Novel spool creel

A spool rack and a new type of technology, applied to the field of spool racks, can solve the problems of insufficient space utilization, inconvenient operation for changing spools, and lower production efficiency, and achieve the effects of saving space, facilitating access and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

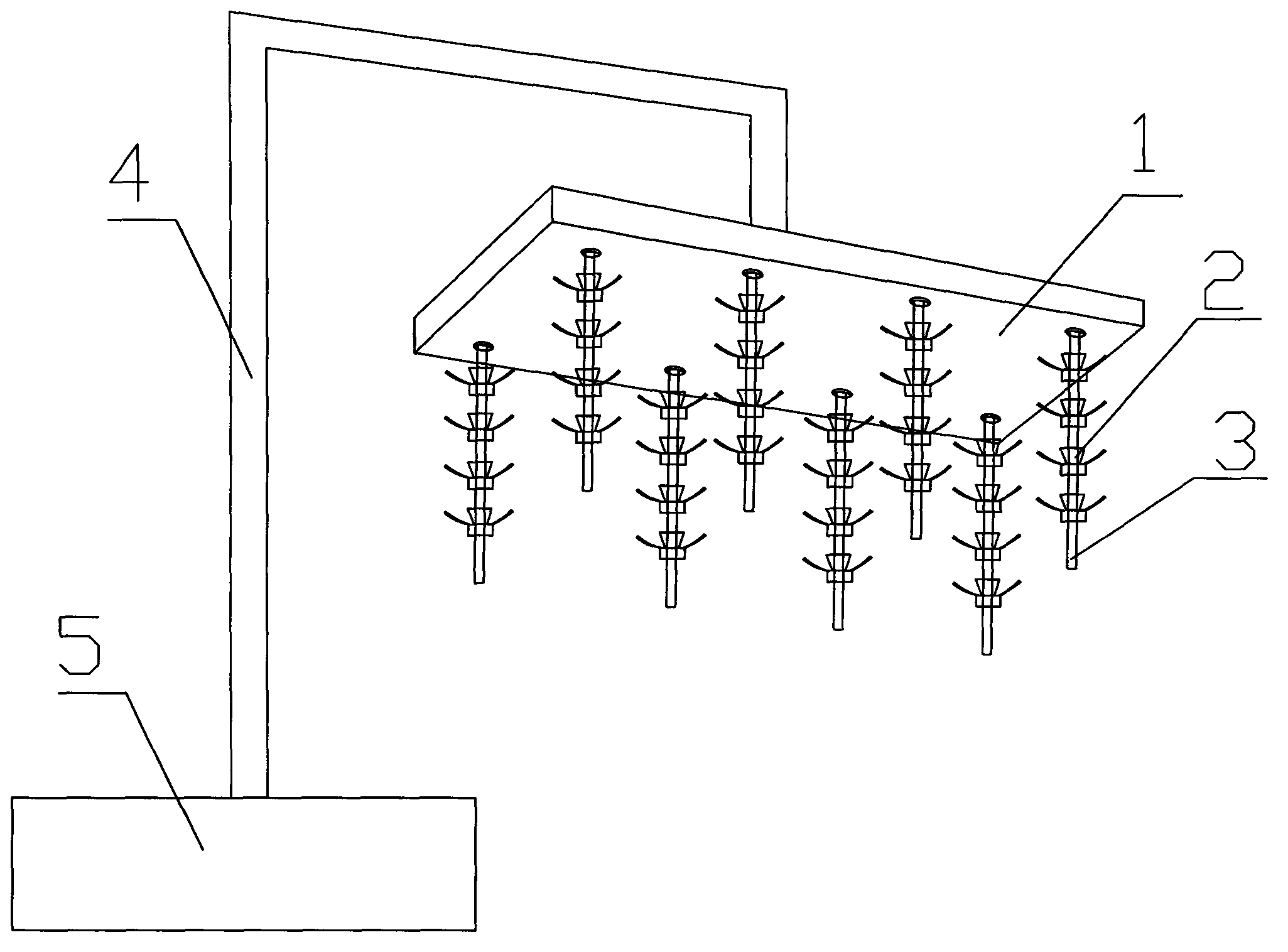

[0015] Such as figure 1 As shown, a new type of bobbin frame includes a support plate 1 and 24 wire posts 3, the line posts 3 are installed on the lower surface of the support plate 1, and each thread post 3 is equipped with a buckle device 2. In this embodiment, an elastic ring made of elastic material matching the wire post (3) is selected, and the elastic ring is provided with a number of shrapnels on the outer surface of the elastic ring, so that the elastic ring presents a barbed tooth structure. The elastic ring is tightly clamped on the wire post 3 and is slidably matched with the wire post 3 . The upper surface of the supporting plate 1 is fixed on the support 4 above the sewing machine platform 5 .

[0016] The new bobbin stand adopts the combination of the downward thread post and the buckle device, which can firmly fix the bobbin and conveniently pull out the thread end for use; moreover, the supporting plate of the new bobbin stand is fixed on the bracket above the s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap