Overlock machine

An overlock sewing machine and sewing table technology, applied in the field of overlock sewing machines, can solve problems such as poor versatility, and achieve the effects of simple structure, good versatility and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

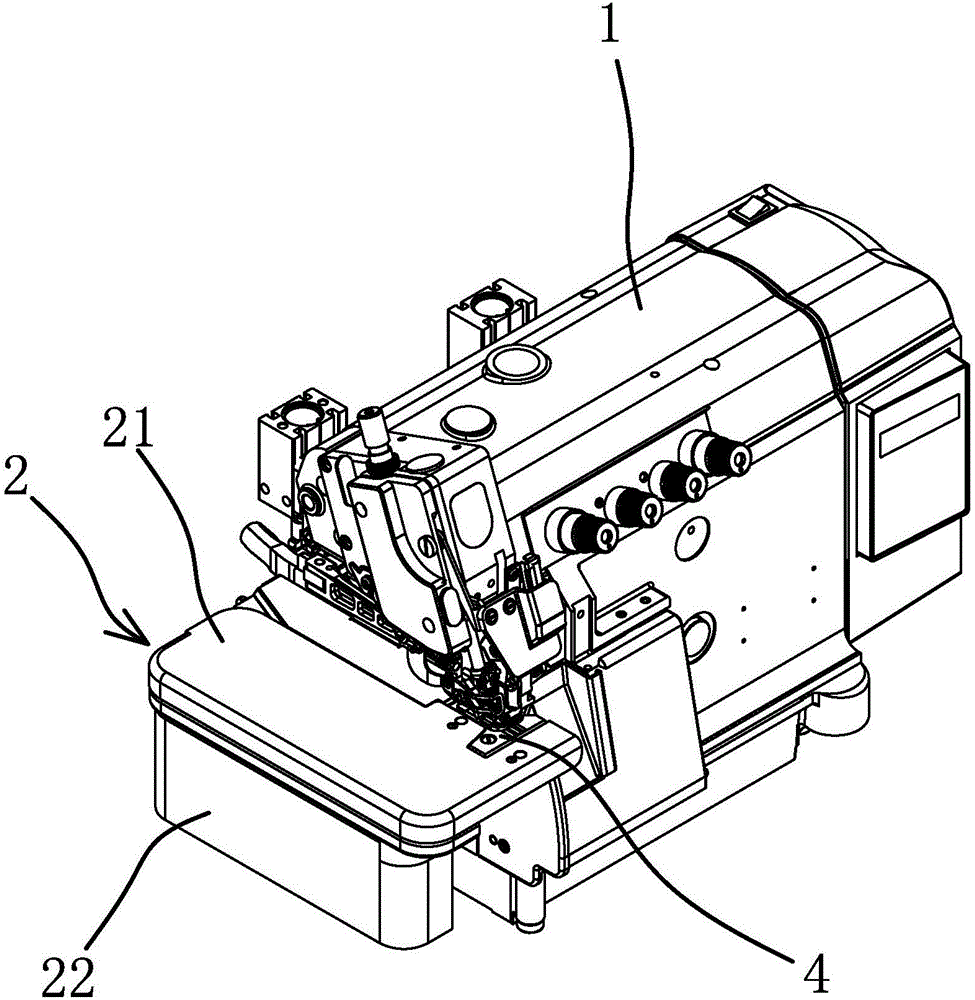

[0031] Such as figure 1 , figure 2 As shown, the overlock sewing machine includes a main body 1, a workbench 2, a needle plate seat 3, a needle plate 4, an end cover 5 and an articulated arm 16.

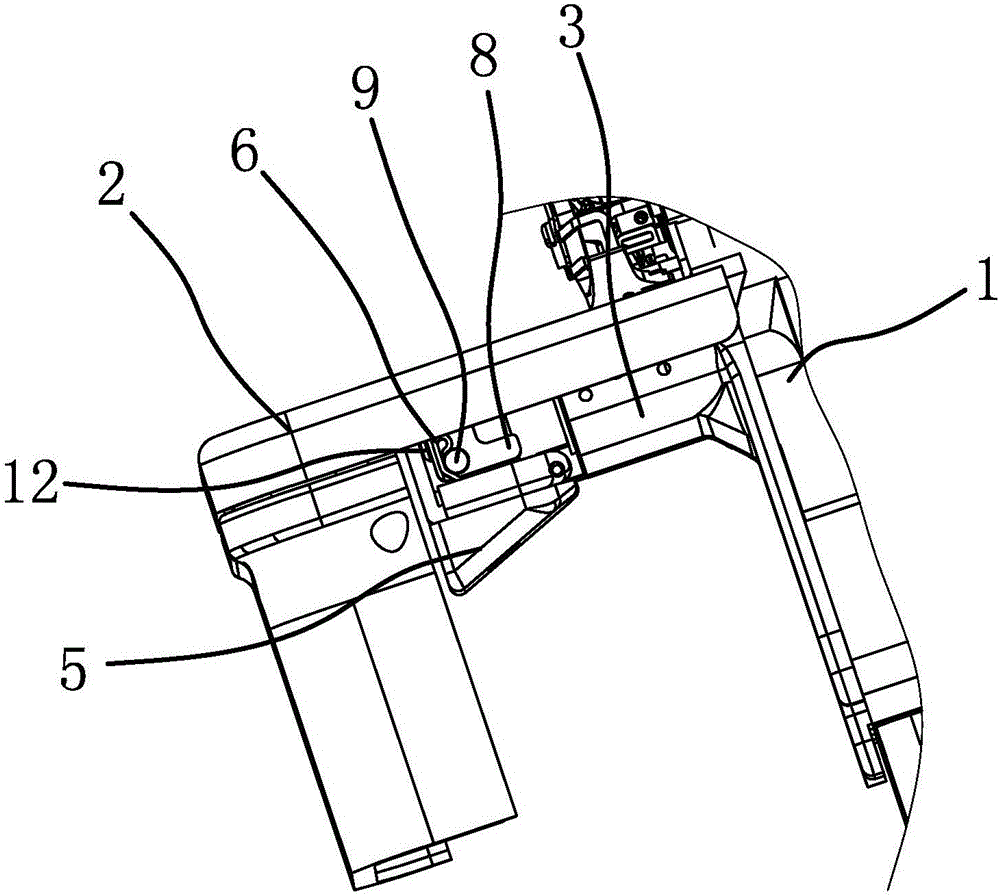

[0032] Articulated arm 16 is fixedly connected on the left end of main body 1, as Figure 5 As shown, the workbench 2 includes a panel 21 and a cross cover 22, the articulated arm 16 is hinged to the panel 21 through a pin shaft, the cross cover 22 is fixedly connected to the edge of the bottom of the panel 21, and one side of the workbench 2 has a protruding portion 15 . The bottom of the workbench 2 is fixedly connected with a clamping seat 8, and the clamping seat 8 is fixedly connected with a cylindrical bayonet pin 9, and the bottom of the clamping seat 8 is fixedly connected with a first permanent magnet 10, and the side of the clamping seat 8 A buffer pad 12 is fixedly attached to the wall.

[0033] The needle plate seat 3 is U-shaped, and the needle plate seat 3 is fixedly

Embodiment 2

[0038] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the end cover 5 and the clamping seat 8 can be detachably fixed by bolts, and the end cover 5 and the needle plate seat 3 can be connected by The bolts are detachable and fixed.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap