Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

21 results about "Sewing machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

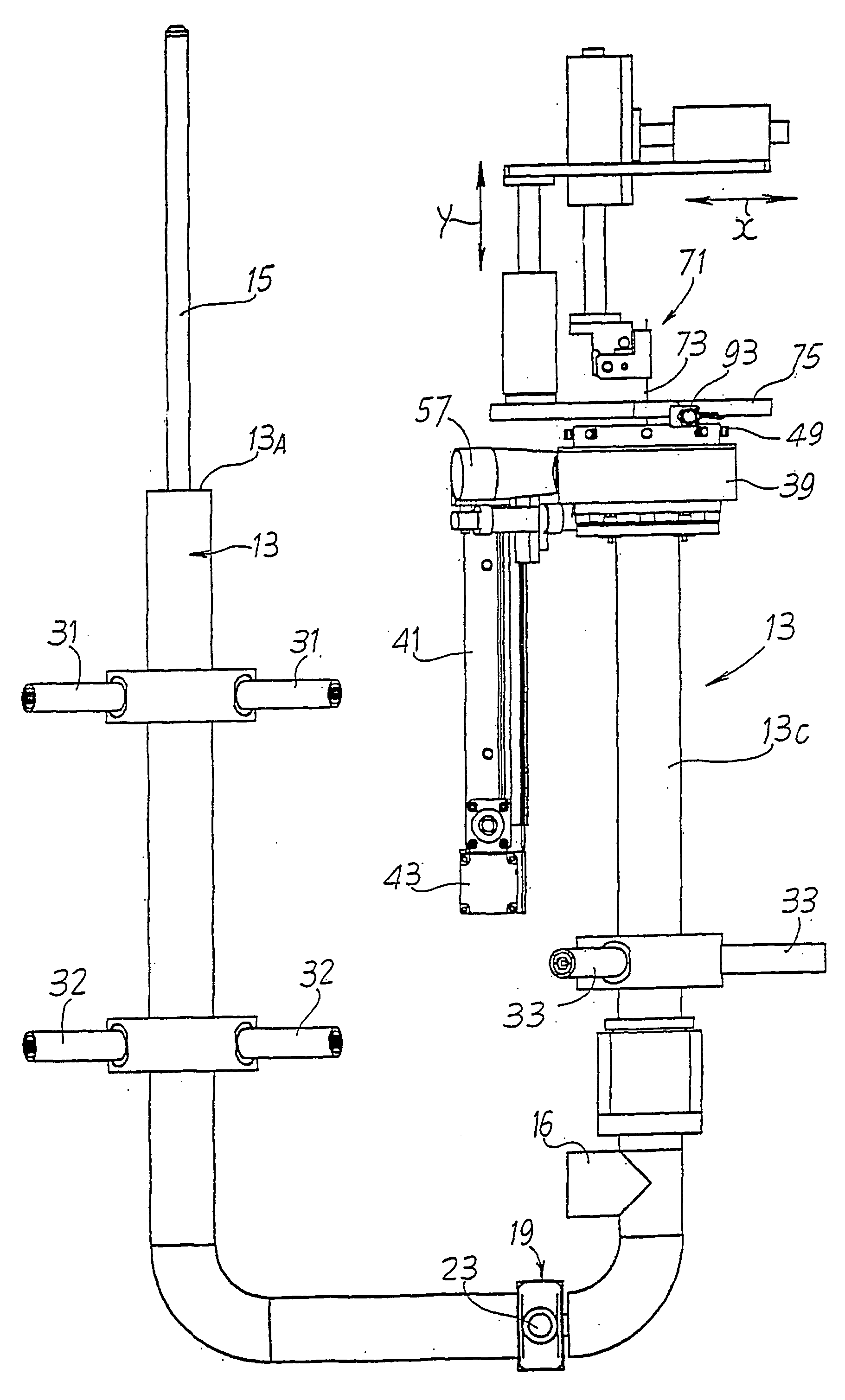

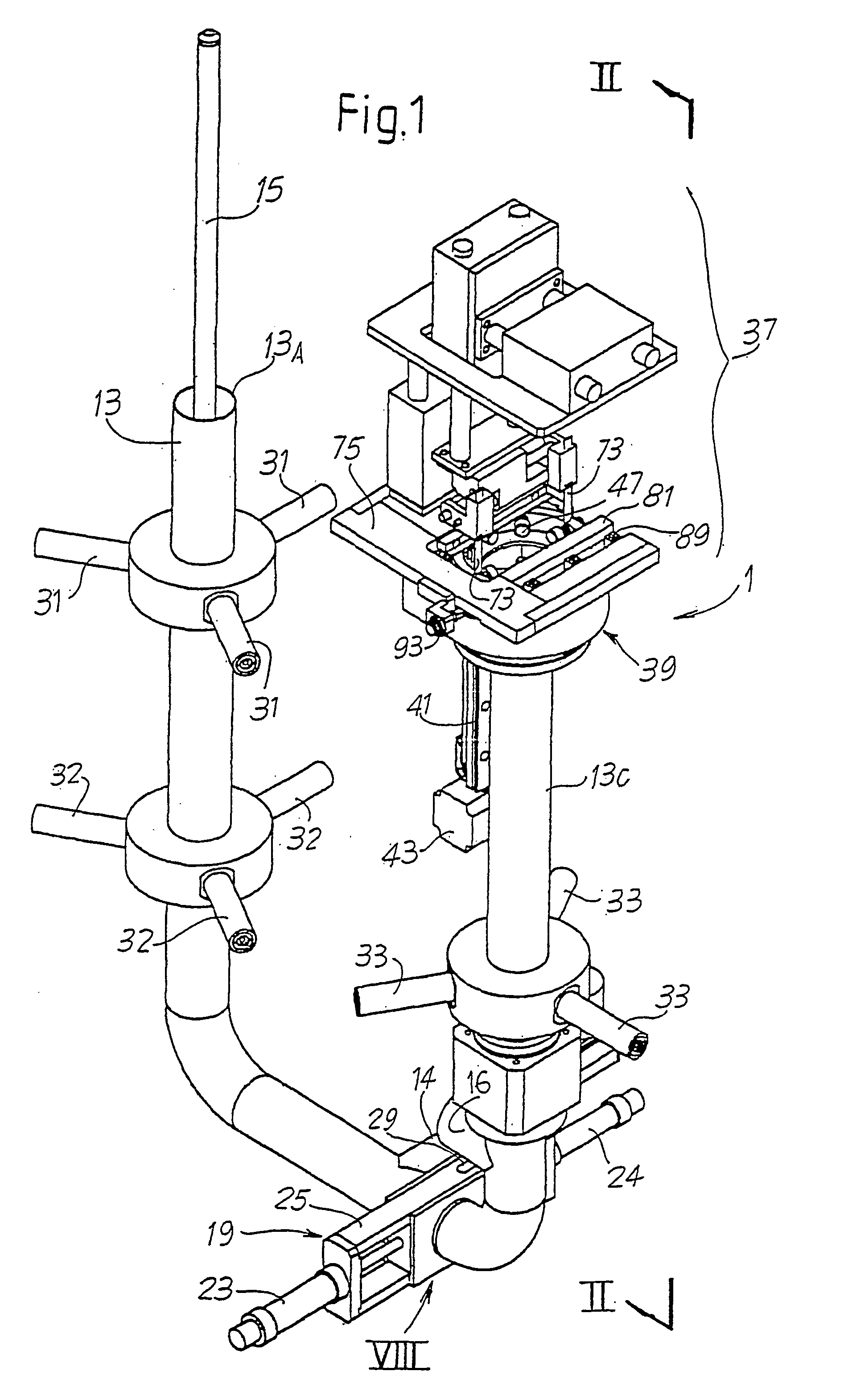

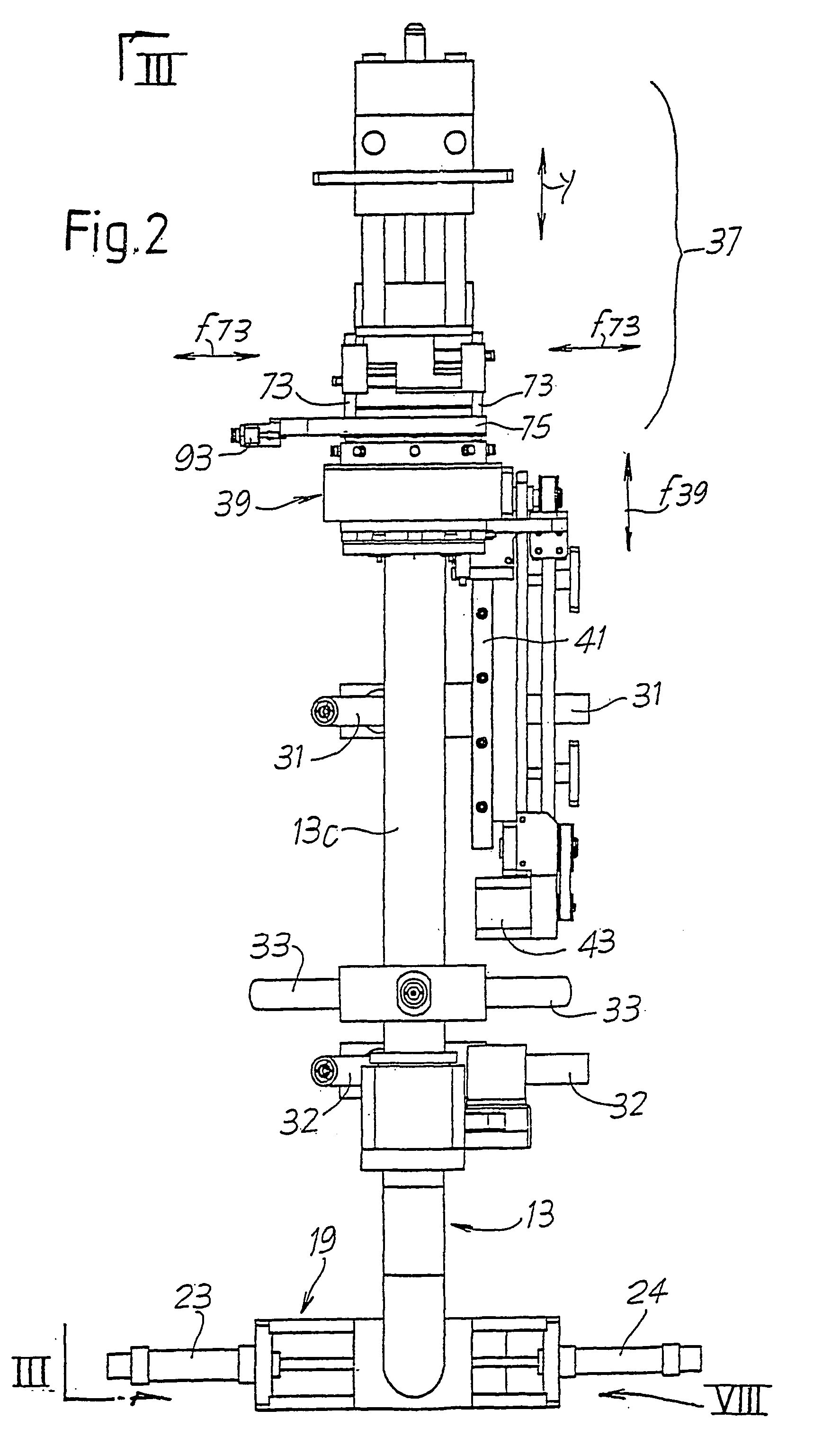

Device for picking up a tubular knitted article from a knitting machine and for sewing the toe

InactiveUS20040154341A1Easy to operateSimple designMechanical cleaningPressure cleaningEngineeringSewing machine

Owner:GOLDEN LEDI CO SPA

Surface layer abrasion-proof paper

ActiveCN101148849AHighly transparentExtended service lifeSpecial paperPaper/cardboardSurface layerWear resistant

The surface wear resistant paper for making decorating thermosetting laminated sheet contains stuffing and assistant. It has high transparency, high wear resistance, long service life, environment friendship and other advantages. It is applied widely for the surface of furniture, vehicle, ship, airplane, floor, instrument, etc.

Owner:SHANDONG QIFENG SPECIAL PAPER

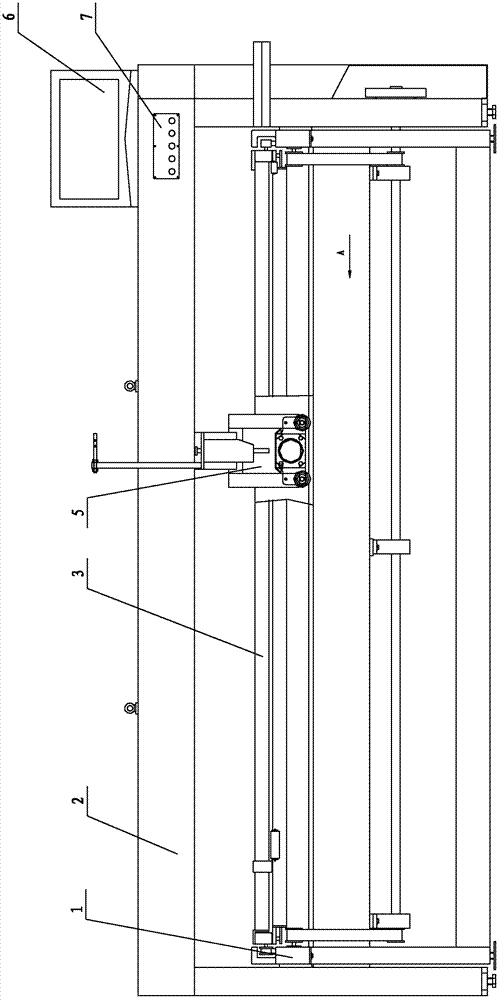

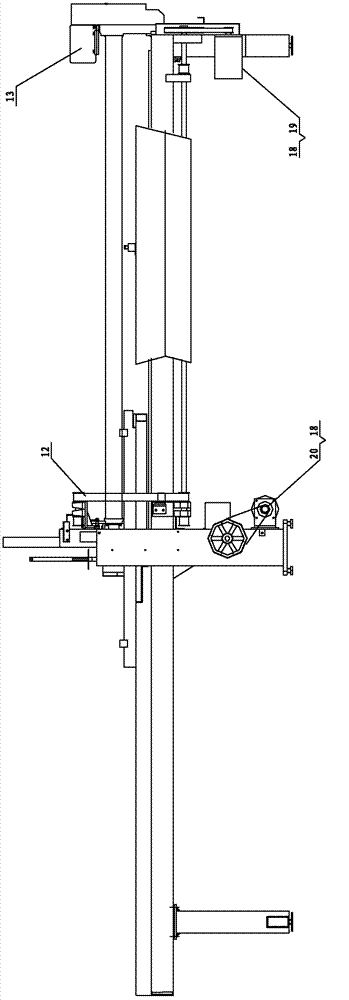

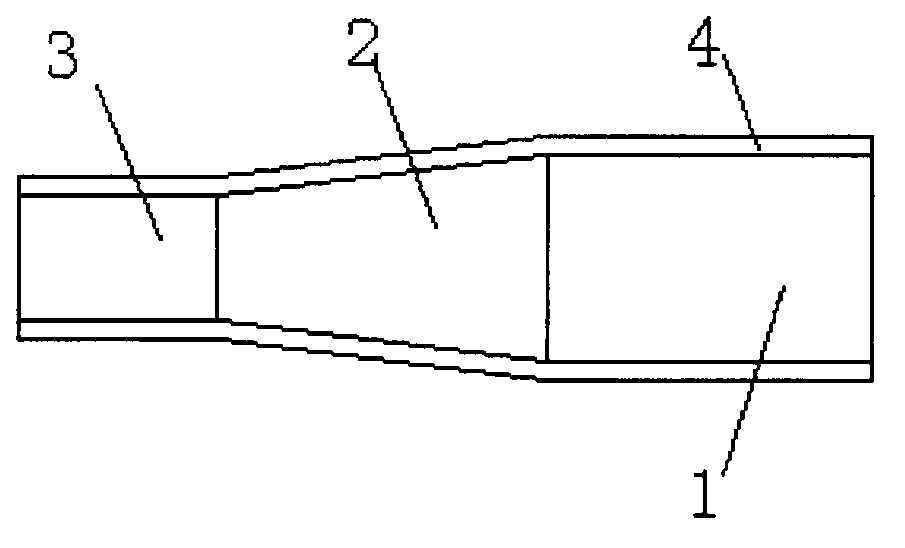

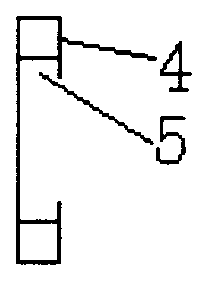

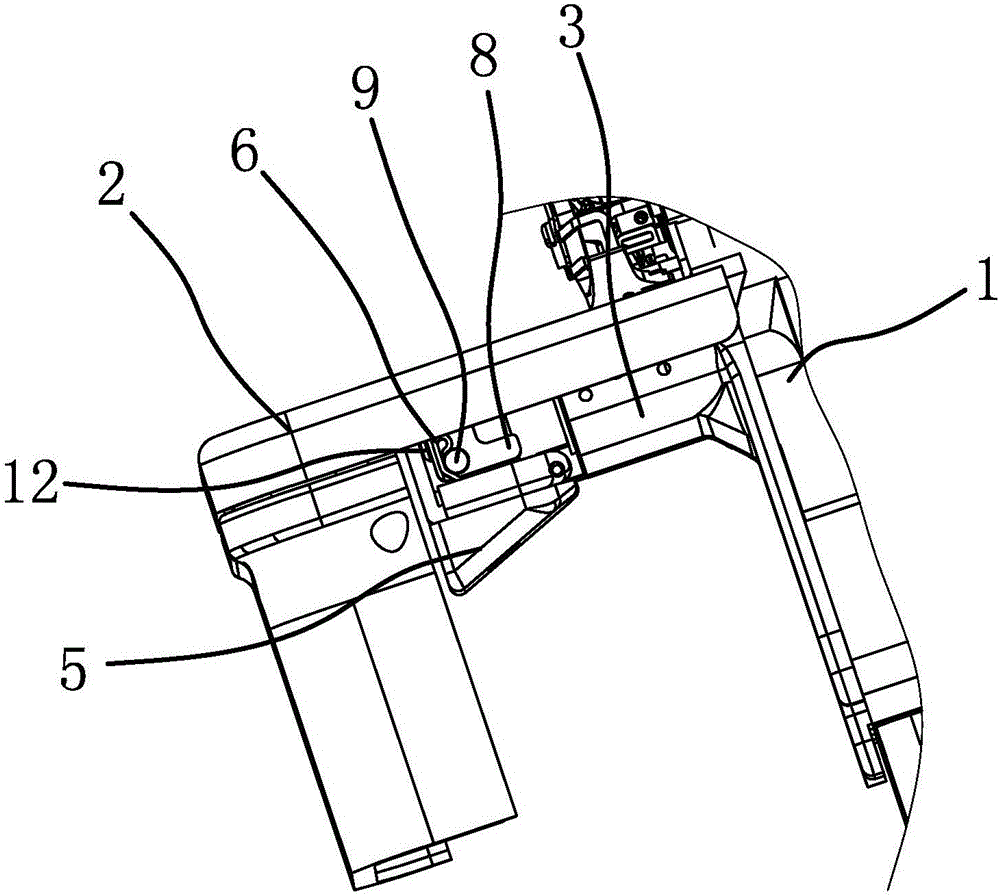

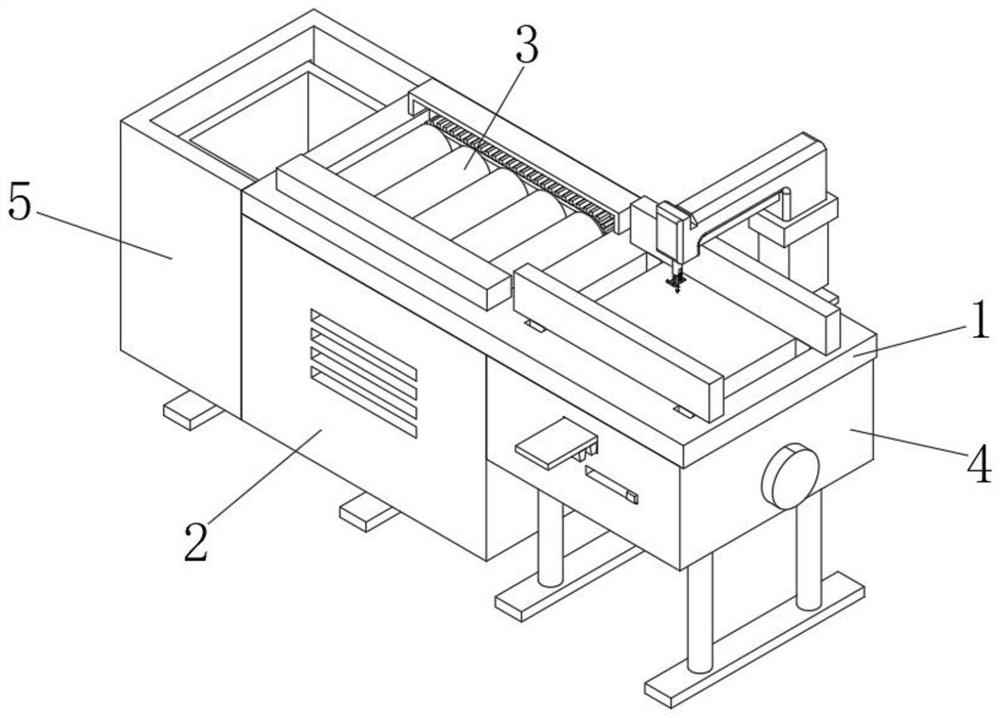

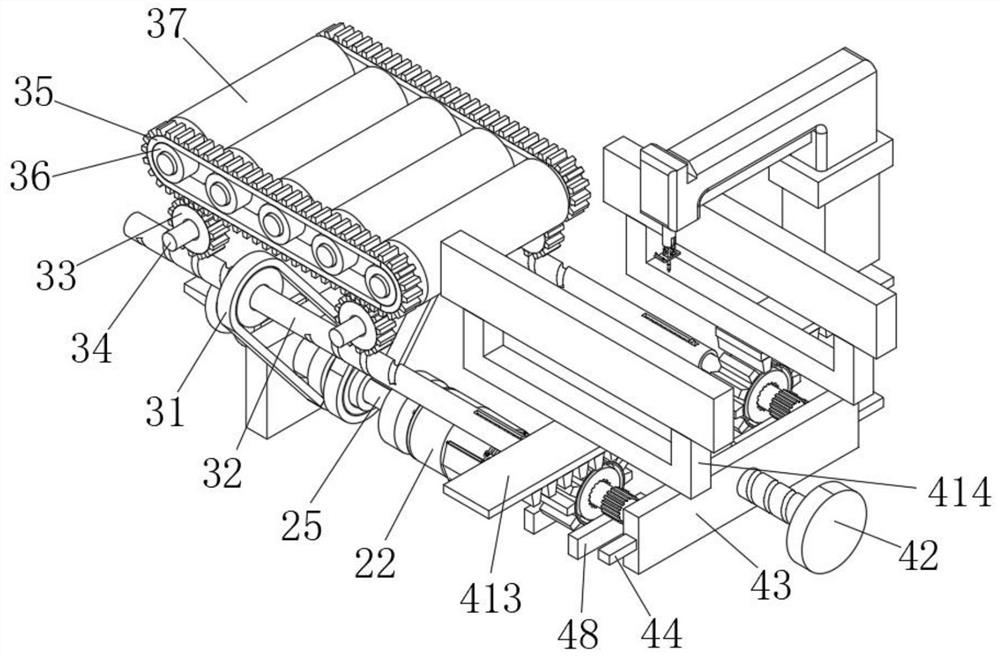

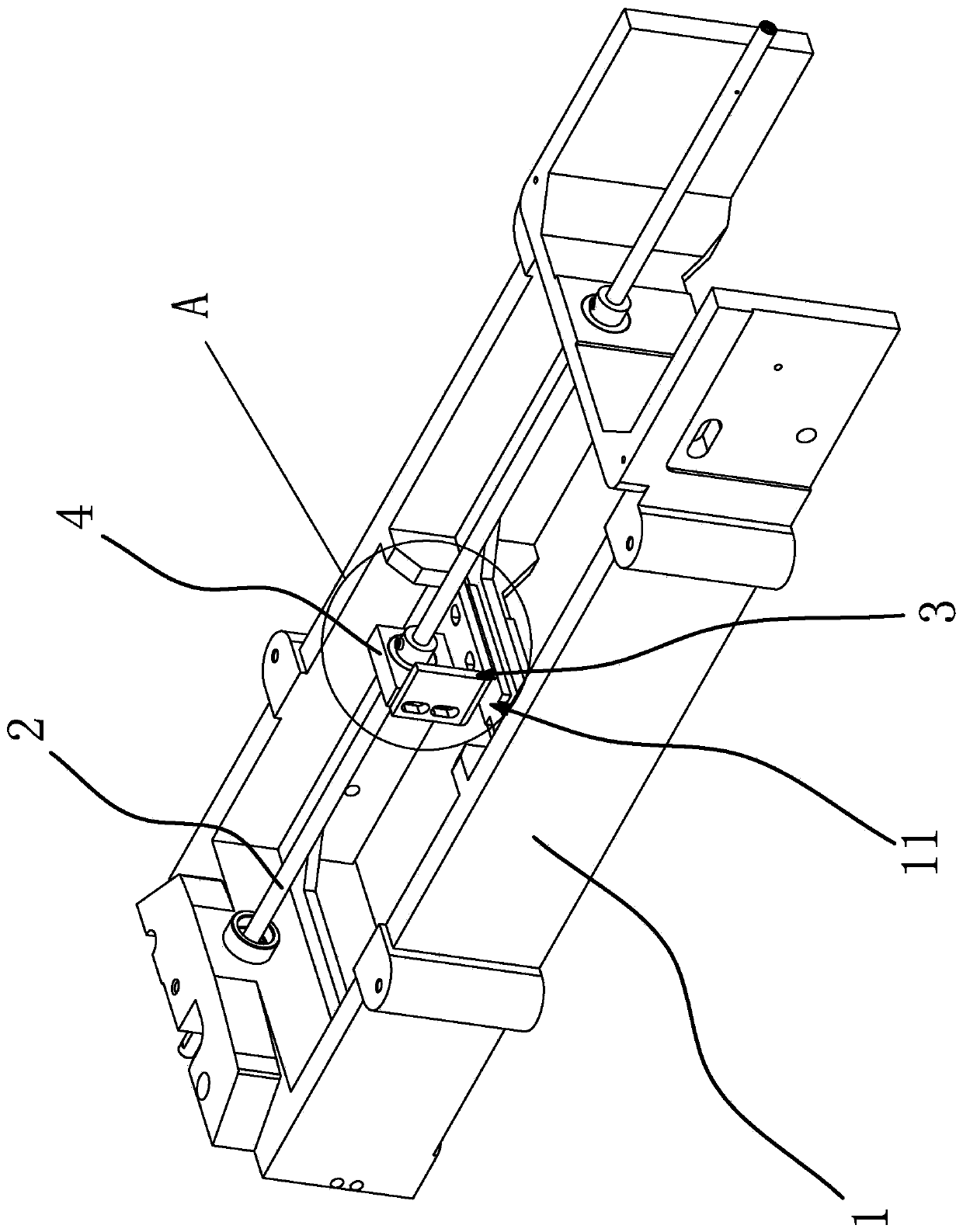

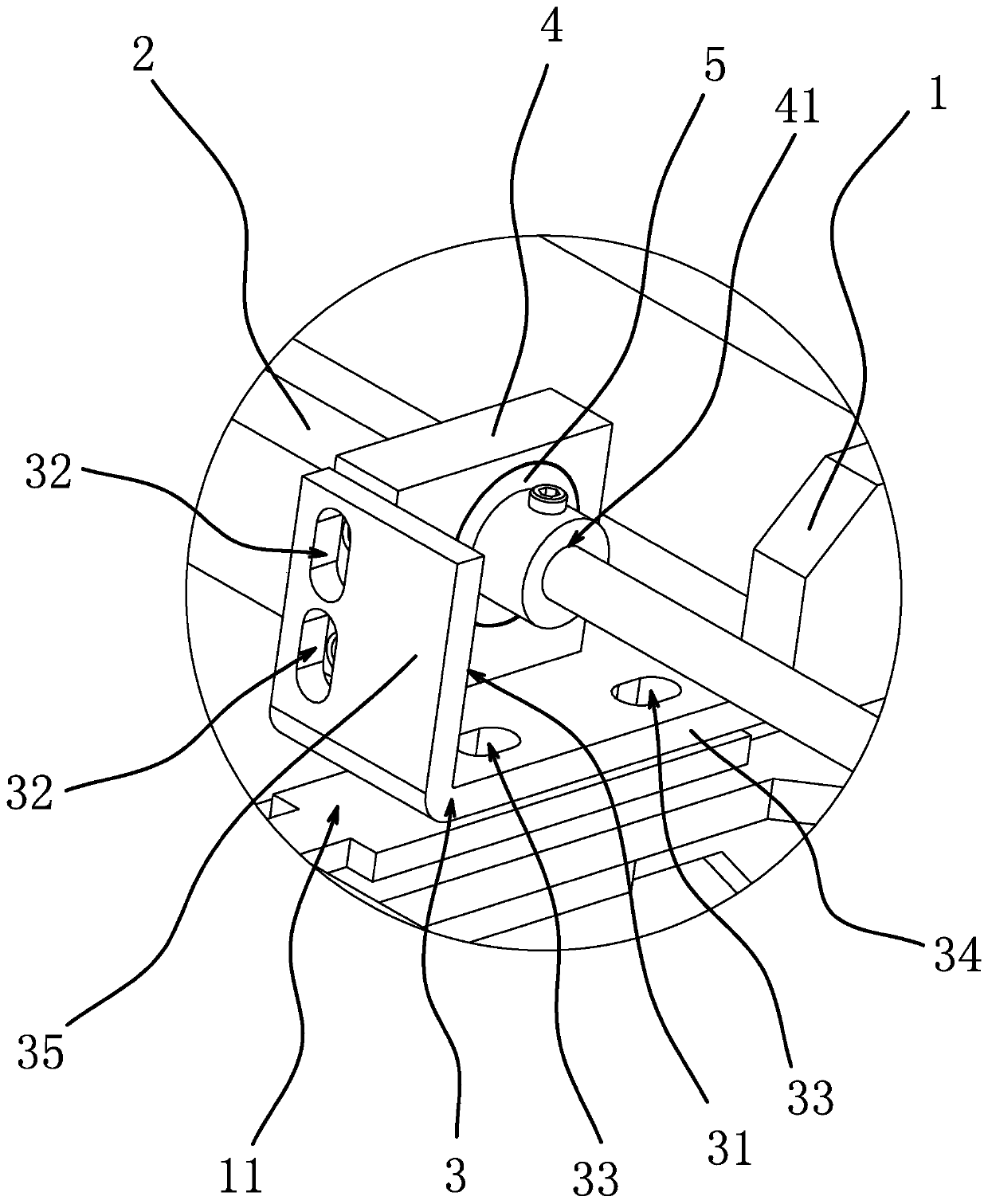

Cloth feeding mechanism for eyelet button hole sewing machine

ActiveCN106436045AEnsure safetyGuaranteed stabilityWork-feeding meansSewing-machine control devicesGear wheelPinion

The invention relates to a cloth feeding mechanism for an eyelet button hole sewing machine. The cloth feeding mechanism for the eyelet button hole sewing machine comprises an electric motor (1), a pinion (2), a gear wheel (3), a gear shaft (4) and a cloth feeding table (5); an output shaft of the electric motor (1) is fixedly connected with the pinion (2); the gear wheel (3) is in engaged transmission connection with the pinion (2); engaging teeth which can be in engaged transmission connection with the engaging teeth of the gear wheel (3) are formed on the gear shaft (4); the engaging teeth on the gear shaft (4) are in engaged transmission connection with the engaging teeth on the gear wheel (3) to drive the gear shaft (4) to move; one end of the gear shaft (4) is connected with the cloth feeding table (5). According to the cloth feeding mechanism provided by the invention, the cloth feeding table is driven to move and perform a cloth feeding operation by adopting the engaged transmission between the pinion and the gear wheel and the mode of driving the gear shaft to move; the service life is greatly prolonged; the cloth feeding mechanism is durable in use.

Owner:闫瑞东

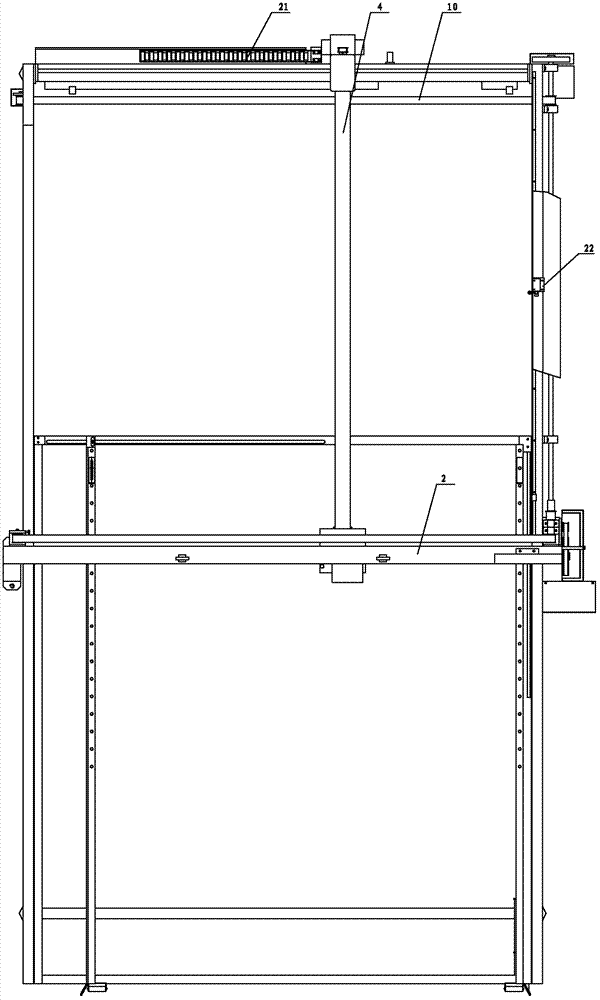

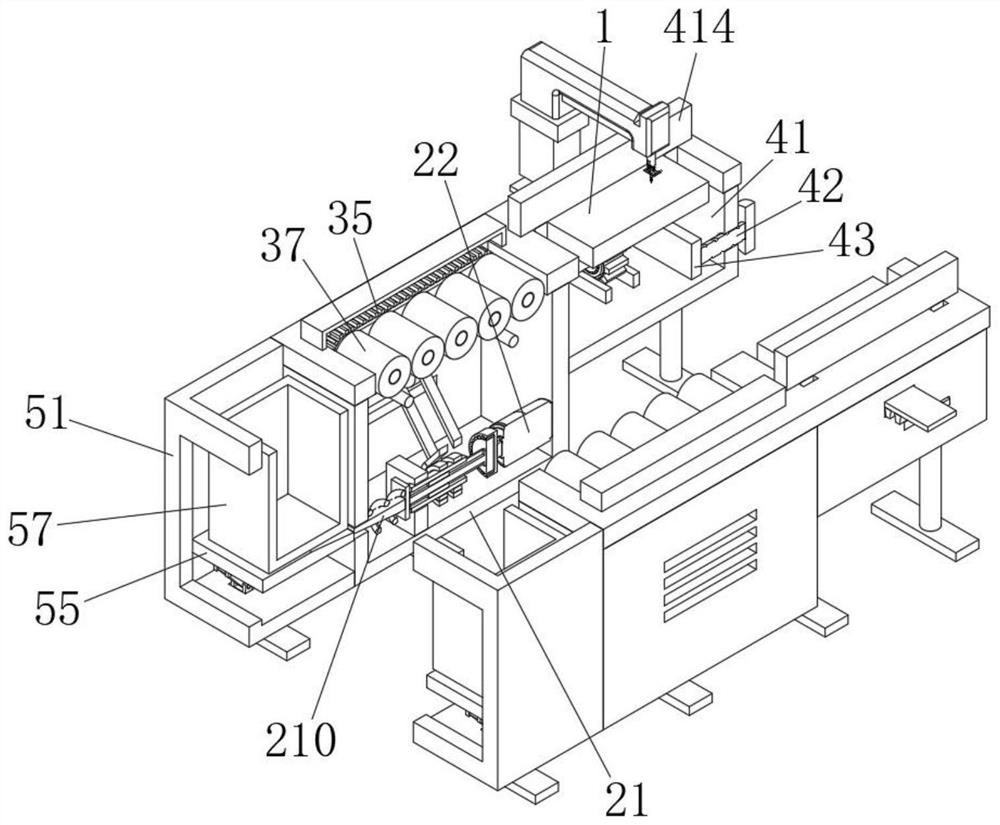

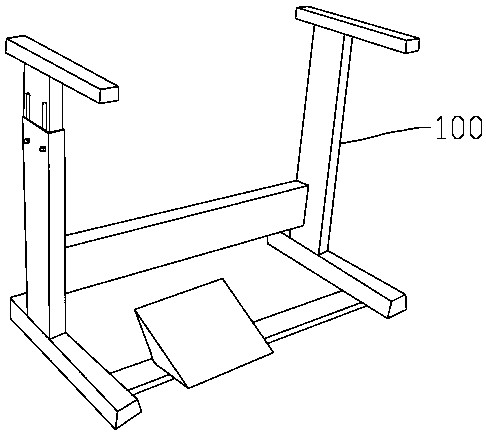

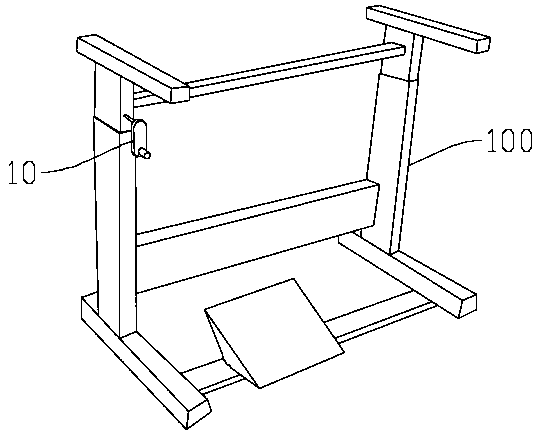

Tightening machine capable of automatically correcting position of bottom plate of sewing machine shell

InactiveCN113182829AIncrease productivityAvoid assembly errorsMetal working apparatusPush and pullReciprocating motion

The invention relates to a tightening machine capable of automatically correcting the position of a bottom plate of a sewing machine shell. The tightening machine is characterized in that the tightening machine comprises a rack and a fixture for positioning and clamping the machine shell and the bottom plate; the rack is provided with a floating mechanism for positioning the position of the bottom plate, a tightening mechanism for assembling the machine shell and the bottom plate, a material pushing and pulling device for driving a workpiece to reciprocate between a feeding station and a tightening station, a measuring device for measuring the position of the bottom plate of the machine shell and a driving device for adjusting the position of the machine shell; the driving device is used for driving the machine shell fixture to adjust the position of the machine shell according to a measured value of the measuring device; and the floating device is used for converting the positioning reference of the fixture into the assembling reference of the tightening mechanism. The reference is converted through the floating device, and the positioning reference sum of the fixture is converted into the assembling positioning reference. Compared with an existing manual assembly mode, the production efficiency is greatly improved, meanwhile, assembly errors are avoided, and large-scale production can be achieved; and moreover, parts with different sizes can be used, and the universality is good.

Owner:DONGFENG EQUIP MFG CO LTD

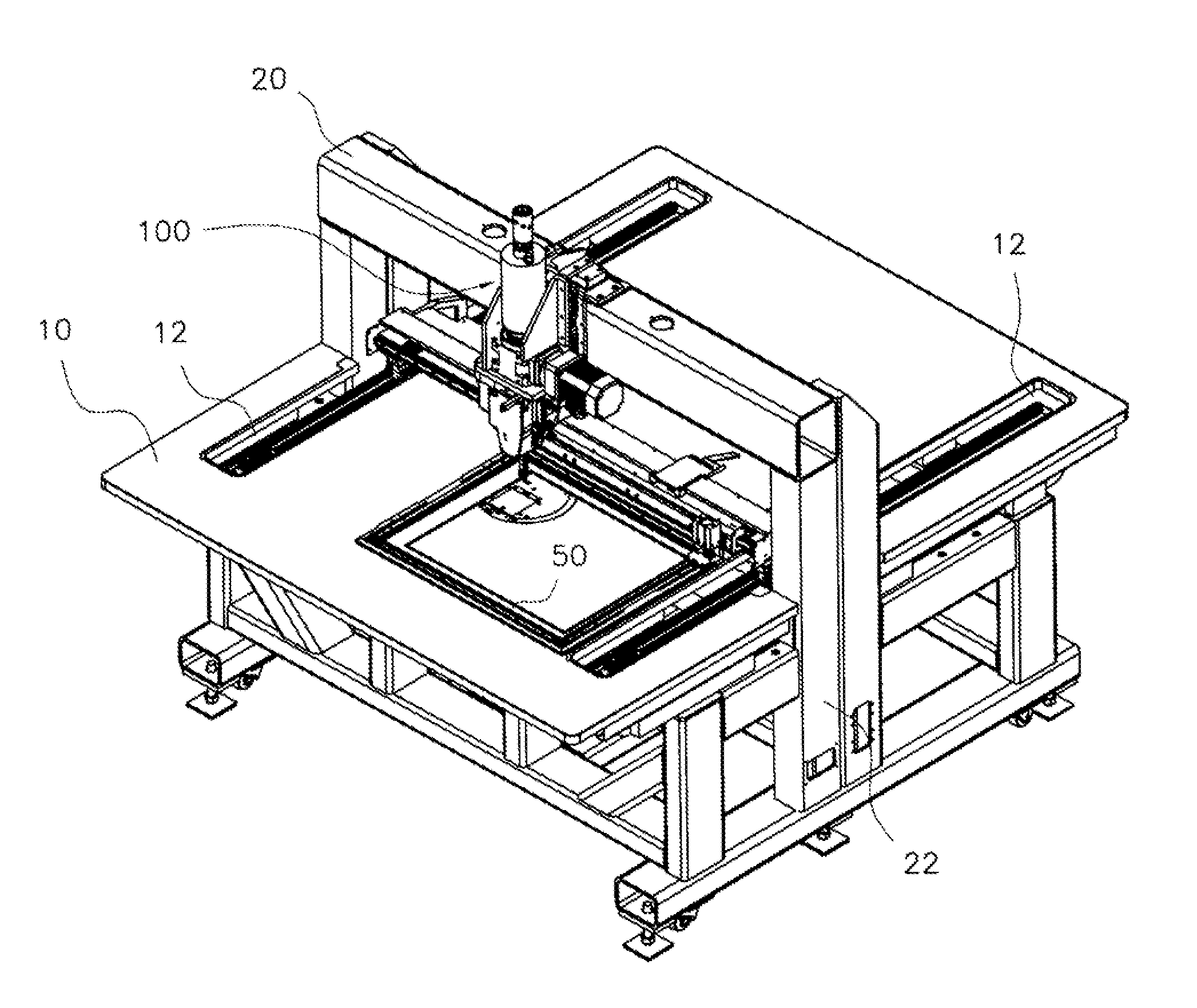

Computerized cushion sewing machine

InactiveCN102899809ASolving Consistency IssuesFix stability issuesProgramme-controlled sewing machinesSewing-machine control devicesDrive shaftEngineering

Owner:苏州市正步机器制造有限公司

Novel spool creel

Owner:青岛酷特智能股份有限公司

Jacket processing equipment

Owner:天津市宝坻区志远制衣有限公司

Automatic hemmer for sewing machine

Owner:常熟市辛庄镇金玉制衣厂

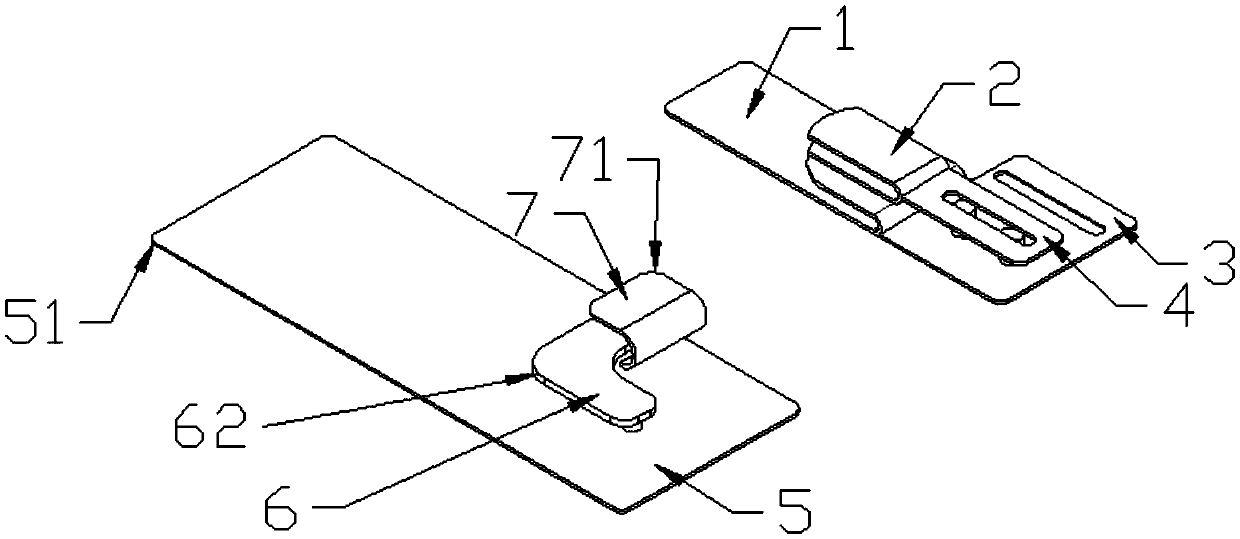

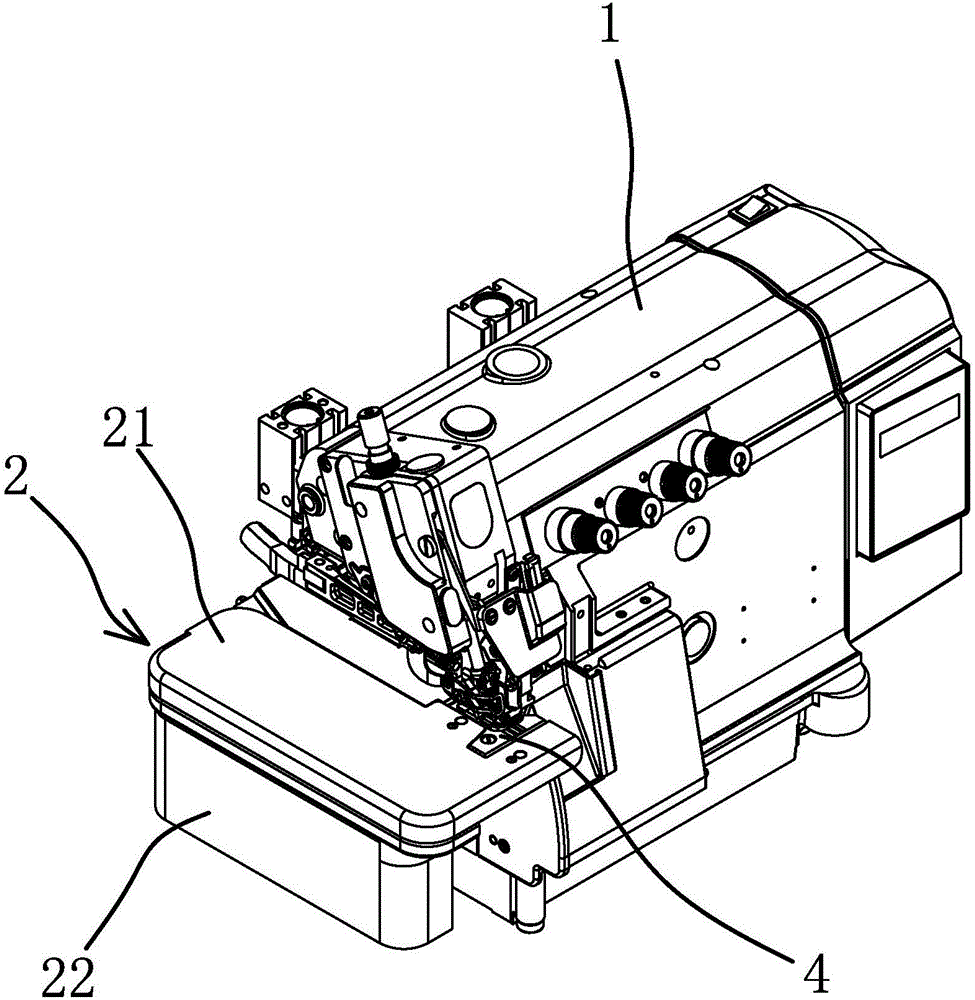

Overlock machine

ActiveCN106757860AImprove versatilitySimple structureSewing-machine casingsManufacturing computing systemsEngineeringHinge joint

Owner:ZHEJIANG ZOJE SEWING MACHINE

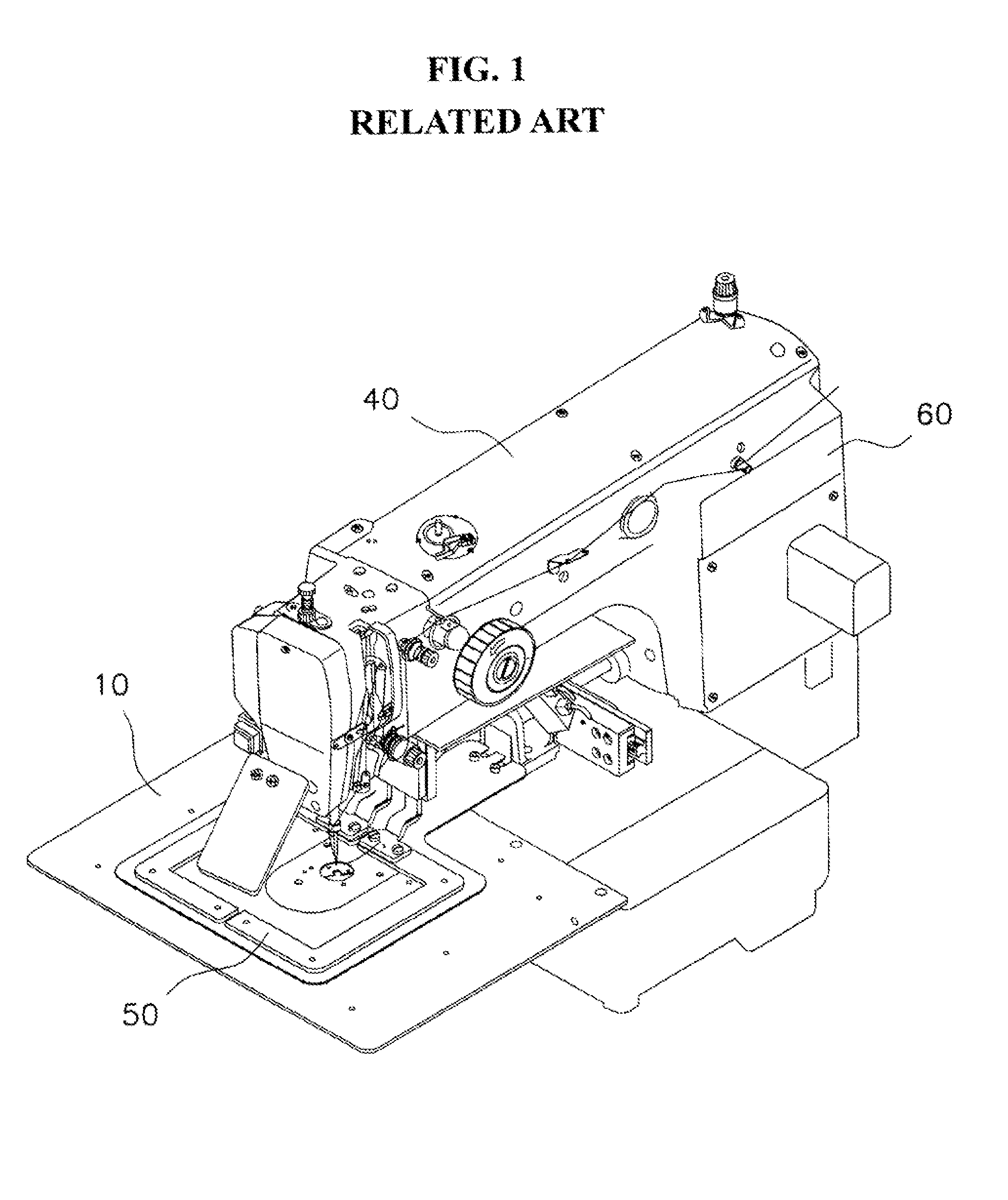

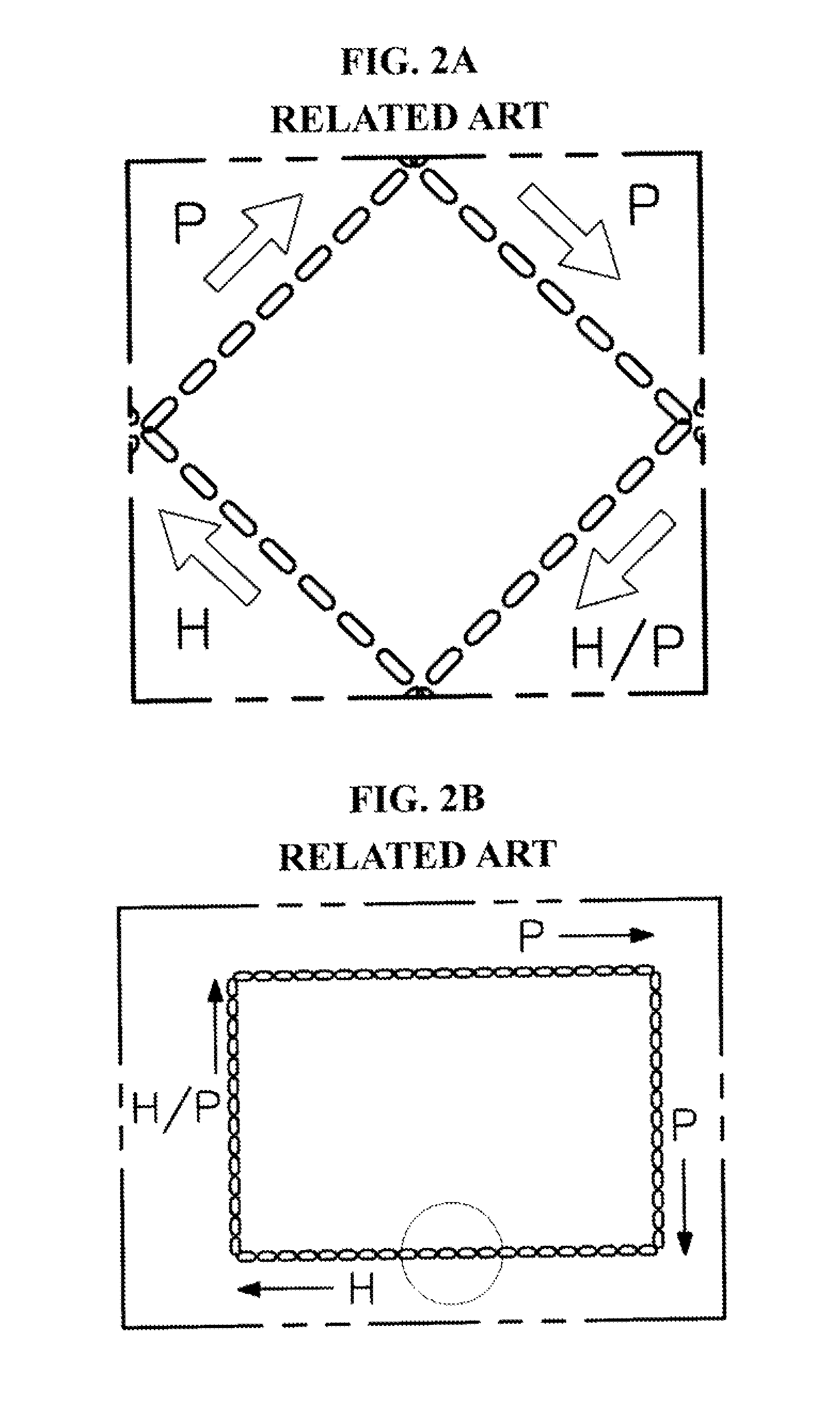

Sewing machine and method of controlling operation of the same

ActiveUS20120145061A1Improve product qualityEasy splicingLeather sewingSewing-machine control devicesEngineeringSewing machine

Owner:SUNSTAR KK

Sewing machine device for footwear processing and with edge distance deviation preventing structure

InactiveCN113046937AImprove processing efficiencyReduce stepsLeather sewingWork-feeding meansEngineeringMaterials processing

Owner:WENZHOU POLYTECHNIC

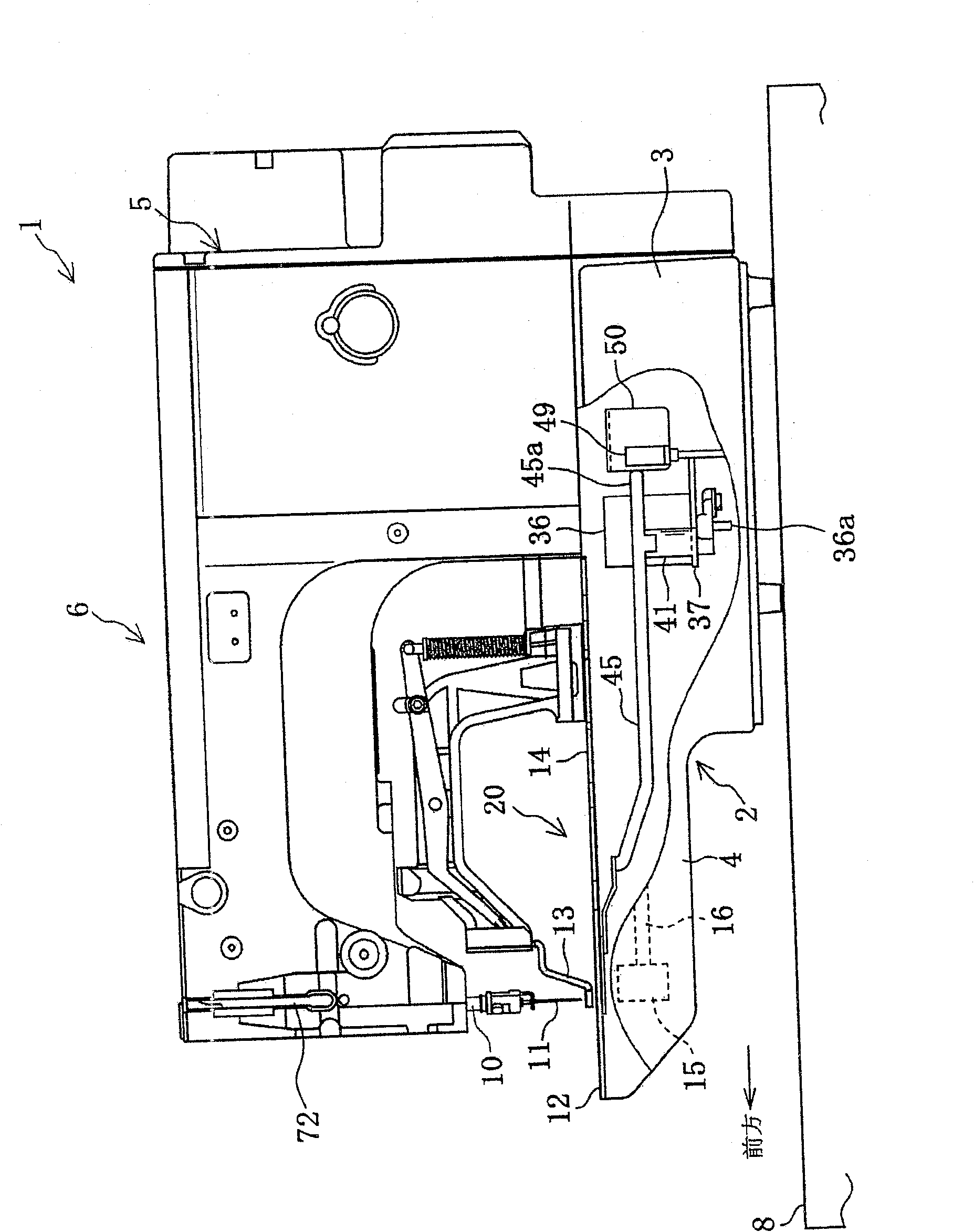

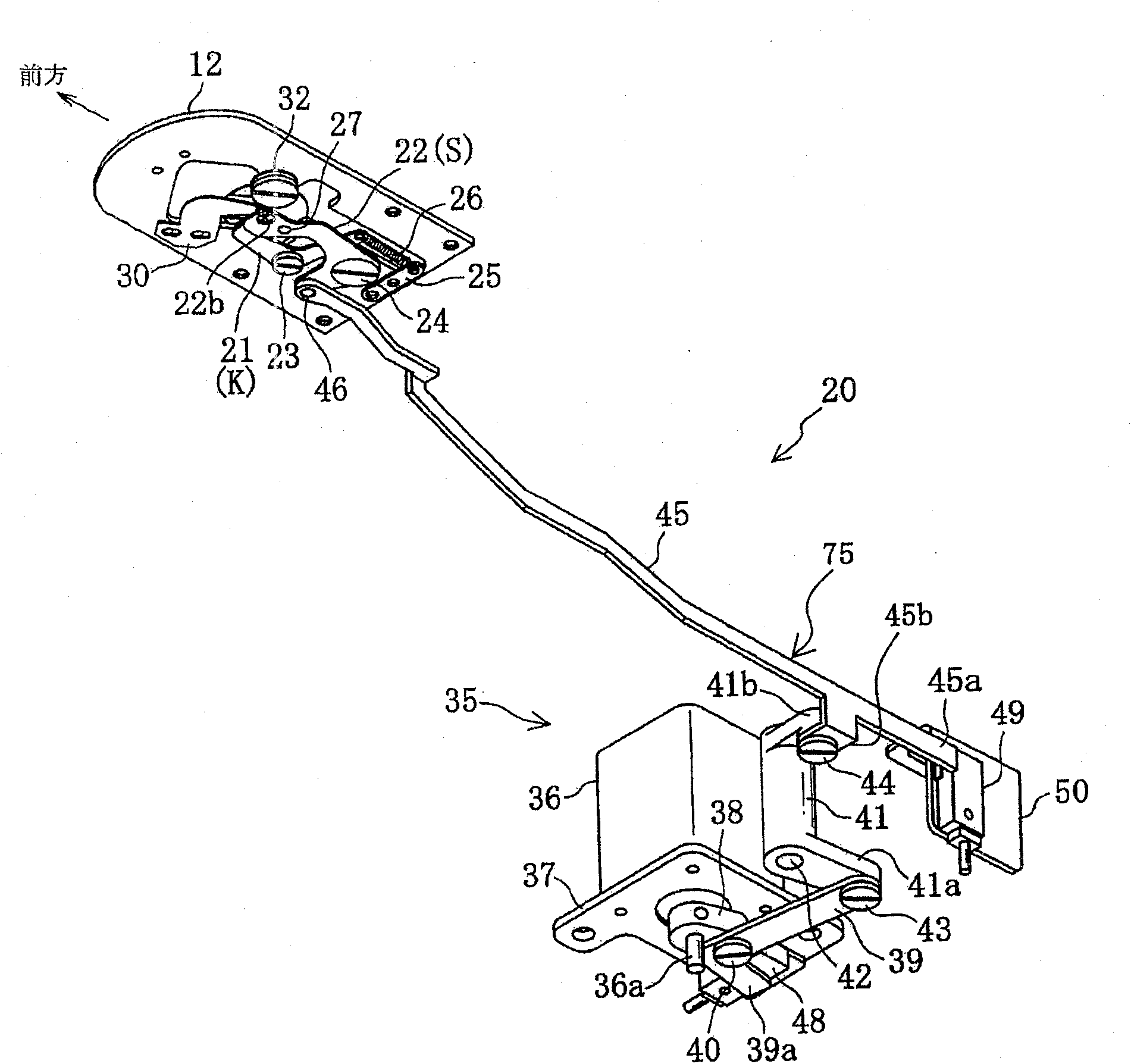

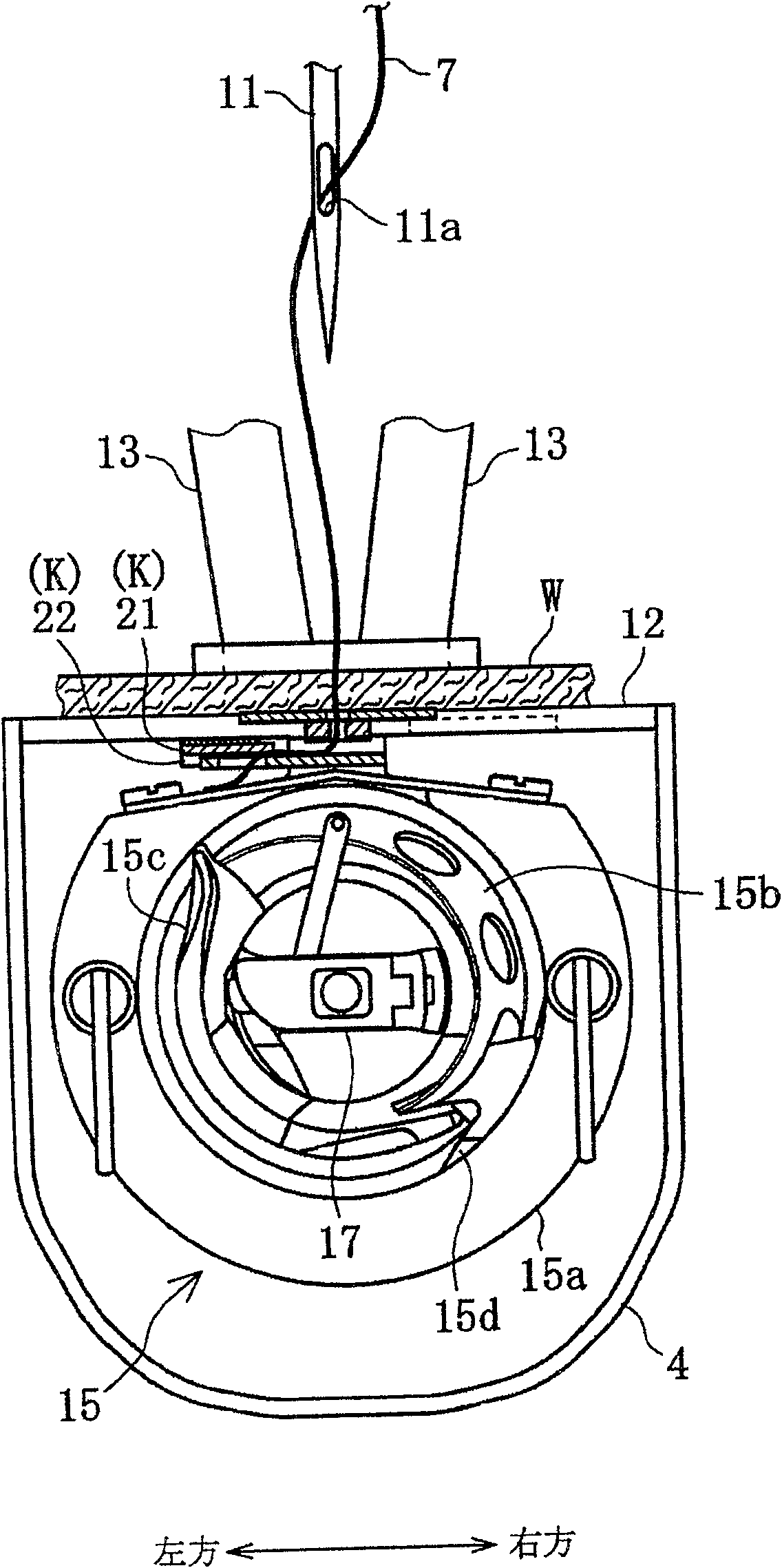

Threading holder of sewing machine

The invention relates to a threading holder of sewing machine. A second thread clamping plate 22 rotates among a starting position, a clamping position and a releasing position. The starting positionof the second thread clamping plate 22 is the position where its thread hole 22b overlaps the needle hole 12a of the throat plate 12. When the second thread clamping plate 22 is at the starting position, the needle 11 descends and enters to the thread hole 22b from the needle hole 12 and the needle 11 ascends and emerges to from the needle hole 12a to the thread hole 22b, and when the needle 11 emerges out, the thread end section 7a of thread 7 is in its thread hole 22b of the second thread clamping plate 22. The clamping position is the position where its thread hole 22b overlaps the inferiorof the first thread clamping plate 21. When the second thread clamping plate 22 rotates to the clamping position, the thread end section 7a is clamped between the second thread clamping plate 22 andfirst thread clamping plate 21. A releasing position is the position where the thread hole 22b is locally opened. When the second thread clamping plate 22 moves to the releasing position, the clamp ofthe thread end section 7a is released.

Owner:BROTHER KOGYO KK

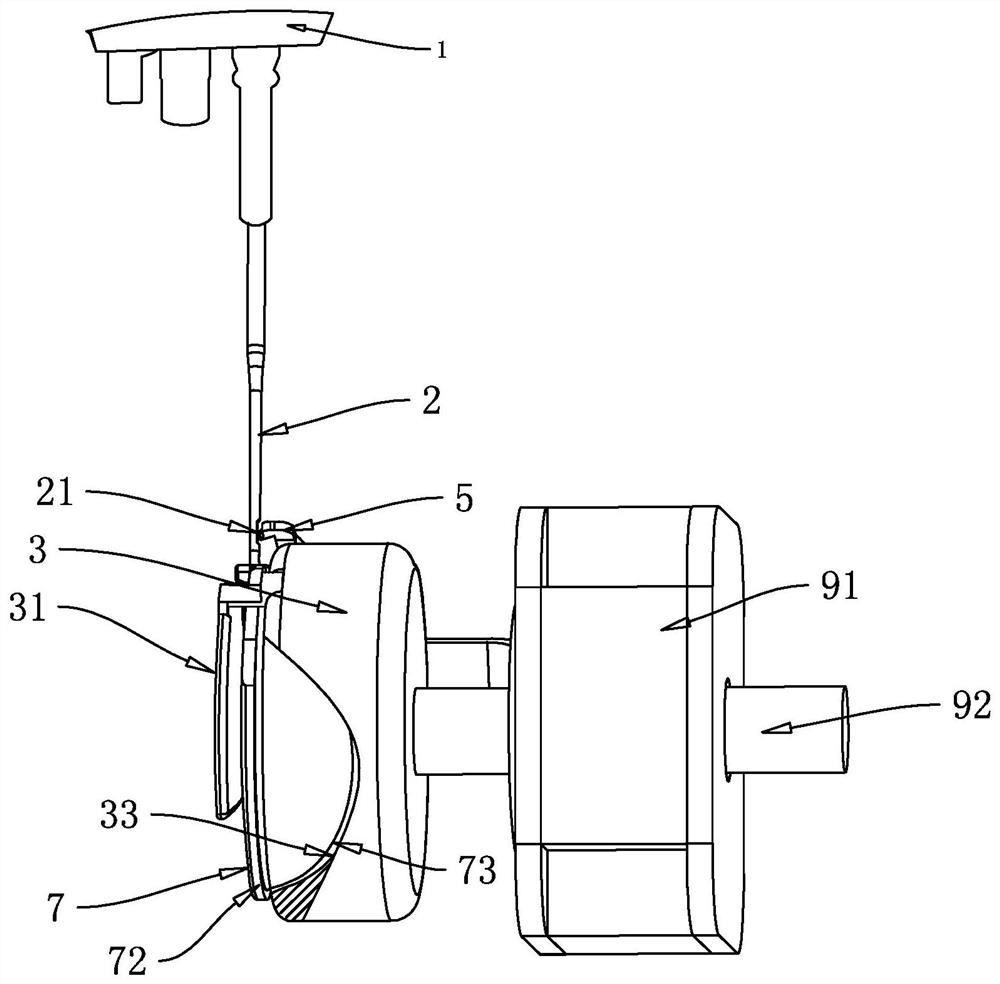

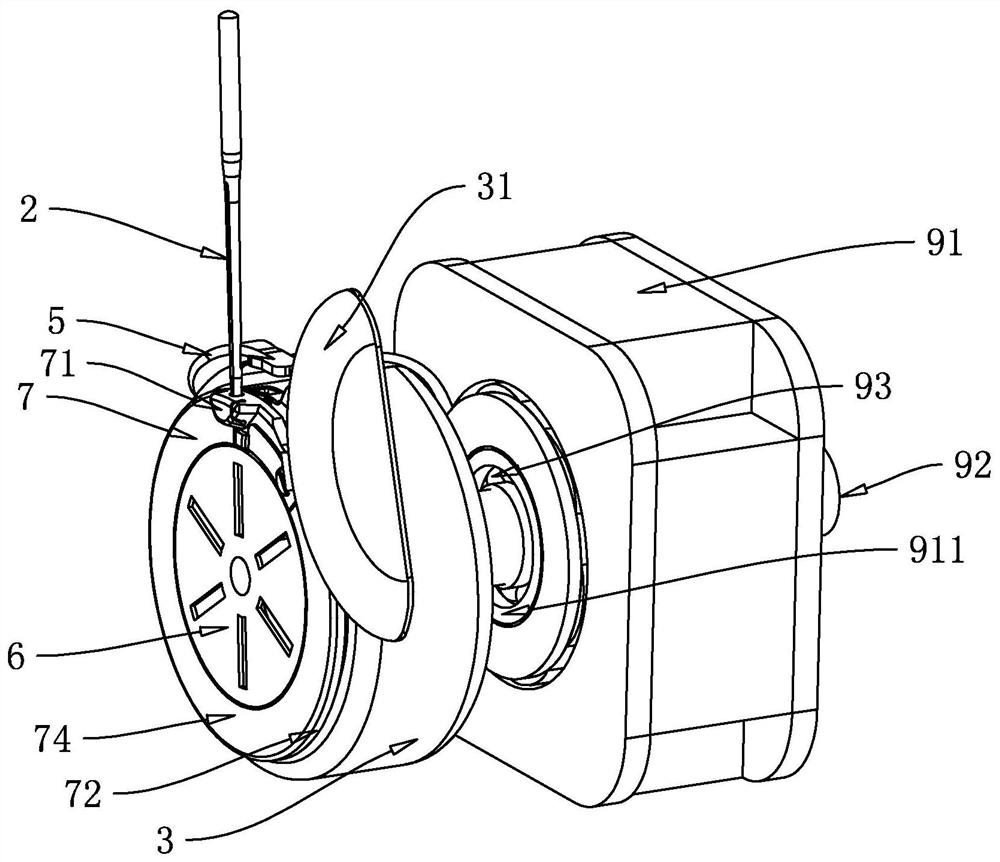

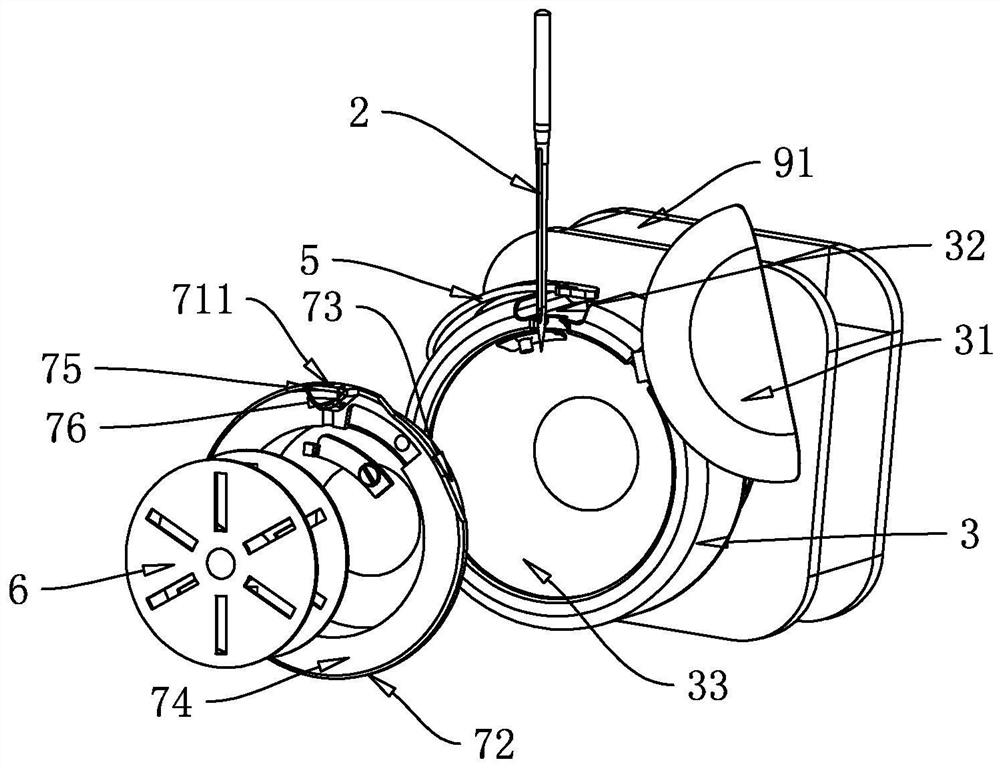

Suspension rotating shuttle for thread hooking

PendingCN114250556AExcellent mechanical transmission performanceImprove machine performanceLoop takersEngineeringSewing machine

Owner:QIXING INTELLIGENT TECH CO LTD

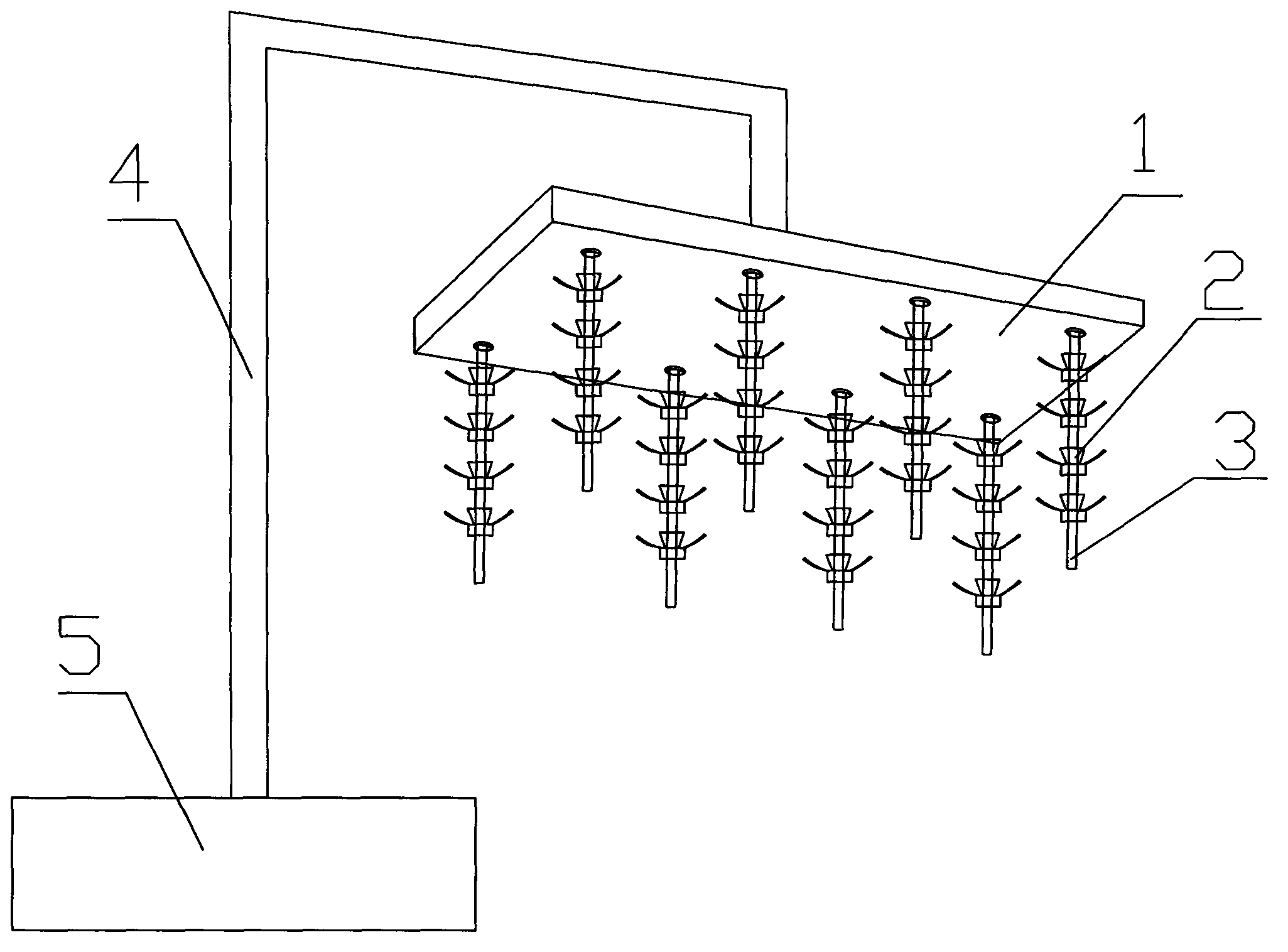

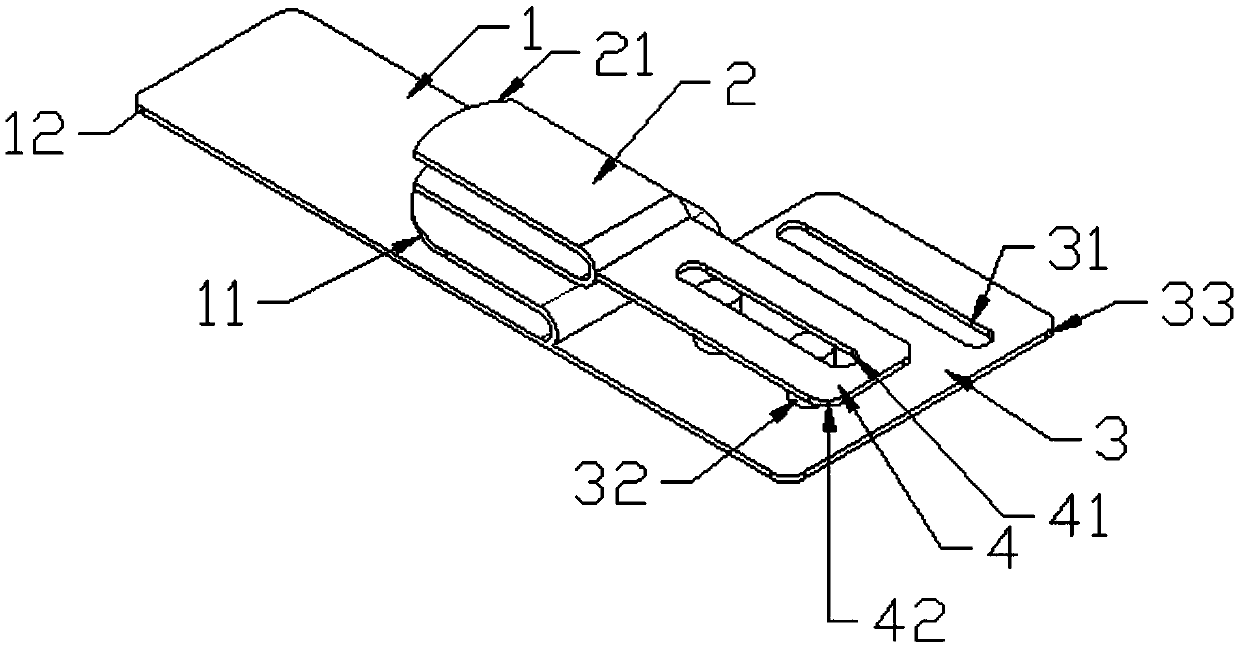

Hemmer of flat sewing machine

InactiveCN102330296ANot easy to curlNot easy to pile upWork-feeding meansBiochemical engineeringSewing machine

The invention relates to an auxiliary device of a sewing machine, in particular to a hemmer of a sewing machine. The hemmer comprises a bottom plate which is provided with a mounting hole and arranged on a lower dental plate of the flat sewing machine, and a horn-type winder which is arranged on the bottom plate and provided with an inlet end and an outlet end. The hemmer is characterized by also comprising a guide rod connected with the inlet end and a guide sheet arranged in the winder, wherein the guide sheet is held in the winder. The flat sewing machine hemmer is arranged on the flat sewing machine, so that artificial hemming is replaced; because the guide sheet and the guide rod are arranged in the hemmer, the cloth strip is difficult to curl or accumulate and smoothly enters the hemmer; the hemming size and width are consistent; and the hemmer has attractive appearance and reliable hemming quality, reduces the rework rate and greatly improves the work efficiency.

Owner:SUZHOU KENAN GARMENT

Liftable mechanism applicable to sewing machine

Owner:永康市睿趣学校用具有限公司

Transmission shaft support structure of sewing machine

ActiveCN110938947AImprove assembly accuracyLow machining accuracy requirementsSewing-machine control devicesEngineeringProcessing accuracy

Owner:ZHEJIANG BAOYU SEWING MACHINE

Sewing machine assembly line tool

The invention discloses a sewing machine assembly line tool. The sewing machine assembly line tool comprises a tool plate, a rotating mechanism arranged on the tool plate and an arc guide rail frame which is in butt joint with the rotating mechanism and used for fixing a sewing machine. The rotating mechanism comprises a gear motor and a flange plate connected with a rotating shaft of the gear motor, a locking mechanism is arranged between the rotating shaft of the gear motor and the tool plate, and locking and limiting to the rotating shaft can be achieved through the locking mechanism. The arc guide rail frame is fixed on the flange plate, and therefore the arc guide rail frame can rotate around the Y axis. At least two sets of arc guide rails are arranged on the arc guide rail frame, a fixing assembly used for fixing the sewing machine is arranged between the at least two sets of arc guide rails, and the at least two sets of arc guide rails can rotate around the X axis. According to the sewing machine placed on the assembly line tool, 360-degree rotation can be achieved in three-dimensional space, assembly and other work are greatly facilitated, and therefore the work efficiency is improved.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

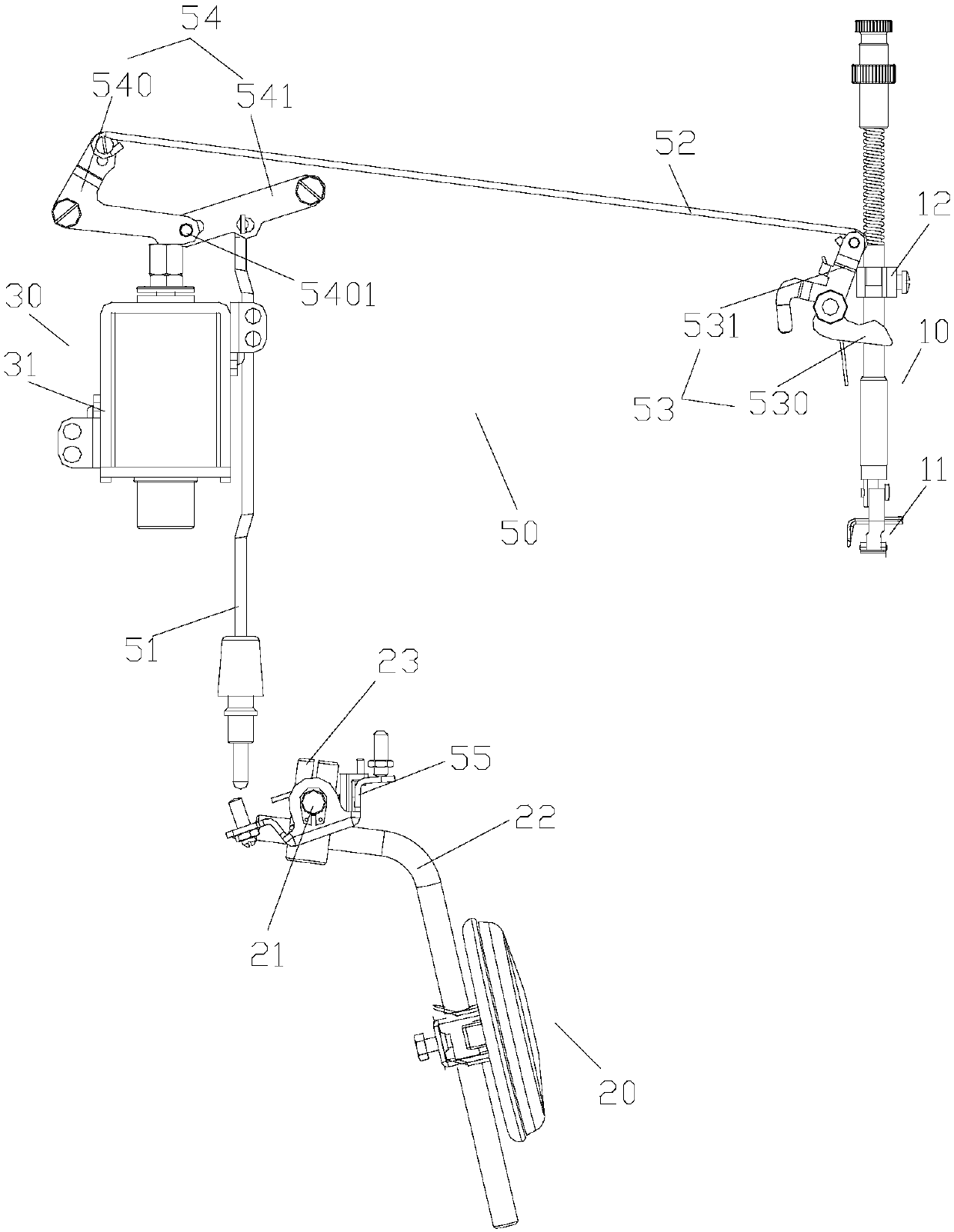

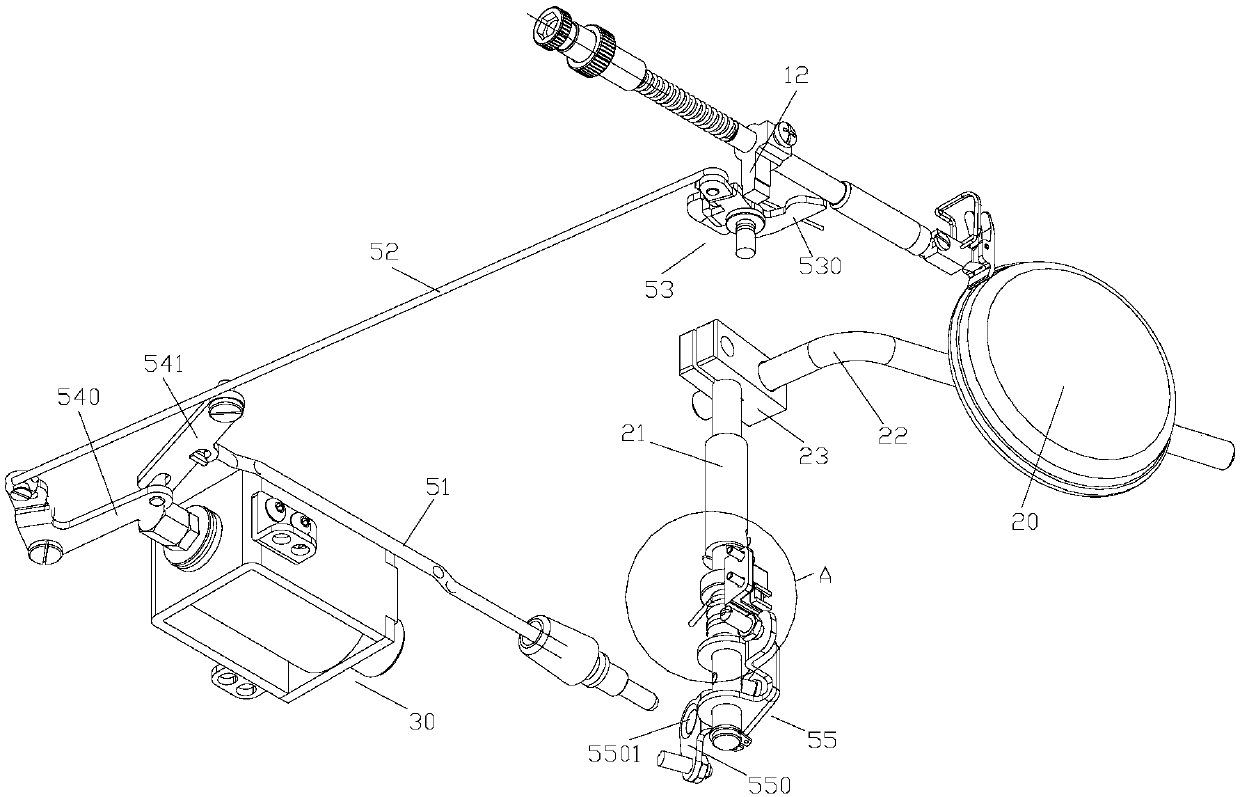

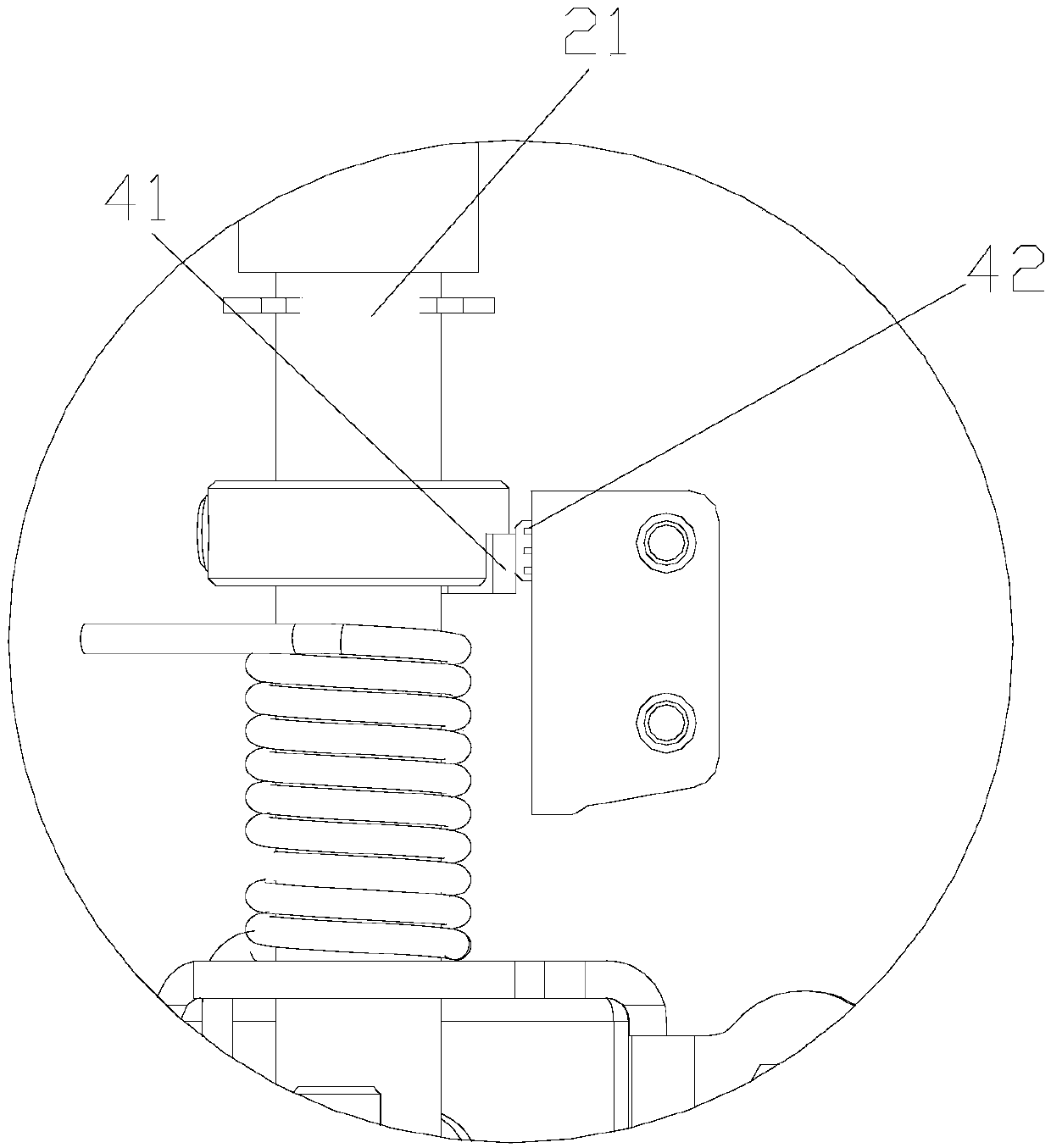

Presser foot mechanism and sewing machine with same

PendingCN111472105AImprove automation controlSolve the operation intensityPressersSewing machinePRESSURE FEET

The invention provides a presser foot mechanism and a sewing machine with the same. The presser foot mechanism is used for driving a presser foot rod provided with a presser foot to move so that the presser foot is lifted; and a guide frame is installed on the presser foot rod. The presser foot mechanism comprises a transmission assembly and a jacking part, wherein at least part of the transmission assembly is movably arranged and matched with the guide frame to push the guide frame to move through the transmission assembly, so that the guide frame drives the presser foot rod to ascend to liftthe presser foot; the jacking part is in contact with the transmission assembly, and at least part of the jacking part is telescopically arranged to push the transmission assembly to move; and the jacking part is connected with an electric control assembly, and the electric control assembly adjusts the lifting height of the presser foot rod by adjusting the telescopic amount of at least part of the jacking part to solve the problem that the operating intensity of a presser foot lifting mechanism in the prior art is high.

Owner:ZHEJIANG ZOJE SEWING MACHINE

Full-automatic template sewing machine for sewing down and feather filled products

InactiveCN105386246AReduce dependencySimplify complex processesProgramme-controlled sewing machinesEngineeringAtmospheric pressure

Owner:上工富怡智能制造(天津)有限公司

Sewing machine provided with flexible shaft

Owner:广东明德科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap