescription now?

[0033] 1. The total amount of reactive dyes is still 2%

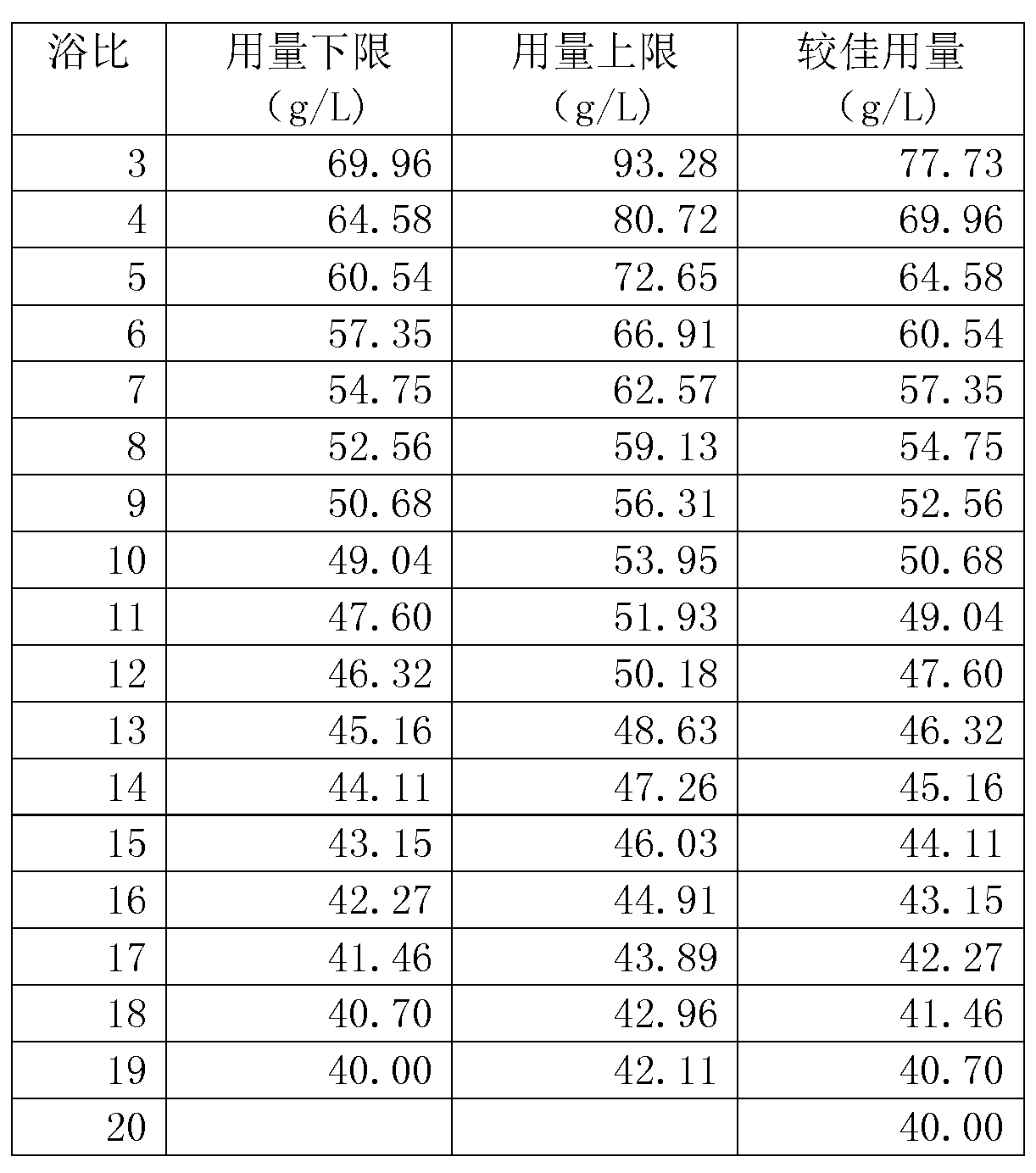

[0034] 2. Check Table 1 for the dosage of Yuanming powder and get 64.58g / L

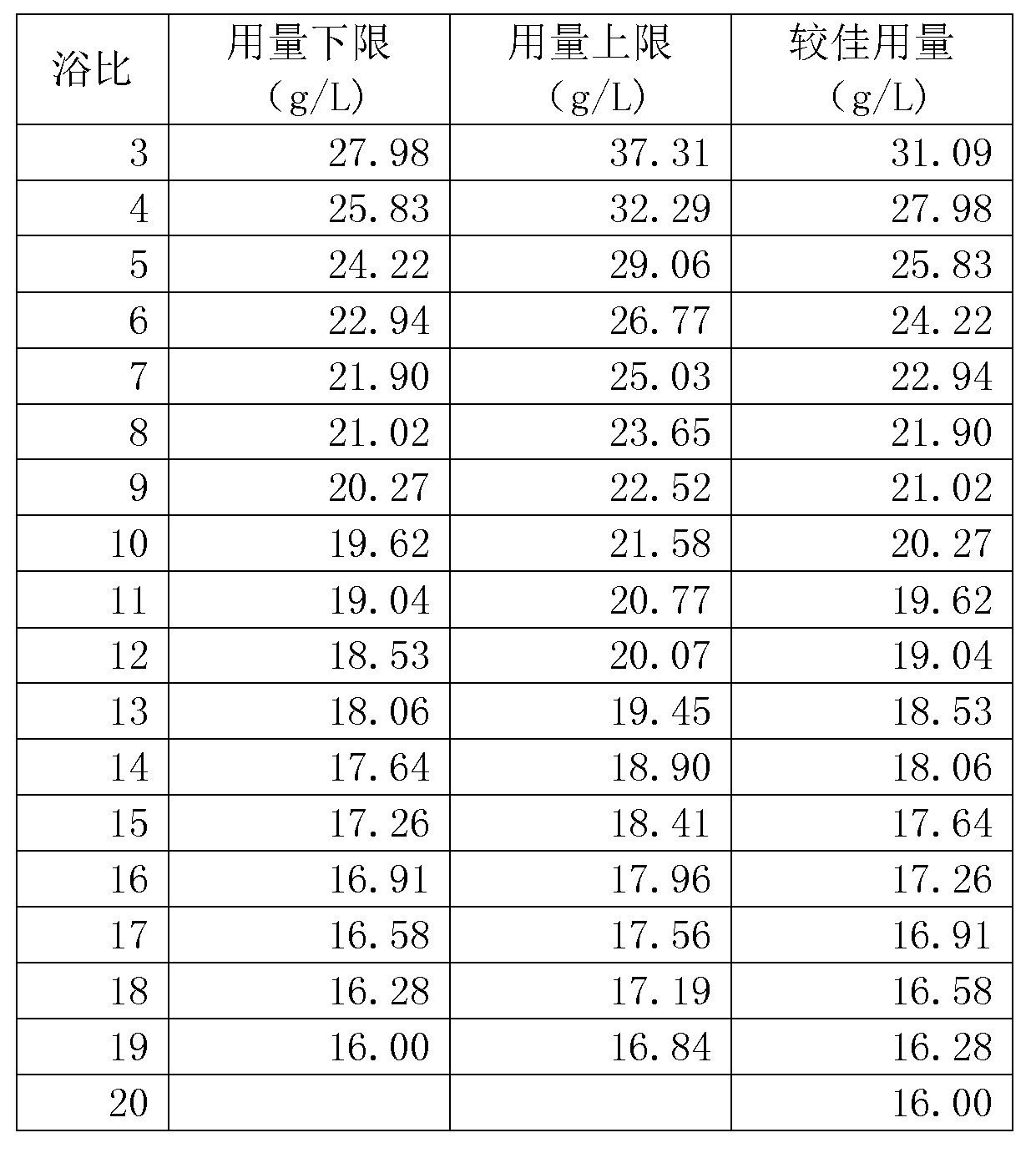

[0035] 3. Check Table 2 for the amount of soda ash to get 25.83g / L, and then divide it by 1 / 8 to get the amount of alkali substitute agent to be 3.23g / L

[0036] Now 1:5 small bath ratio reactive dye dyeing prescription:

[0037] Total Reactive Dyes 2%

[0038] The dosage of Yuanming powder 64.58g / L

[0039] Alkali agent dosage 3.23g / L

[0040] Table 1

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap