Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9 results about "Mechanical transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mechanical transmission of disease. Mechanical transmission of disease pathogens occurs when a vector transports organisms, such as bacteria that cause dysentery, on its feet, body hairs and other body surfaces to the host.

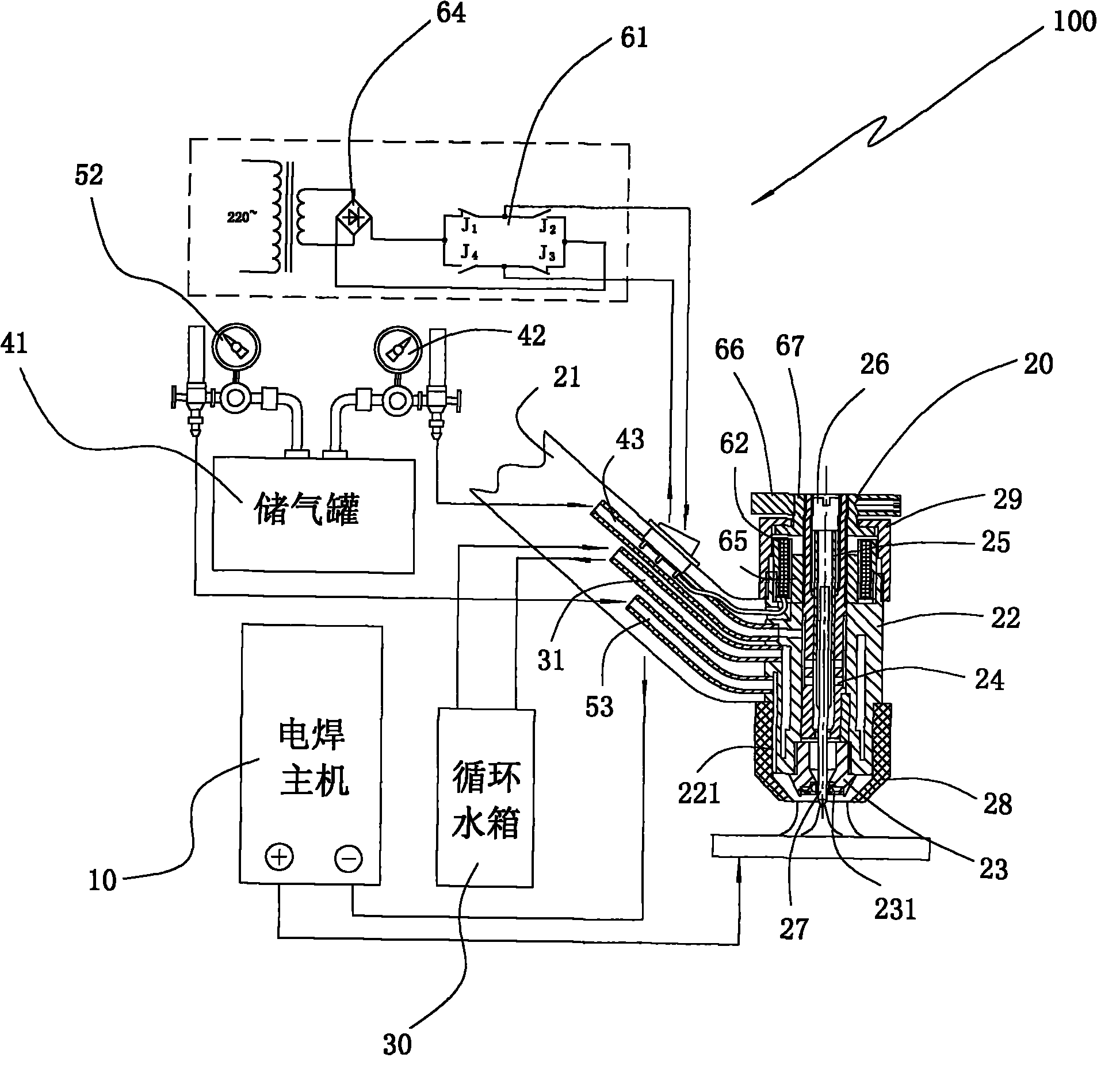

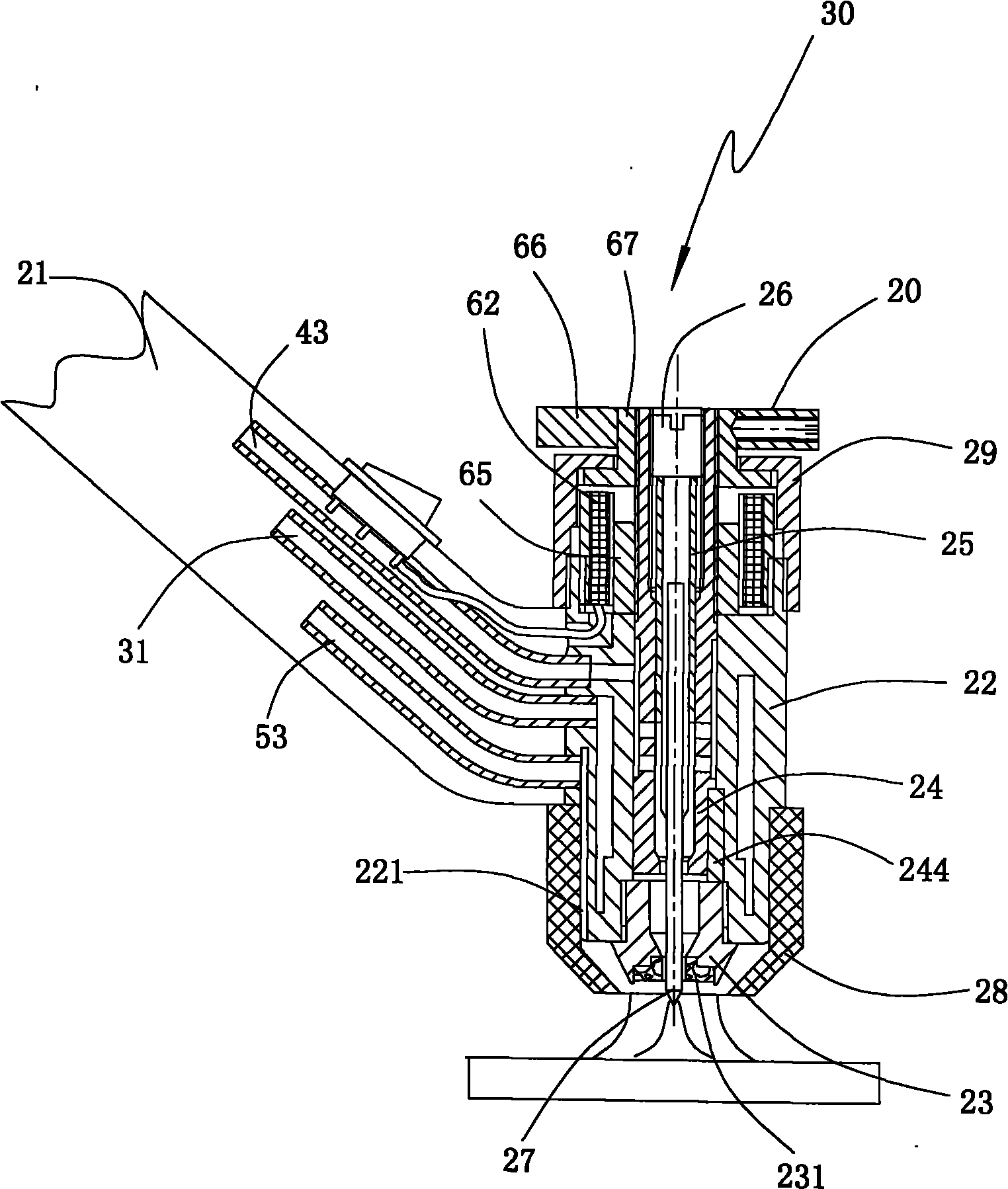

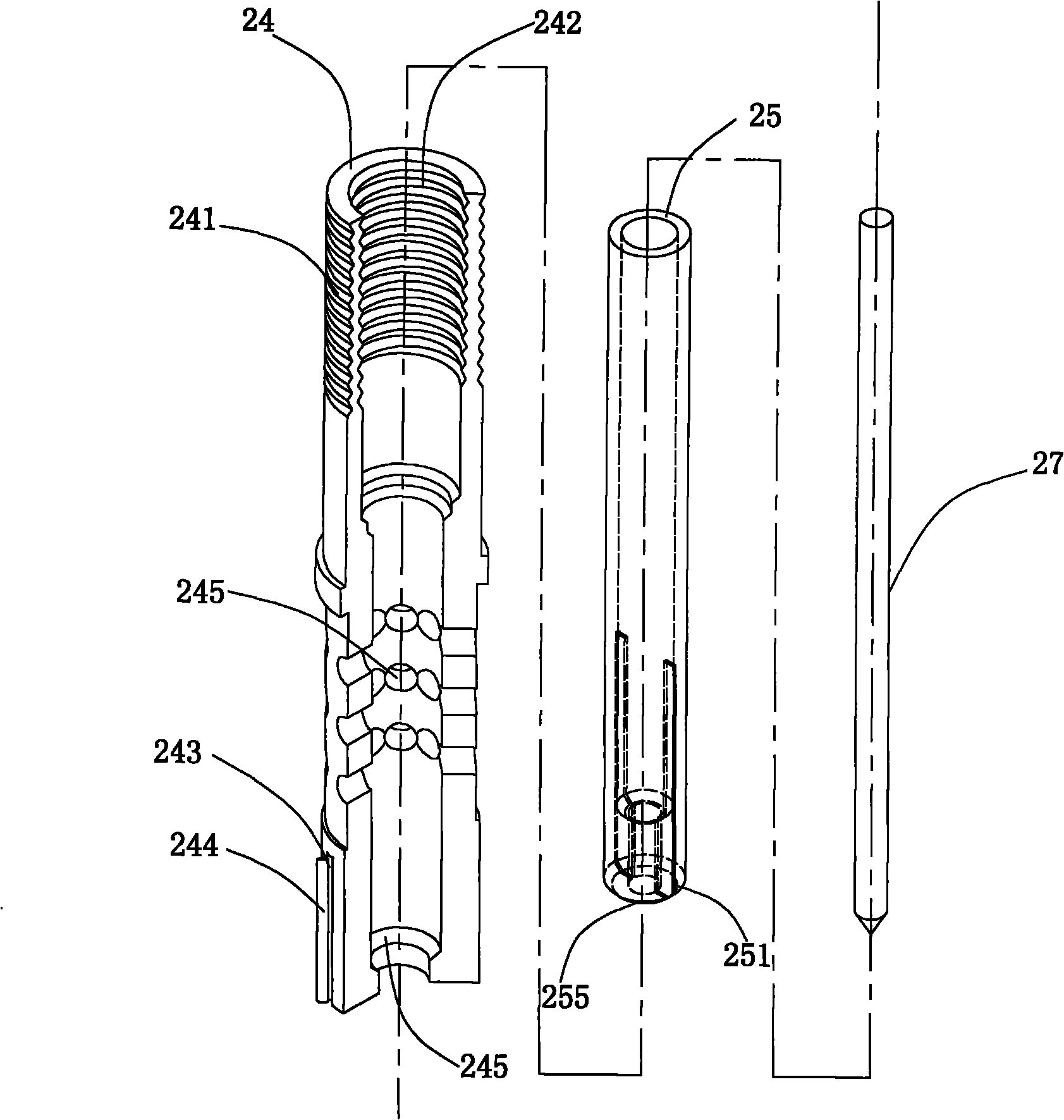

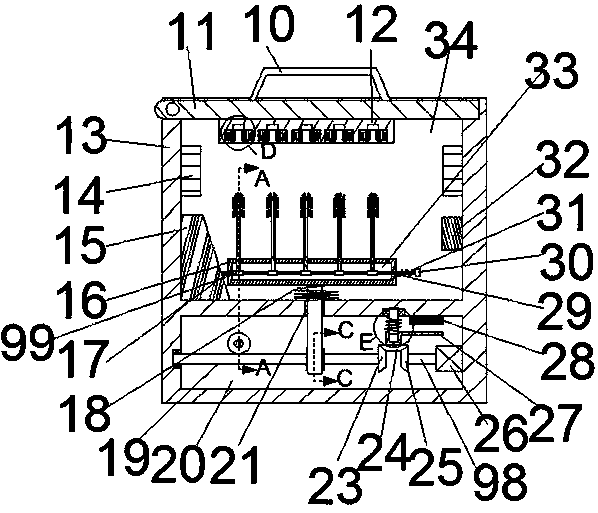

Inverter electric welding machine device with adjustable electric arc

InactiveCN101823176AImprove stabilityImprove practicalityElectrode vibration holdersShielding gasCompression screw

Owner:上海新亚电焊机有限公司

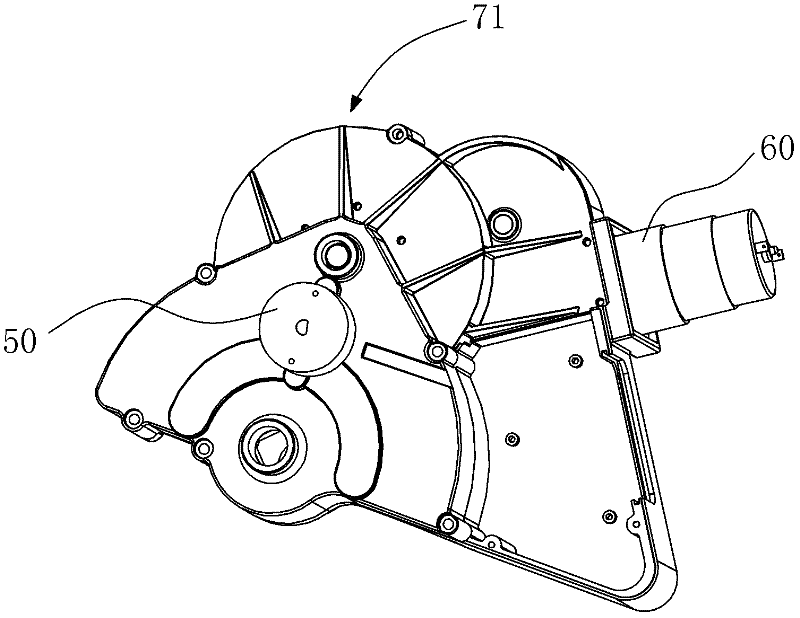

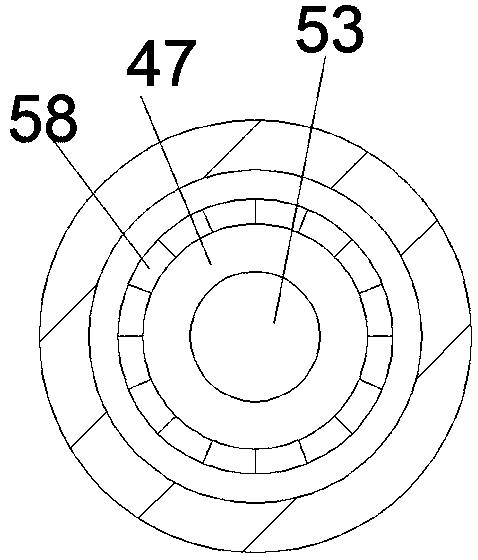

Speed reducer

ActiveCN102518753AMeet the transmission requirements of large reduction ratioSmall footprintToothed gearingsPower-operated mechanismThree stageReduction drive

Owner:CHERY AUTOMOBILE CO LTD

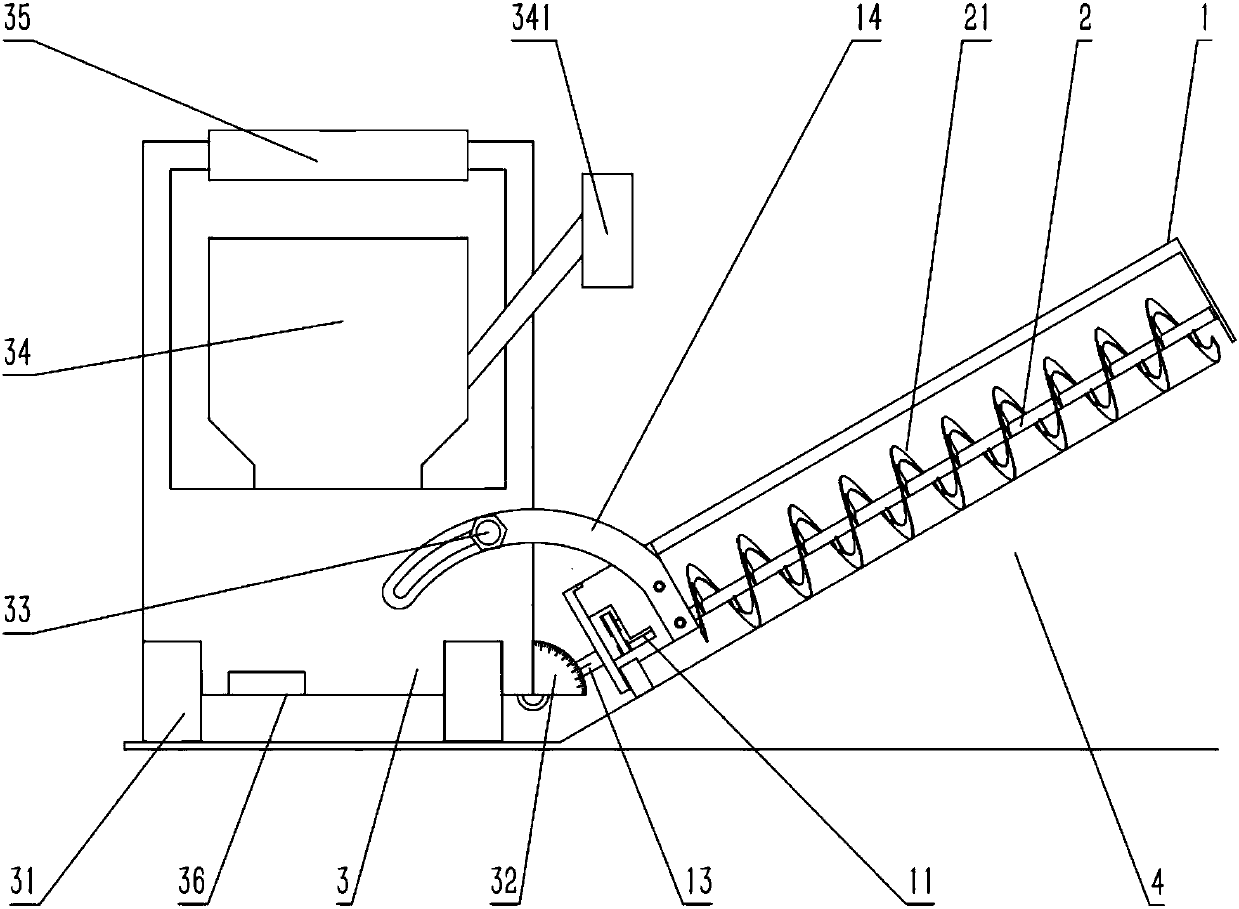

Slope sediment leveler

InactiveCN107620454AImprove the level ofIncrease moisture contentBuilding constructionsLeveling effectEngineering

Owner:刘有生

Crystal merry-go-round music box

InactiveCN110364130AOvercome the shortcoming of single functionReduce the possibility of errorAutomatic musical instrumentsEngineeringSpecial effects

Owner:XIANGSHAN YOUCHENG CRYSTAL CO LTD

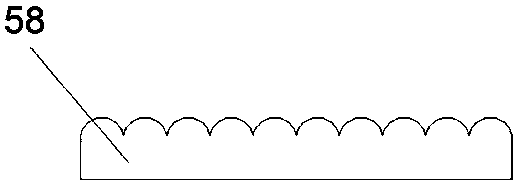

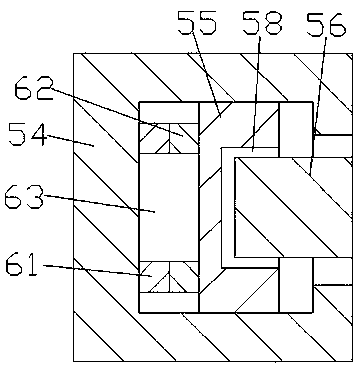

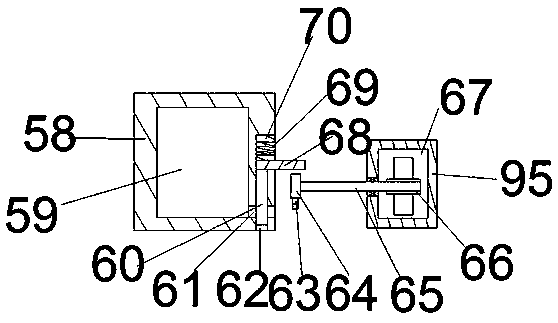

Mechanical transmission structure of electronic booster

PendingCN109177959ASolve the problem that the brake will also failSimple structureBraking action transmissionEngineeringBraking system

Owner:SHIJIAZHUANG JIAXIN AUTOMOTIVE BRAKE SYST

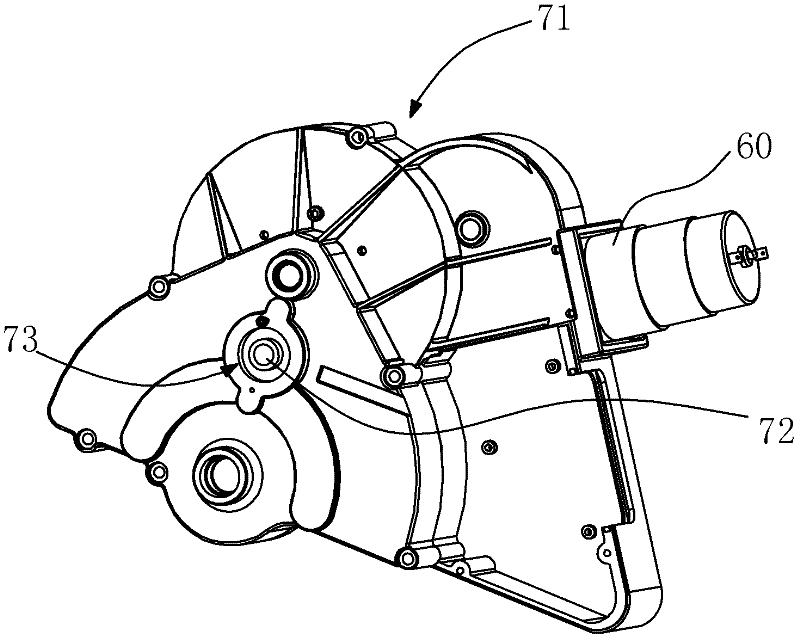

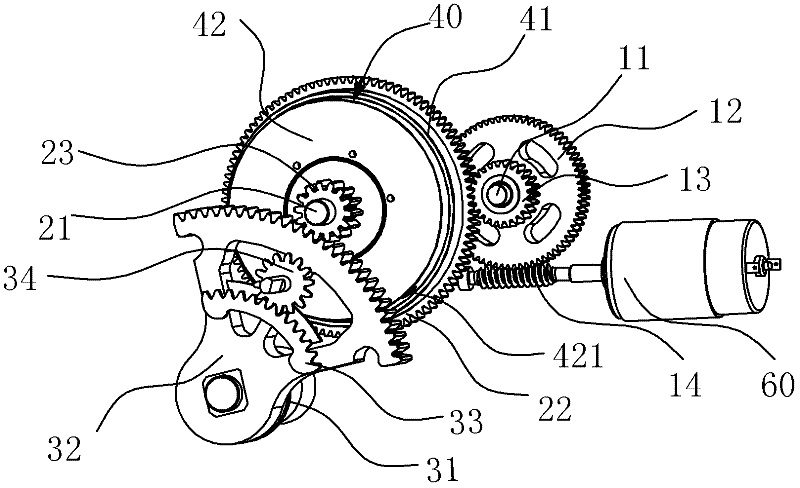

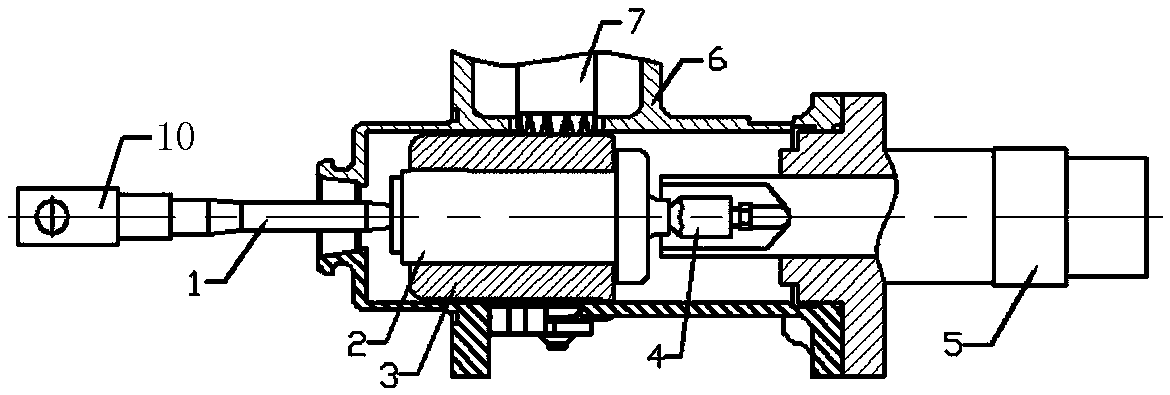

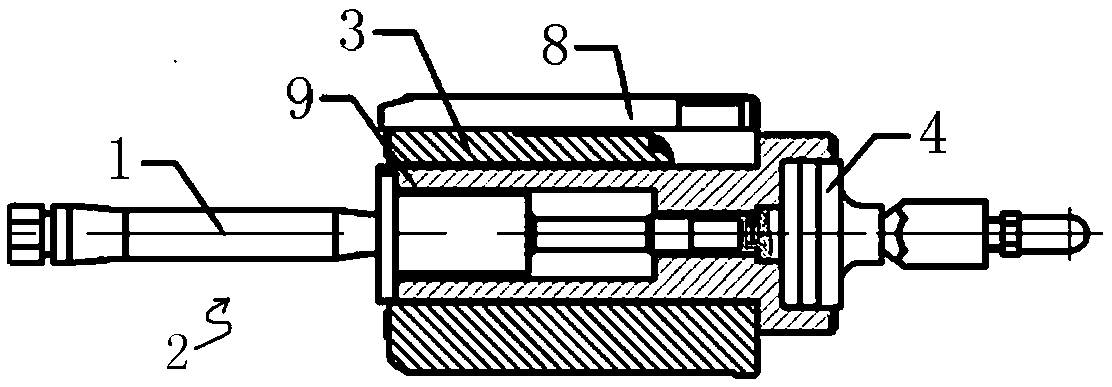

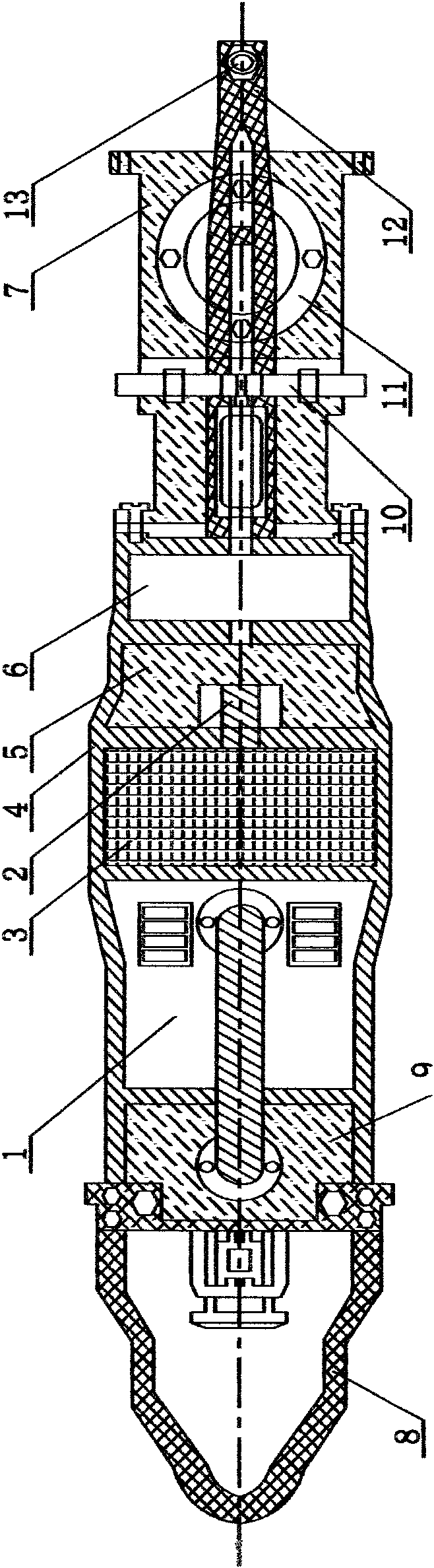

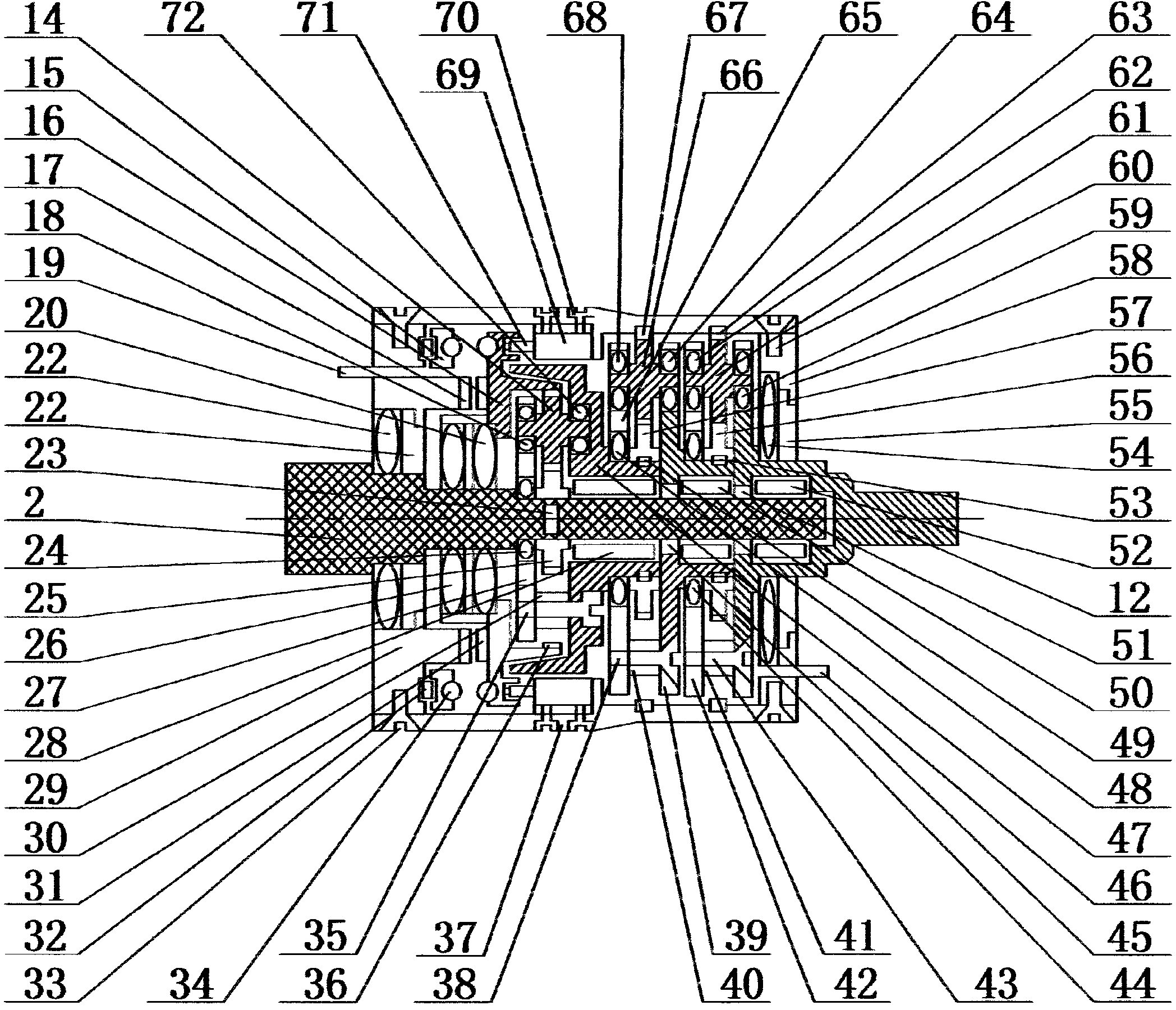

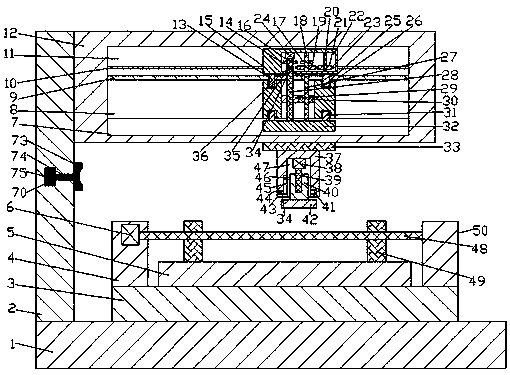

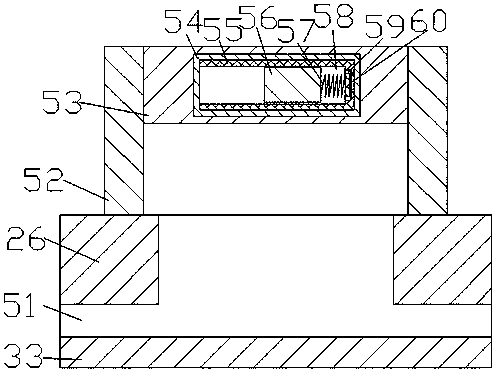

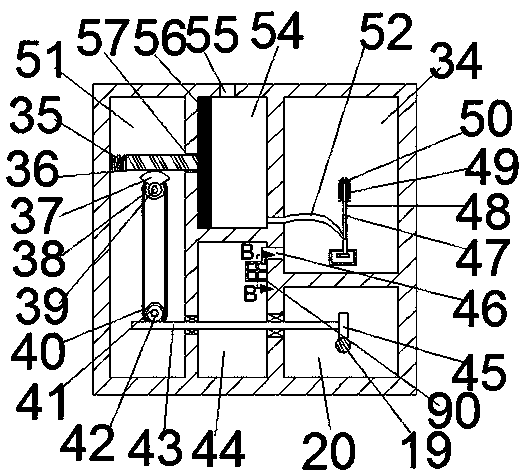

Servo mechanical transmission special for top drive drilling machine

InactiveCN103670265ATightly boundStrong output torqueConstructionsToothed gearingsElectric machineThrust bearing

Owner:河北格洛斯节能设备科技股份有限公司

Processing method for cross section hard wood floor blocks based on bioengineering

InactiveCN108748582AGuaranteed smoothSimple structureWood working apparatusEngineeringFront and back ends

Owner:王若云

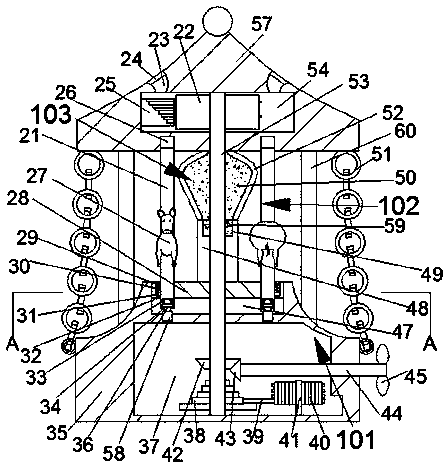

Cleaning device for biological reagent test tube

InactiveCN111330927AEasy to cleanReduce pollutionHollow article cleaningWater storagePower apparatus

Owner:周凤兰

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap