One-step forming solvent type single-component quick drying hammer finish and preparation method

A hammer-like paint, one-component technology, applied in the field of one-time forming solvent-based one-component quick-drying hammer-like paint and its preparation, can solve the problems of uneconomical, weak three-dimensional effect and high price, and achieves enhanced thixotropic activity, Reduce construction difficulty, clear pattern effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

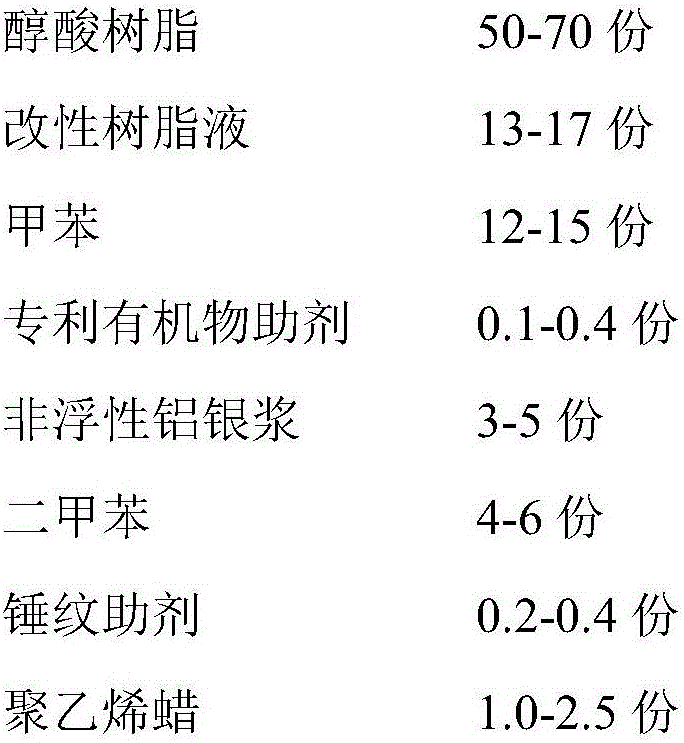

[0043] The above-mentioned one-time molding solvent-based one-component quick-drying hammer paint includes the following components by weight:

[0044]

[0045] Preparation:

[0046] (1) Add the xylene of the formula amount into the pulling cylinder, then add the non-floating aluminum silver paste of the formula amount, soak for 5min, stir evenly at 300r / min and stand by for use;

[0047] (2) drop the alkyd resin of the formula amount, the modified resin liquid of the formula amount and the toluene of two-thirds of the formula amount into the dispersion kettle successively, and disperse uniformly at 600r / min;

[0048] (3) under the slow stirring of 300r / min, the patented organic matter adjuvant of the formula amount is slowly added to the mixture obtained in step (2), after stirring 5min, the polyethylene vinegar of the formula amount is added, and the rotating speed is increased to 1000r / min, high-speed dispersion for 20min;

[0049] (4) adding the mixture obtained

Embodiment 2

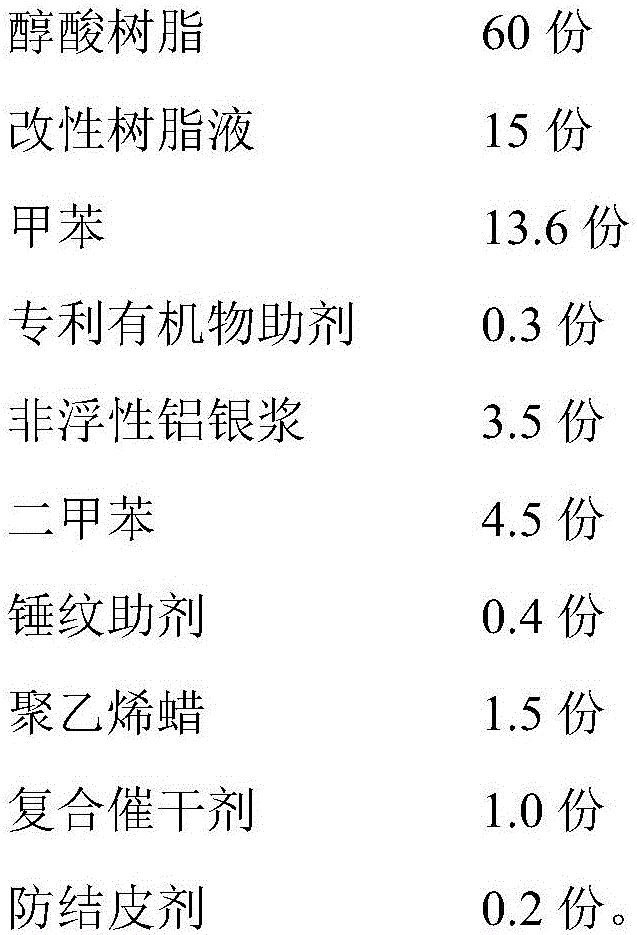

[0054] The above-mentioned one-time molding solvent-based one-component quick-drying hammer paint includes the following components by weight:

[0055]

[0056] Preparation:

[0057] (1) Add the xylene of the formula amount into the pulling cylinder, then add the non-floating aluminum silver paste of the formula amount, soak for 5min, stir evenly at 300r / min and stand by for use;

[0058] (2) drop the alkyd resin of the formula amount, the modified resin liquid of the formula amount and the toluene of two-thirds of the formula amount into the dispersion kettle successively, and disperse uniformly at 600r / min;

[0059] (3) under the slow stirring of 300r / min, the patented organic matter adjuvant of the formula amount is slowly added to the mixture obtained in step (2), after stirring 5min, the polyethylene vinegar of the formula amount is added, and the rotating speed is increased to 1000r / min, high-speed dispersion for 20min;

[0060] (4) adding the mixture obtained

Embodiment 3

[0065] The above-mentioned one-time molding solvent-based one-component quick-drying hammer paint includes the following components by weight:

[0066]

[0067] Preparation:

[0068] (1) Add the xylene of the formula amount into the pulling cylinder, then add the non-floating aluminum silver paste of the formula amount, soak for 10min, stir evenly at 400r / min and stand by for use;

[0069] (2) drop the alkyd resin of the formula amount, the modified resin liquid of the formula amount and the toluene of two-thirds of the formula amount into the dispersion kettle successively, and disperse uniformly at 800r / min;

[0070] (3) under the slow stirring of 500r / min, the patented organic matter adjuvant of the formula is slowly added to the mixture obtained in step (2), the polyethylene vinegar of the formula is added after stirring for 10min, and the rotating speed is increased to 1200r / min, high-speed dispersion for 30min;

[0071] (4) adding the mixture obtained in step (

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap