Presser foot mechanism and sewing machine with same

A technology of presser foot lifter and presser foot lever, which is applied in the field of presser foot lifter mechanism and sewing machines with it, can solve the problems of high operation intensity, achieve the effects of reducing work intensity, increasing automatic control, and solving the effect of high operation intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

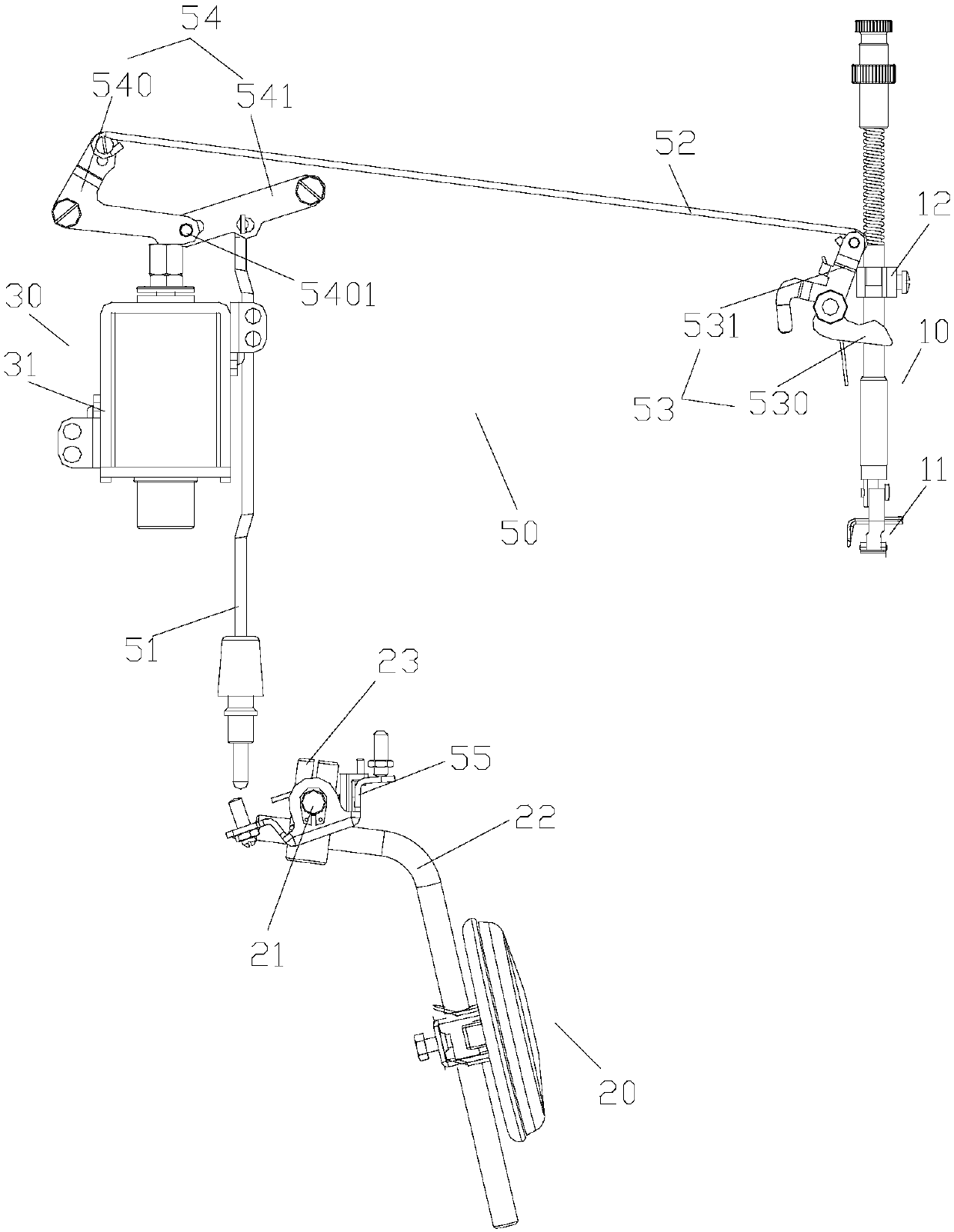

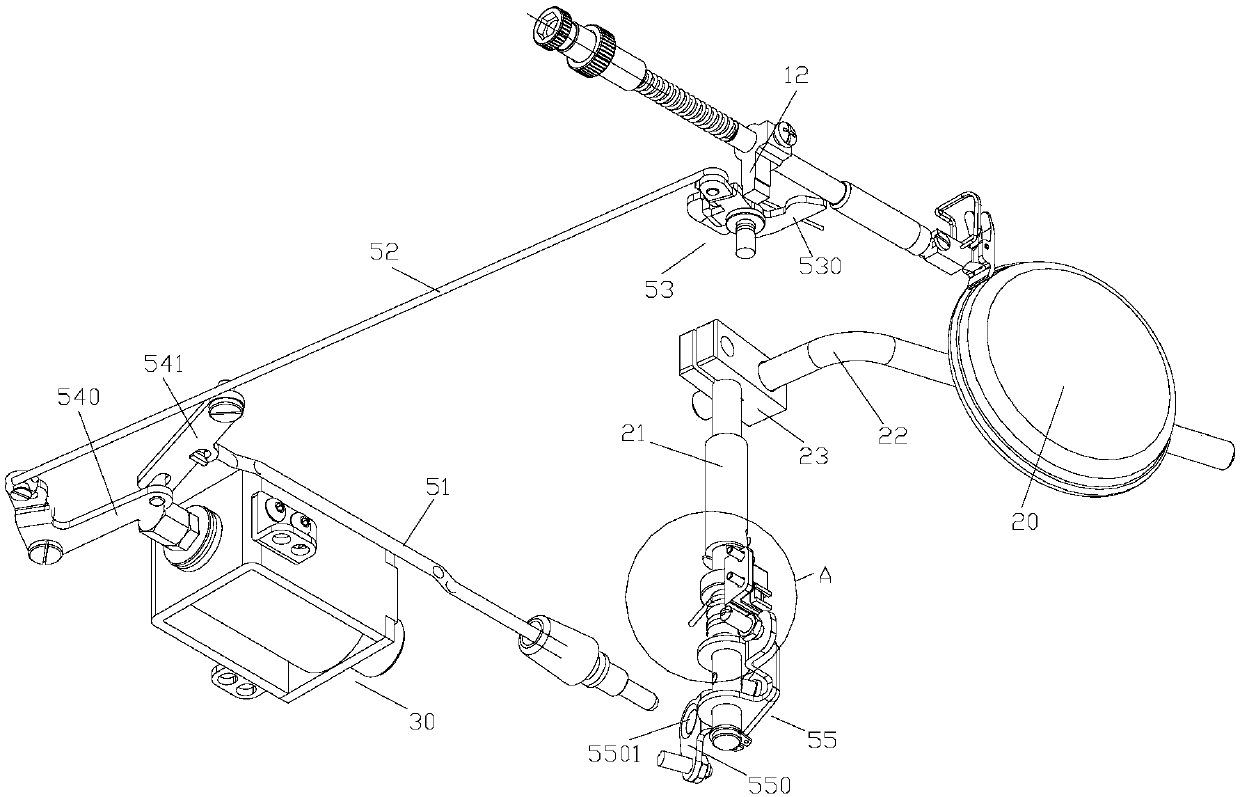

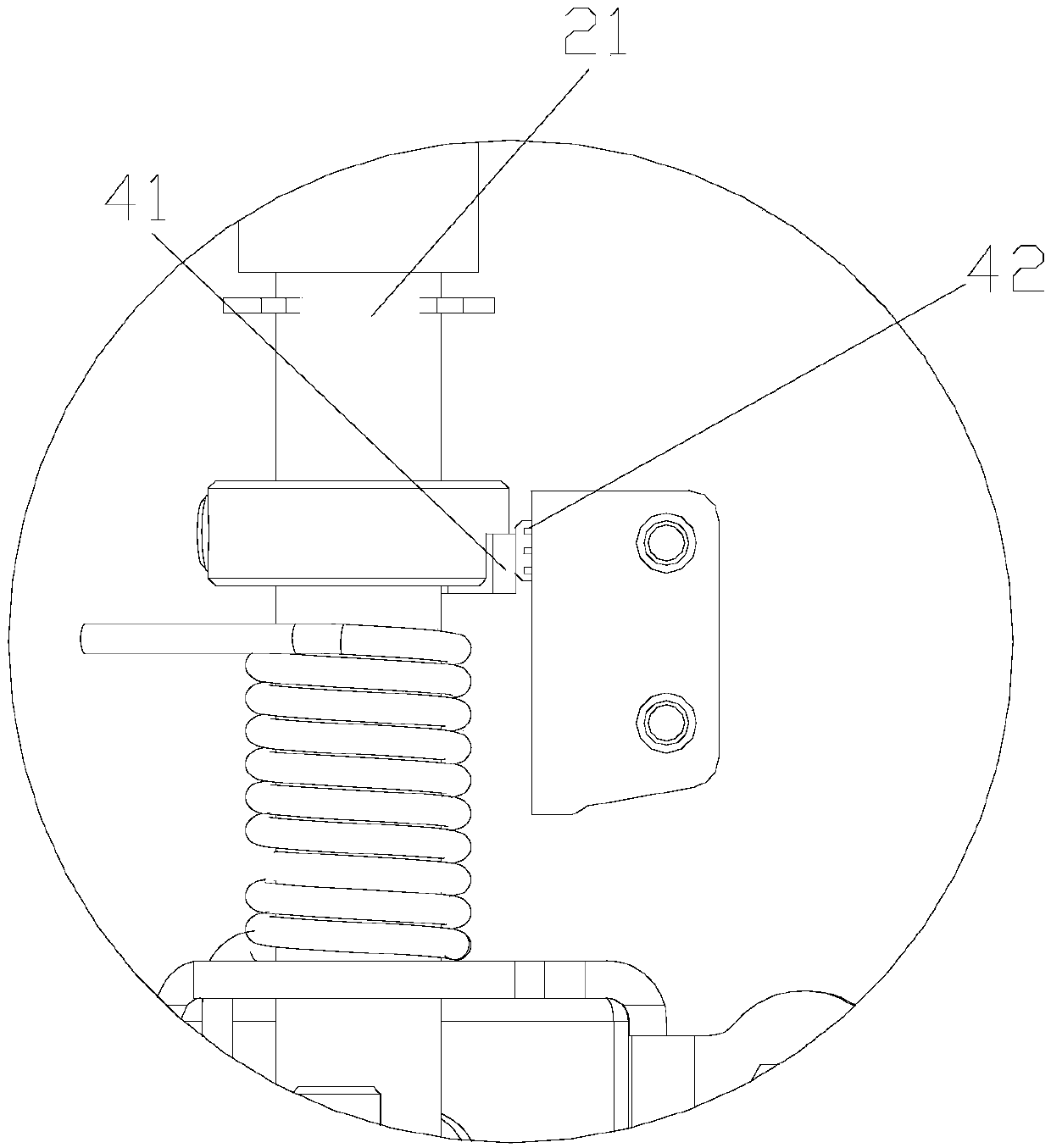

[0025] The present invention provides a presser foot lifting mechanism, please refer to Figure 1 to Figure 3 , used to drive the presser foot rod 10 mounted with the presser foot 11 to move to realize the presser foot lifting action, the guide frame 12 is installed on the presser foot rod 10, the presser foot lifting mechanism includes: a transmission assembly 50, at least part of the transmission assembly 50 can be Set in motion and cooperate with the guide frame 12 to push the guide frame 12 to move through the transmission assembly 50, so that the guide frame 12 drives the presser foot bar 10 to rise to realize the action of lifting the presser foot; the jacking part 30, the jacking part 30...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap