Polyamide/Polyphenylene Ether Resin Composition, and Vehicle Molded Product Prepared Therefrom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

EXAMPLES 1 TO 16 AND COMPARATIVE EXAMPLES 1 TO 5

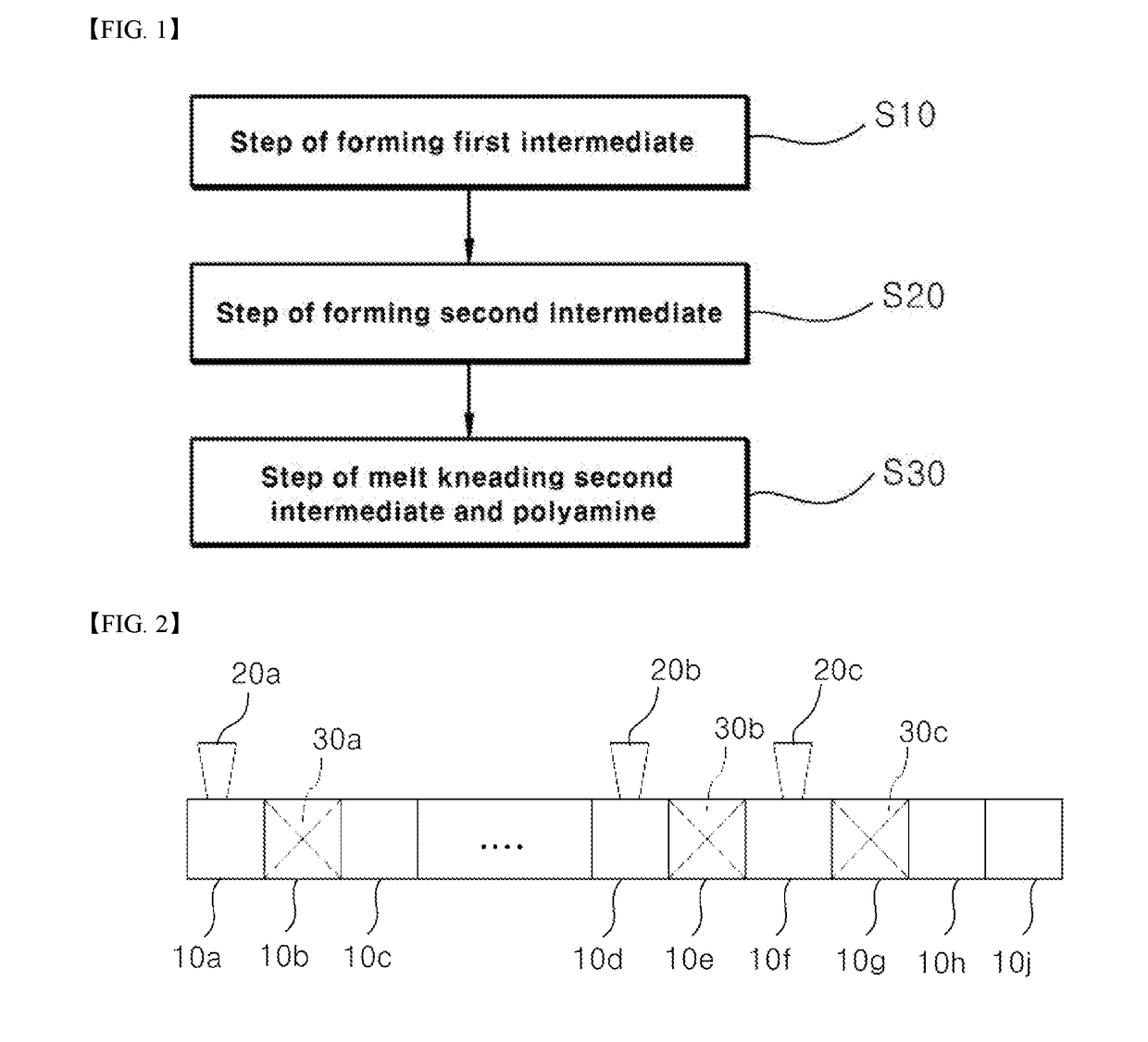

[0149]Resin compositions were prepared in pellet form by supplying components as listed in Tables 1 to 4 to a twin-screw extruder (KZW-58, Technovel Co.), followed by extrusion and kneading. The twin-screw extruder is composed of thirteen barrels, in which feeding ports are provided to the first, sixth and eighth barrels (hereinafter referred to as “Barrel 1”, “Barrel 6”, and “Barrel 8”, respectively); vacuum vents are provided to the fifth and eleventh barrels (hereinafter referred to as “Barrel 5” and “Barrel 11”, respectively); liquid feeding nozzles are provided to the sixth, eighth, and twelfth barrels (hereinafter referred to as “Barrel 6”, “Barrel 8”, and “Barrel 12”, respectively); and kneading screw elements are provided to the third, fourth, seventh, tenth, and twelfth barrels (hereinafter referred to as “Barrel 3”, “Barrel 4”, “Barrel 7”, “Barrel 10” and “Barrel 12”, respectively).

[0150]Barrels 2 to 4 were set to have a cylinde

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap