Combined cutting tool applied to nickel starting sheet preparation unit nail lugs

A technology of combining cutting tools and starting plates, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as uneven riveting, easy passivation deformation, small amount of flanging, etc., to achieve smooth riveting edges, easy to solve Effect of long nickel bump and reduction of punching resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

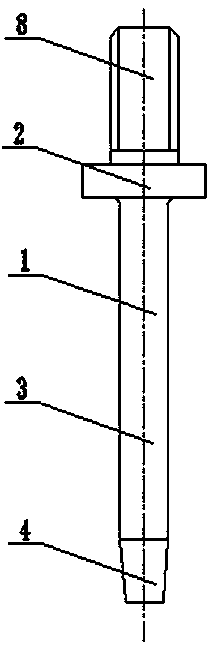

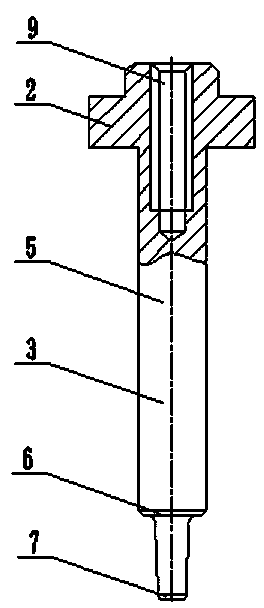

[0011] As shown in the figure, a combined tool applied to the nail ear of the nickel starting plate preparation unit includes a punching knife 1 and a riveting knife 5, and the punching knife 1 is divided into a supporting part 2, a connecting part 3 and a punching part 4, so that The rivet 5 is divided into a supporting part 2, a connecting part 3, a flattening part 6 and a flanging part 7; 6 is a cylinder. The punching knife 1 and the rivet 5 are respectively provided with a positioning screw 8 and a positioning screw hole 9 . The size of the rivet 5 is larger than that of the punching knife 1, and the rivet 5 is more suitable for opening the positioning screw hole 9.

[0012] When in use, the punching knife 1 and the riveting knife 5 are respectively connected to the piston rod of the hydraulic cylinder through the positioning screw 8 and the positioning screw hole 9, and the hydraulic cylinder is used to drive the punching knife 1 to punch holes on the nickel starting plate

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap