Dry Side Sensor Mounting for Sensor Chip Assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

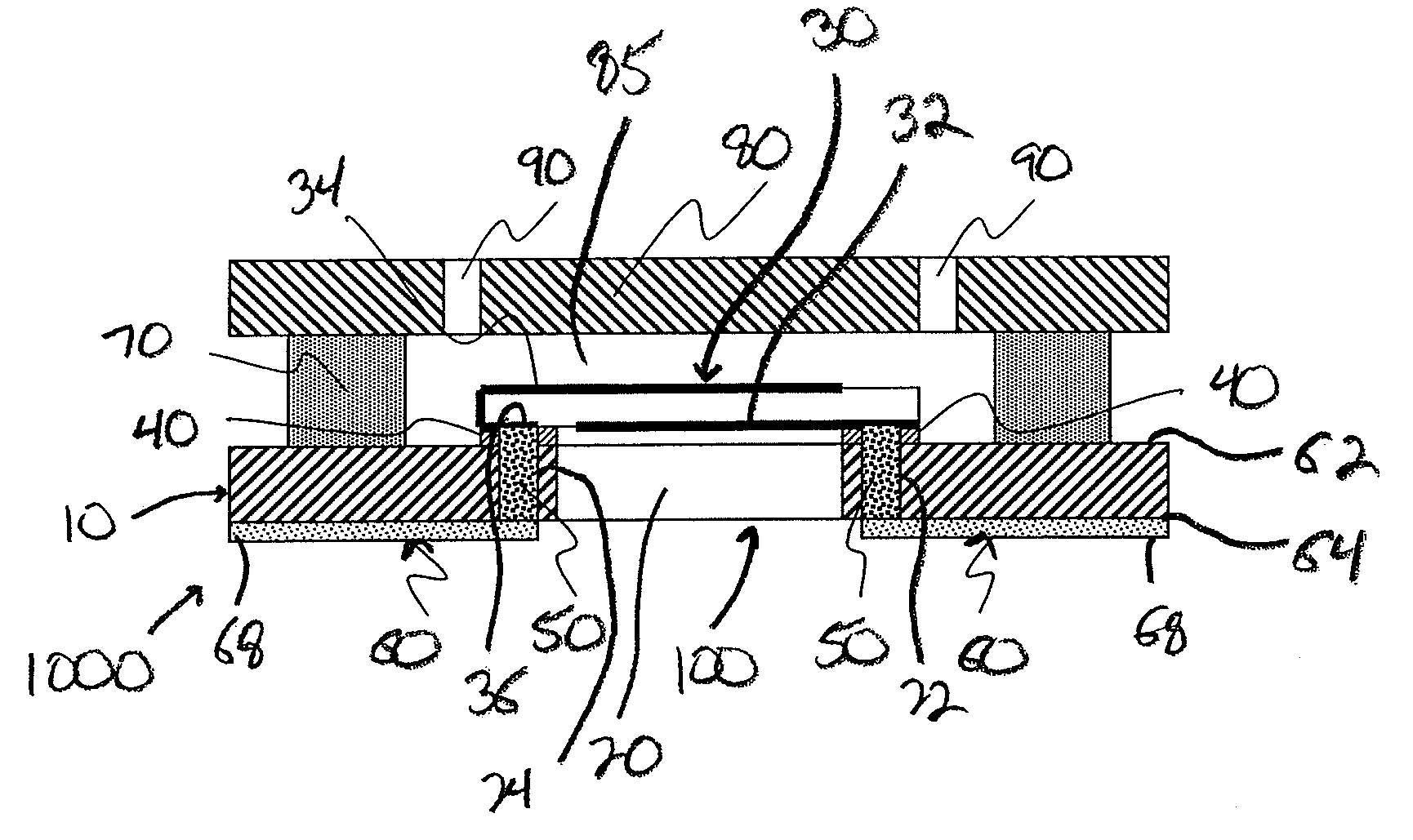

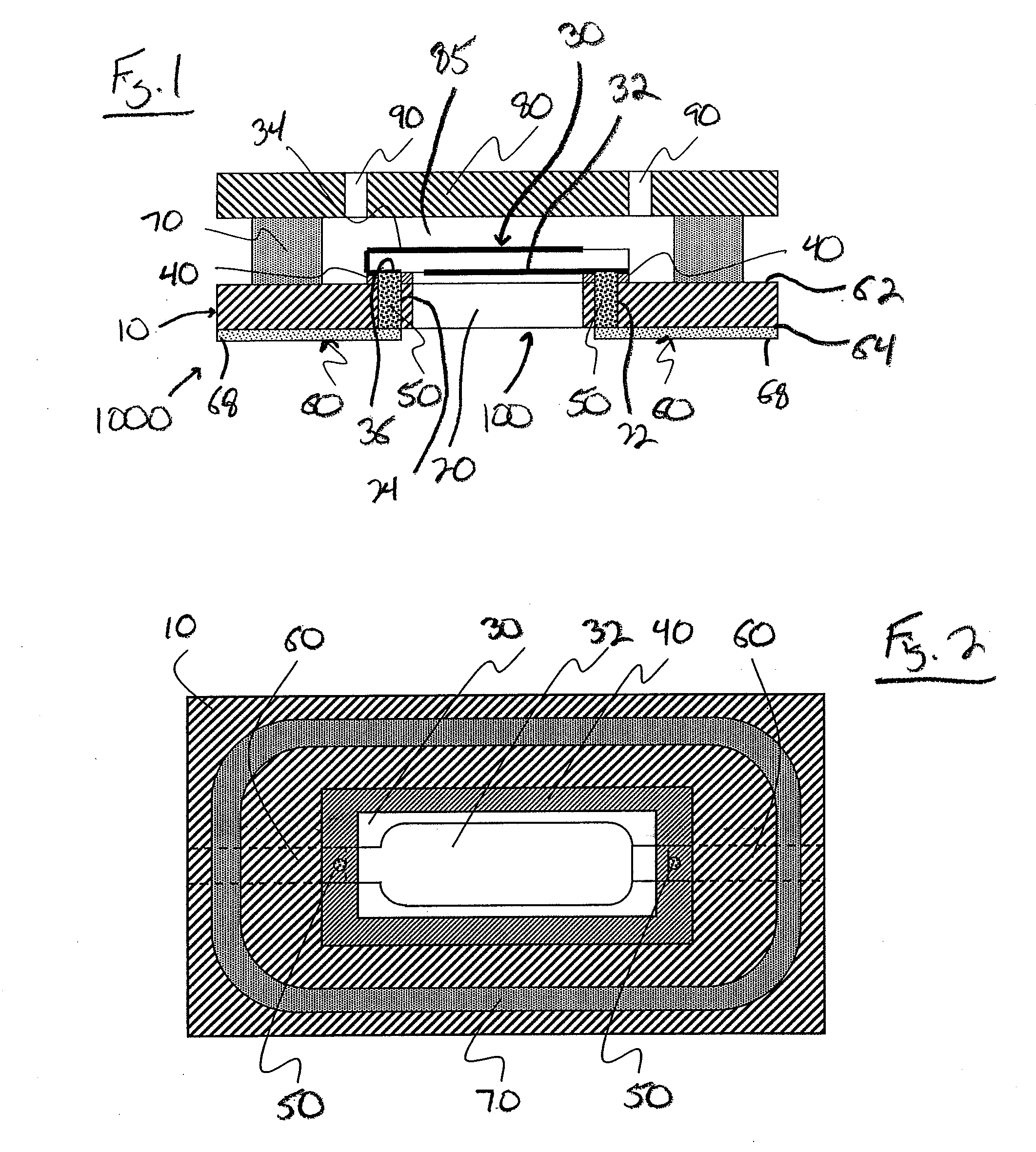

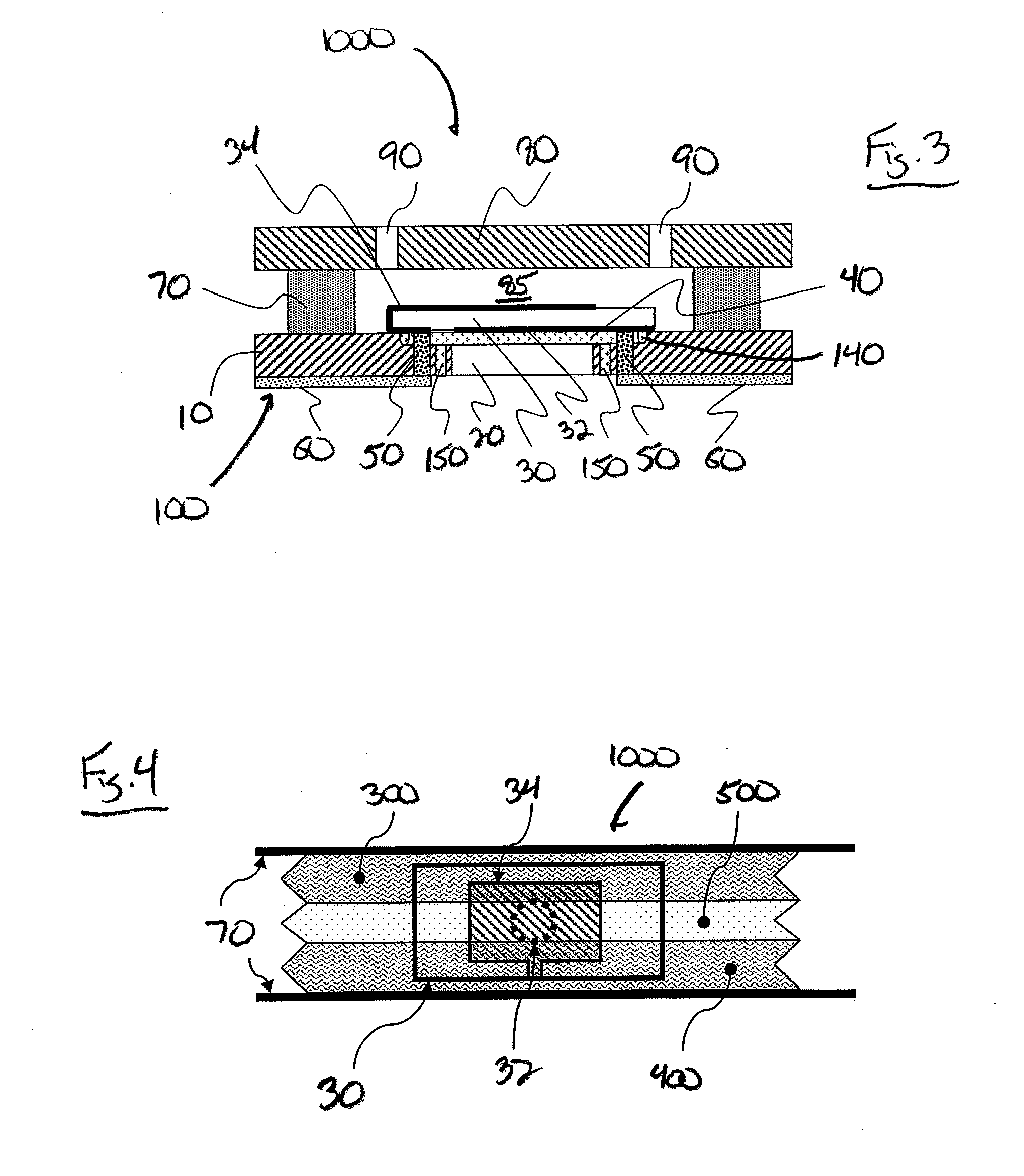

[0022]With reference now to the drawing figures in which like reference numerals represent like parts throughout the disclosure, a sensor assembly constructed according to the present invention is illustrated generally at 100 in FIG. 1. In one embodiment for the assembly shown in FIG. 1, the assembly 100 is a dry side sensor mounting assembly for a single sensing spot crystal resonator 30 assembled into a sample delivery flow cell 1000. The assembly 100 is formed with a substrate 10 of a fluid-impervious and non-conductive material that includes a central bore 20 and a pair of electrode contact bores 22, 24 disposed on opposite sides of the central bore 20, though the bores 22, 24 can be located in any suitable location around the bore 20. Additionally, the central bore 20 and the bores 22, 24 are shaped as desired to accommodate the particular structure of the assembly 100, and therefore can have any desired shape.

[0023]An oscillating crystal resonator 30 formed of a conventional quar

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flow rate | aaaaa | aaaaa |

| Electrical conductor | aaaaa | aaaaa |

| Adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap