Pipe shed for reinforcing rock-soil layer

A technology of rock-soil layer and pipe shed, which is applied in the fields of soil protection, construction, and infrastructure engineering, etc. It can solve problems such as low stiffness, high safety requirements for disturbance effects, and difficulty in meeting the small displacement control requirements of adjacent structures. The effect of soil reinforcement and counteracting the loss of ground stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention are described in detail below, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

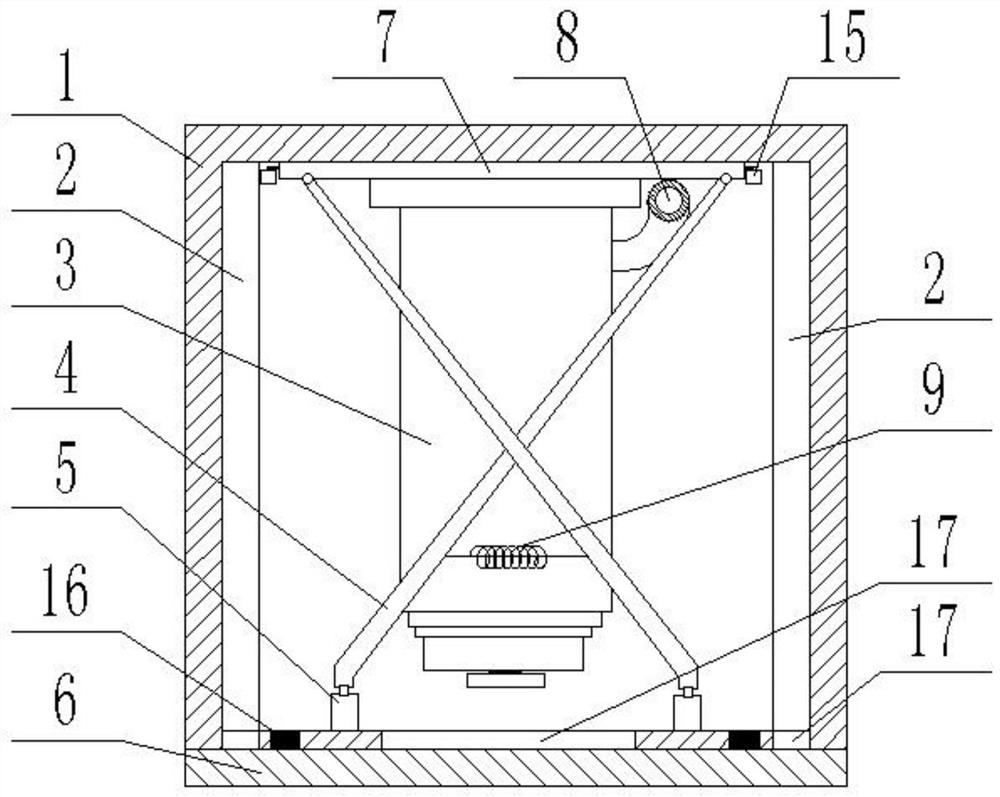

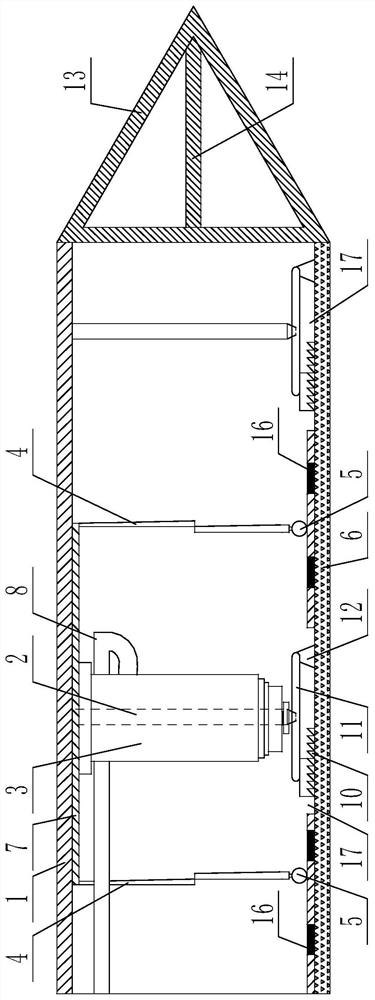

[0020] A pipe shed for rock and soil layer reinforcement provided by the invention, such as Figure 1-2 It includes: a pipe body 1, a supporting structure and a plurality of reinforcing columns 2. The bottom wall of the pipe body 1 is provided with a plurality of first through holes 17, and the outer wall of the bottom is close to the bottom plate 6; the supporting structure includes a top plate 7, a lifting device 3 and four The support rod 4 and the top plate 7 are close to the top inner wall of the pipe body 1. The top plate 7 is hinged to the tops of the two suppo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap