Mechanical transmission structure of electronic booster

A technology of mechanical transmission and booster, applied in the direction of brake transmission, brake, transportation and packaging, can solve problems such as failure of automobile brakes, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

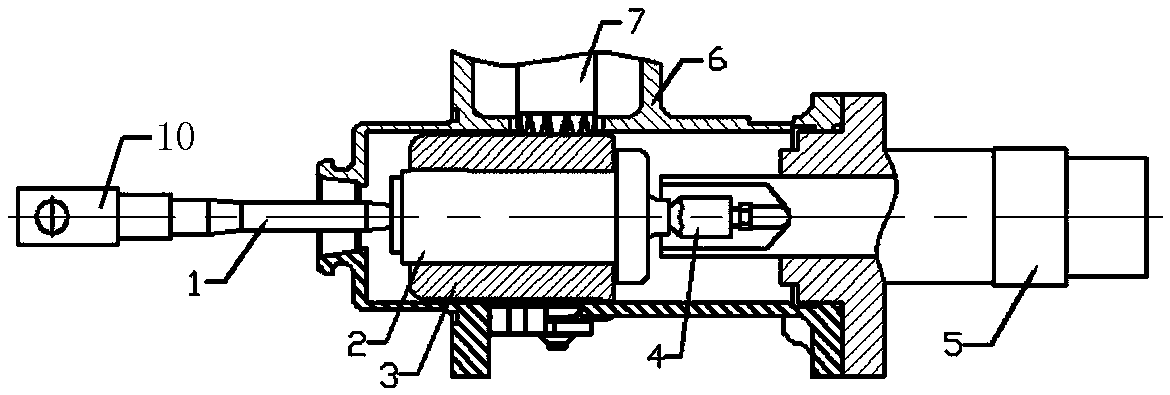

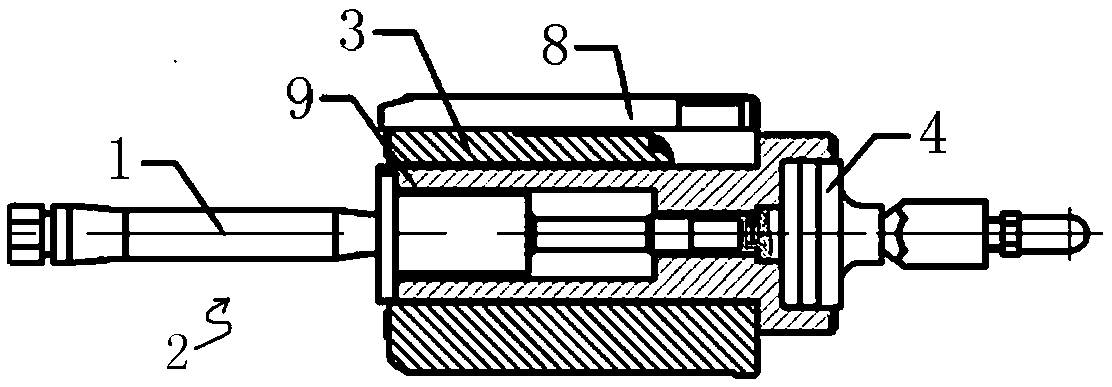

[0021] like figure 1 and figure 2 As shown, the mechanical transmission structure of the electronic booster of the present invention includes a cylinder block 6, a motor booster mechanism 7 arranged on the cylinder block, a valve body assembly 2, a gear sleeve 3 and a sensor 8 arranged inside the cylinder block 6, and A controller (not shown in the figure) connected to the motor assist mechanism 7 .

[0022] The cylinder block 6 is a horizontal cylinder barrel, one end of the cylinder barrel is provided with a push rod inlet, and the other end is provided with a brake master cylinder inlet. The valve body assembly 2 is arranged inside the cylinder along the axial direction of the cylinder, and the valve body assembly 2 can move along the axial direction of the cylinder under the action of external force. The valve body assembly 2 includes a valve body 9 , a push rod 1 and an output rod 4 . The valve body 9 is a hollow tubular structure, the gear sleeve 3 is set on the peri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap