Stack of semiconductor chips

a technology of semiconductor chips and stacks, which is applied in the direction of semiconductor devices, semiconductor/solid-state device details, electrical equipment, etc., can solve the problems of high assembly cost, high assembly cost, and inability to meet the requirements of reliability, so as to improve the adhesion between chips, increase the surface area accessible, and improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The making and using of the presently preferred embodiments are discussed in detail below. It should be appreciated, however, that the present invention provides many applicable inventive concepts that can be embodied in a wide variety of specific contexts. The specific embodiments discussed are merely illustrative of specific ways to make and use the invention, and do not limit the scope of the invention.

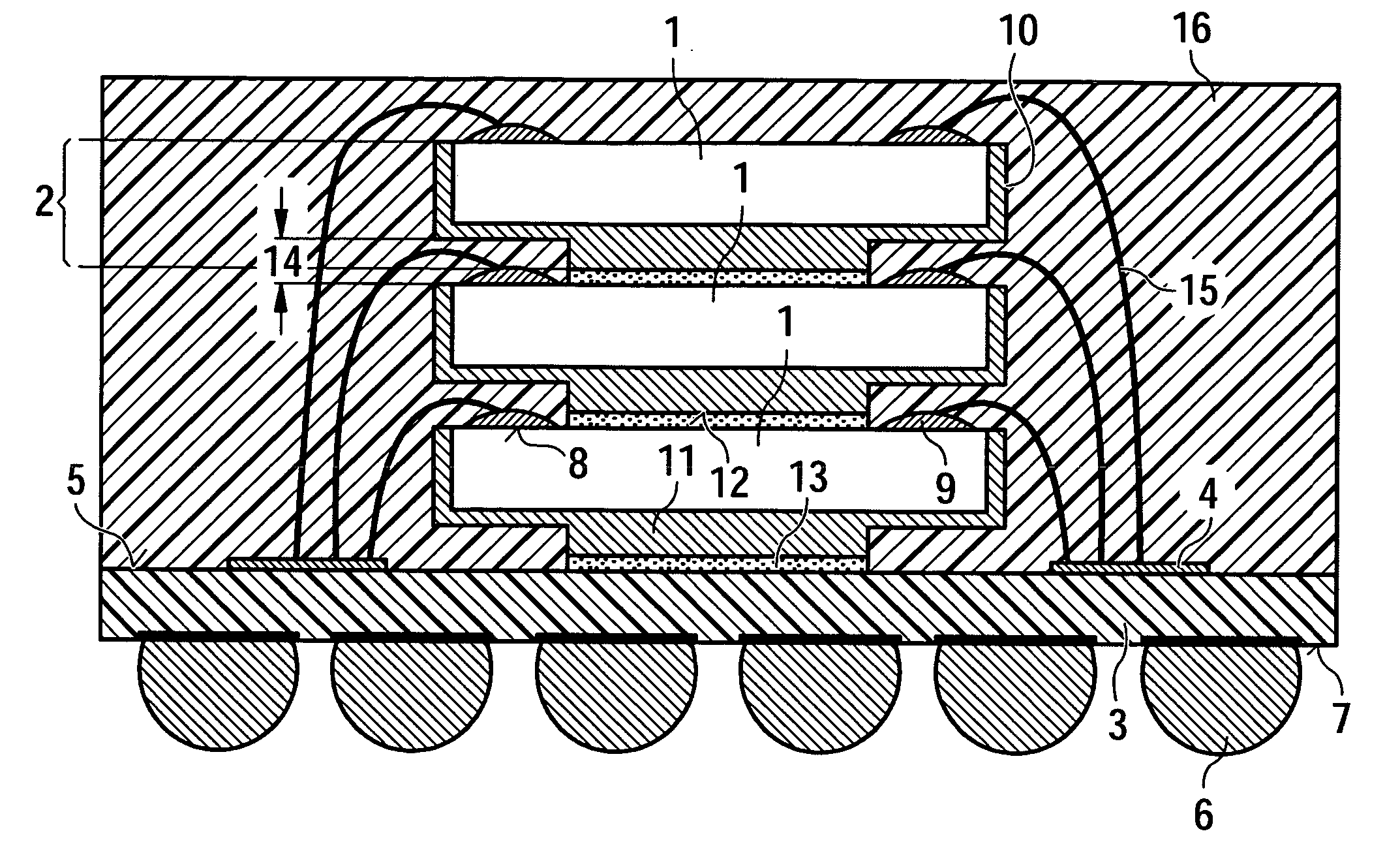

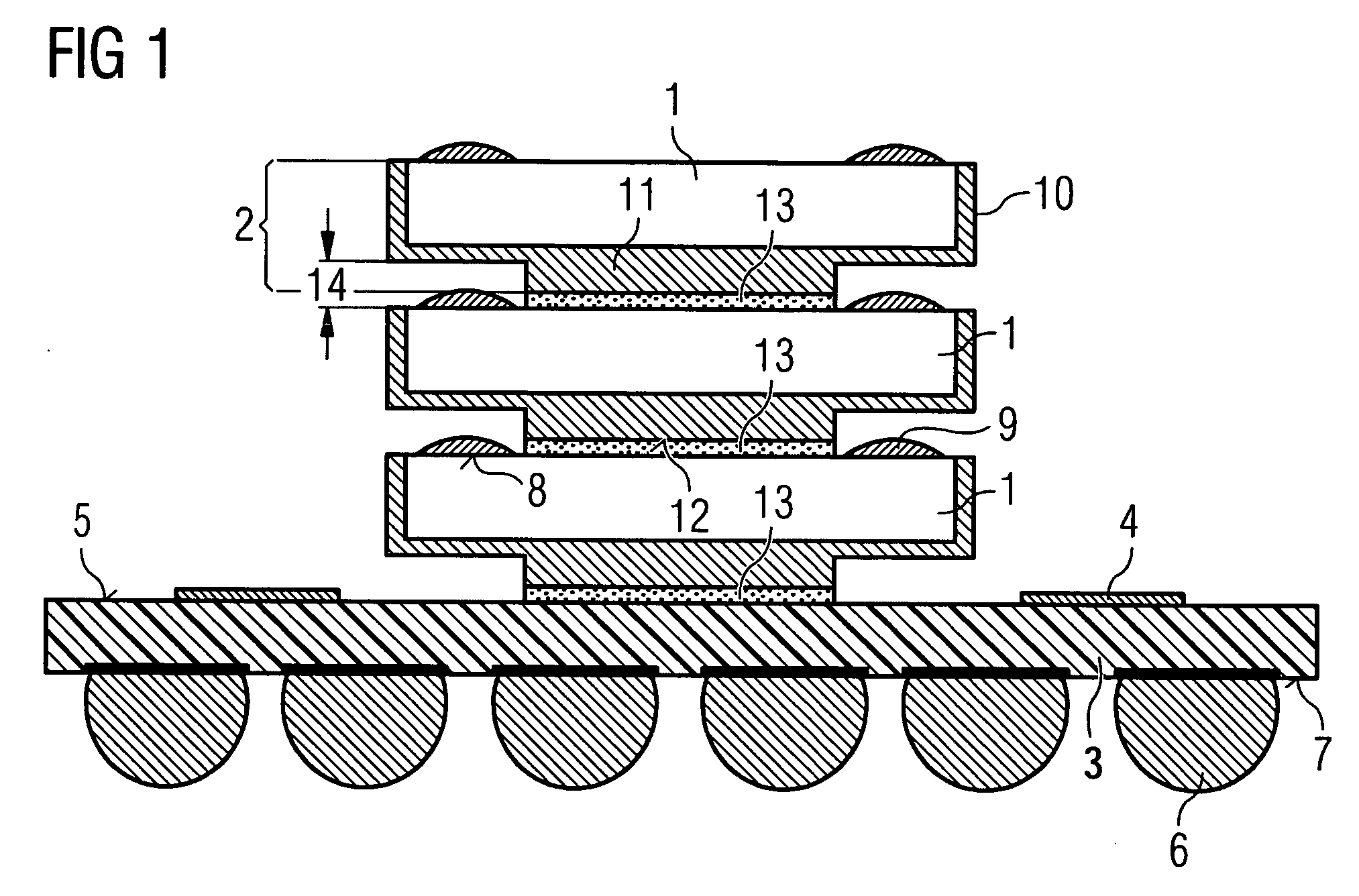

[0031]FIG. 1 shows three individual embedded semiconductor chips 1 (individual components 2) in a face-up arrangement on a carrier substrate 3. Conductor structures 4 of the upper surface 5 of the substrate 3 are electrical interconnected (not shown) with electrical contacts 6 located on the lower surface 7 of the substrate 3. In the preferred embodiments, these contacts 6 are fine pitch ball grid arrays (FBGA), by means of which the stack arrangement can be integrated into a circuit, e.g., by soldering the contacts 6 to a circuit board (not shown).

[0032] All individual chips

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap