High-temperature-resistant conductive silver adhesive used for production of LED

A technology of conductive silver glue and high temperature resistance, applied in the field of conductive glue, can solve the problems of weakened conductivity, shear strength of conductive silver glue, poor bonding strength of high temperature resistance, high cost of conductive silver glue, etc., to achieve Improve structural stability, excellent high temperature resistance, and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

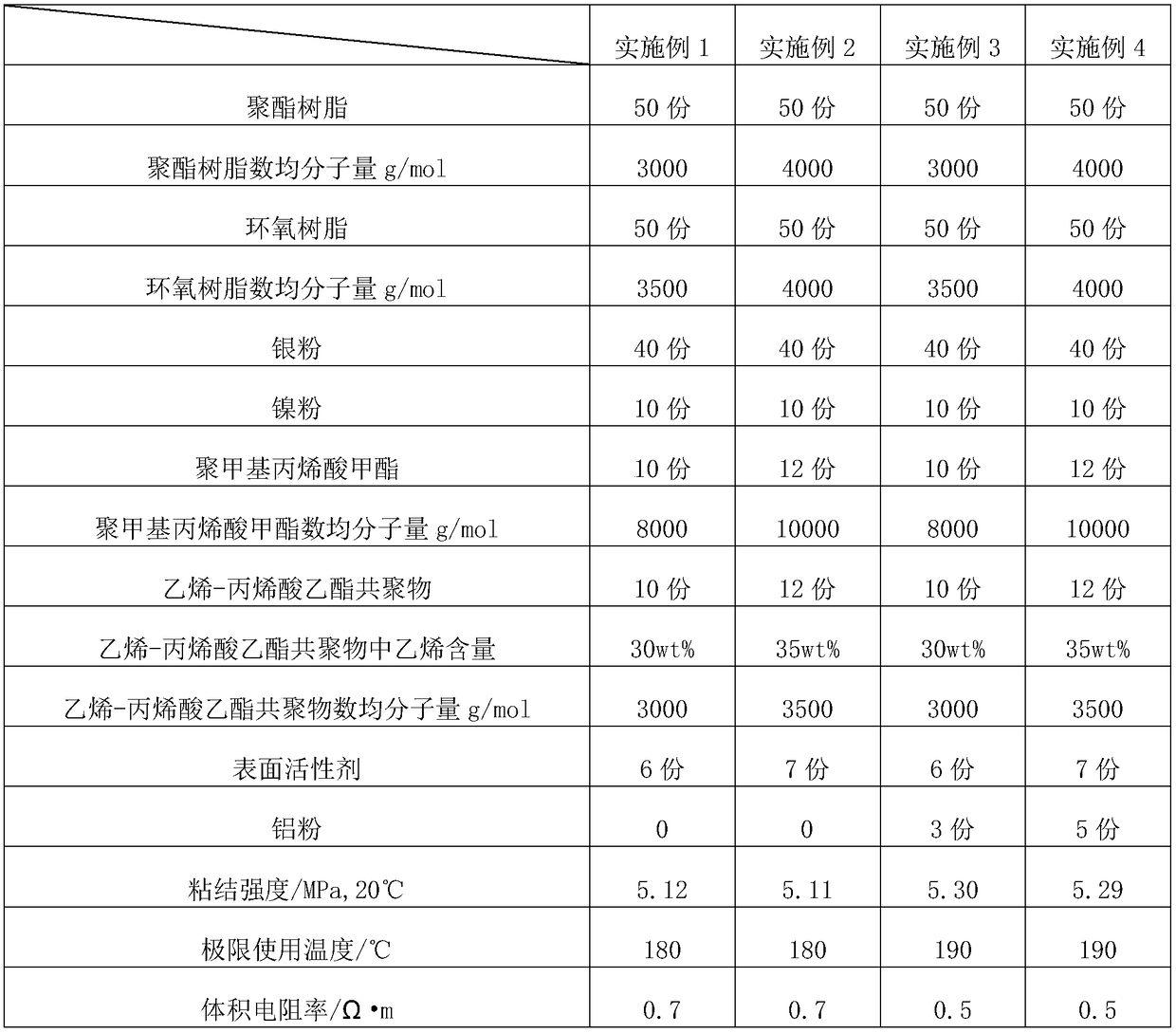

[0015] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

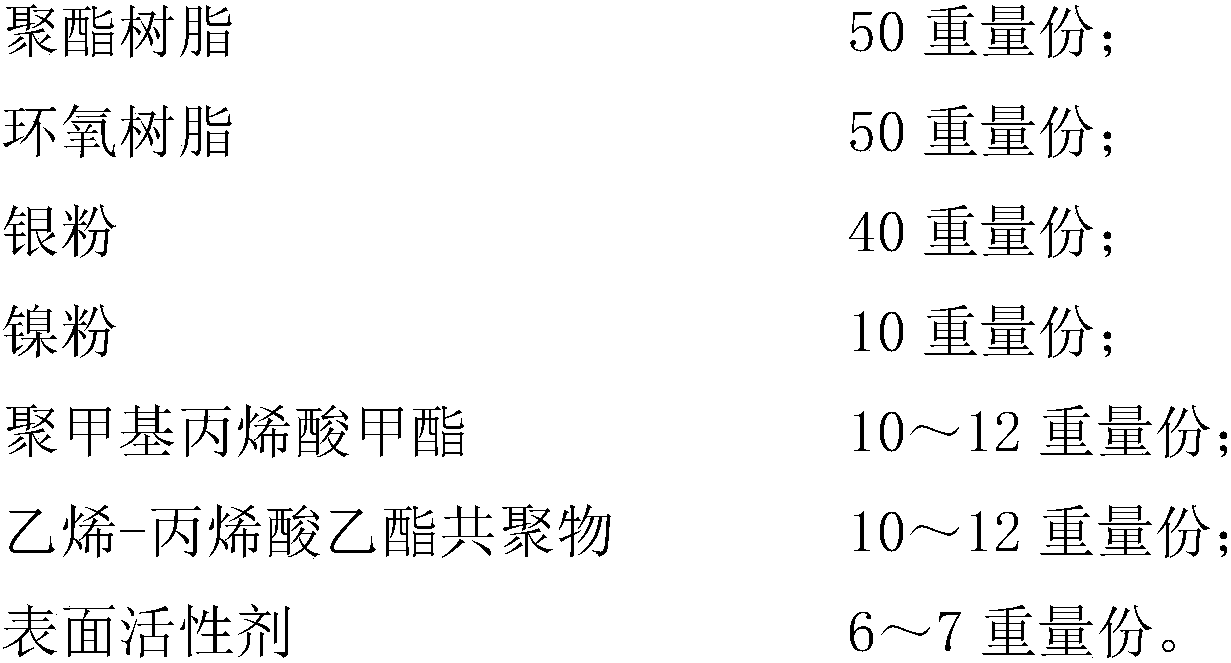

[0016] This case proposes the high-temperature-resistant conductive silver glue for producing LEDs of an embodiment, which includes the following materials by weight:

[0017]

[0018] Among them, the number average molecular weight of the polyester resin is preferably 3000-4000 g / mol.

[0019] Among them, the number average molecular weight of the epoxy resin is preferably 3500-4000 g / mol.

[0020] Among them, the number average molecular weight of polymethyl methacrylate is preferably 8000-10000 g / mol.

[0021] Among them, in the ethylene-ethyl acrylate copolymer, the content of ethylene is preferably 30-35wt%.

[0022] Among them, the number average molecular weight of the ethylene-ethyl acrylate copolymer is preferably 3000-3500 g / mol.

[0023] Among them, it is also pre

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap