Gas-liquid converting stable borehole liquid for well drilling as well as preparation method thereof

A technology of gas-liquid conversion and wellbore stabilization, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of continuity, thin protective layer anti-scouring ability, uneven coverage of protective layer, etc., and achieve reasonable viscosity control , Reduce downhole complexity and improve drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A gas-liquid conversion well wall stabilizing fluid for oil industry drilling, consisting of the following components by weight percentage:

[0046] 1.0 # Diesel 30%;

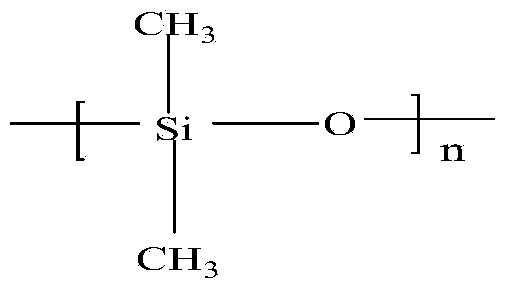

[0047] 2. Polydimethylsiloxane (number average molecular weight is 1000) 10%;

[0048] 3. Didodecyldimethylammonium chloride 10%;

[0049] 4. Sorbitan monoanhydride stearate 5%;

[0050] 5. Rosin modified phenolic resin 15%;

[0051] 6. Petroleum asphalt 5%;

[0052] 7. Polyethylene glycol (number average molecular weight is 5000) 5%;

[0053] 8. Deionized water 20%.

[0054] Technical indicators:

[0055] Apparent viscosity, mPa·s 14.0mPa·s;

[0056] Core linear expansion reduction rate% 95.4%;

[0057] Shale roll recovery % 99.7%.

[0058] The above experiments show that the preflush has good rheological properties and inhibition properties.

Embodiment 2

[0060] A gas-liquid conversion well wall stabilizing fluid for oil industry drilling, consisting of the following components by weight percentage:

[0061] 1.5 # White oil 45%;

[0062] 2. Polydimethylsiloxane (number average molecular weight 5000) 8%;

[0063] 3. Didodecyldimethylammonium chloride 7%;

[0064] 4. Sorbitan monoanhydride oleate 2%;

[0065] 5. Rosin modified phenolic resin 13%;

[0066] 6. Petroleum asphalt 10%;

[0067] 7. Polyethylene glycol (number average molecular weight 20000) 5%;

[0068] 8. Deionized water 10%.

[0069] Technical indicators:

[0070] Apparent viscosity, mPa·s 12.0mPa·s;

[0071] Core linear expansion reduction rate% 94.8%;

[0072] Shale roll recovery % 99.2%.

[0073] The above experiments show that the preflush has good rheological properties and inhibition properties.

Embodiment 3

[0075] A gas-liquid conversion well wall protection agent for oil industry drilling, consisting of the following components by weight percentage:

[0076] 1.5 # White oil 60%;

[0077] 2. Polydimethylsiloxane (number average molecular weight 3000) 3%;

[0078] 3. Dihexadecyldimethyl ammonium chloride 5%;

[0079] 4. Sorbitan monoanhydride oleate 2%;

[0080] 5. Rosin modified phenolic resin 10%;

[0081] 6. Petroleum asphalt 5%;

[0082] 7. Polyethylene glycol (number average molecular weight 10000) 10%;

[0083] 8. Deionized water 5%.

[0084] Technical indicators:

[0085] Apparent viscosity, mPa·s 10.0mPa·s;

[0086] Core linear expansion reduction rate% 94.2%;

[0087] Shale Roll Recovery % 98.9%.

[0088] The above experiments show that the preflush has good rheological properties and inhibition properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap